Click to Chat

I'm online now.

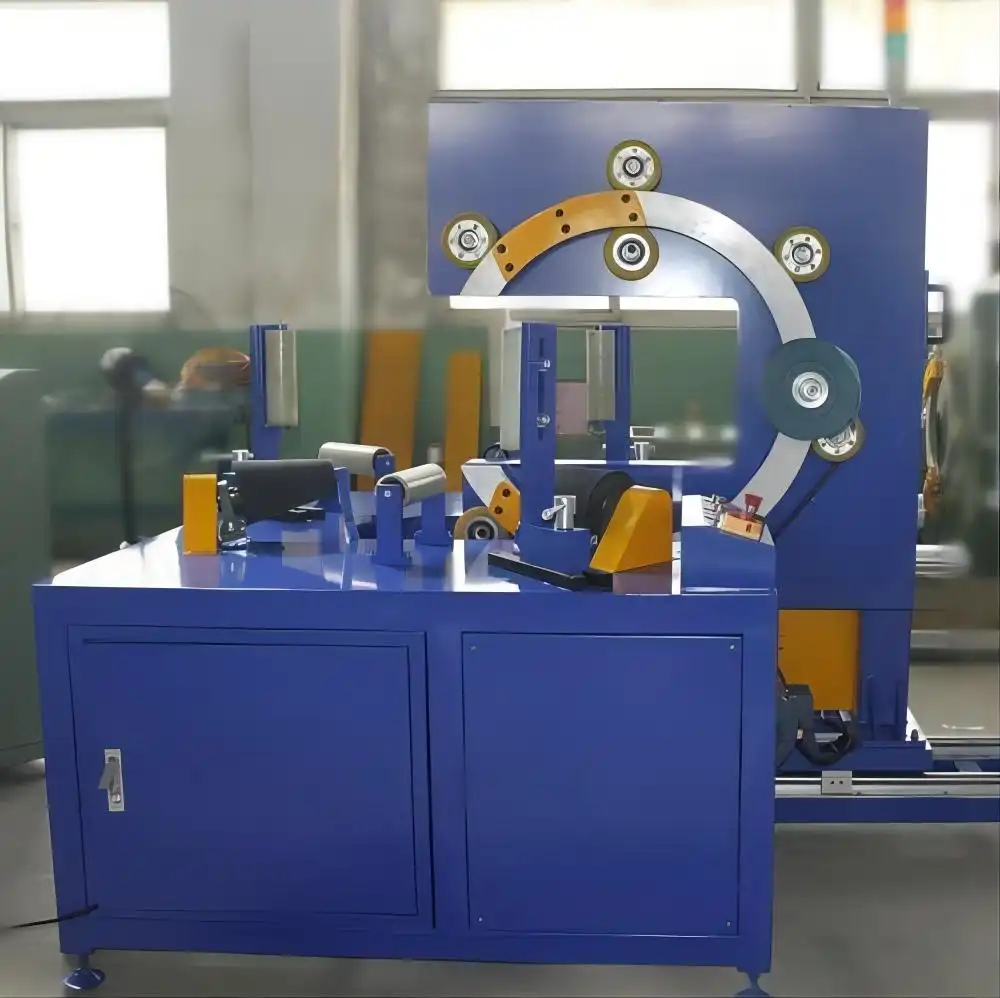

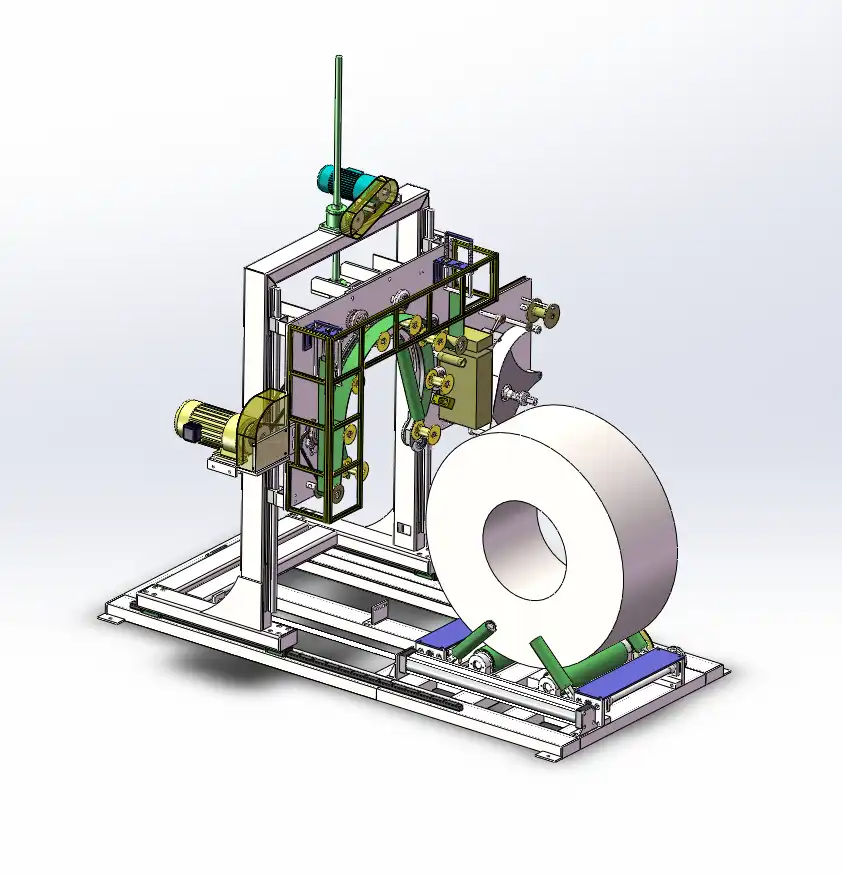

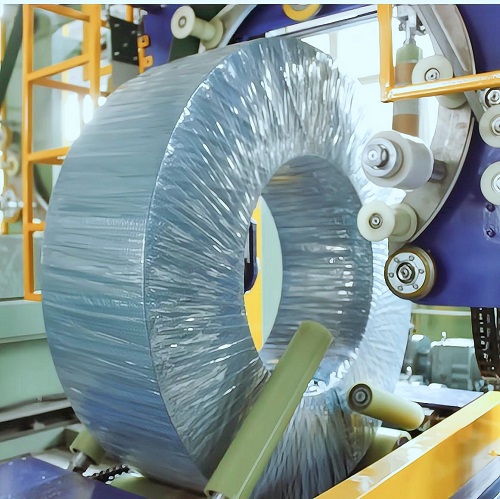

The Coil packing machine is a ring type stretch wrapper special designed for eye through film wrapping which is an efficient equipments for coils packaging. There are different vertion coil stretch wrapper per diferent coil size, handling way, packing material and handling requirement. At Fhope different types coil packaging solution is avialable for a nice and uniform packaging for many products in coil side, such as hose coil, pipe coil, wire coil, bearing, cable... Find more applicatoin.

Our team have rich experience in the coil packaging solution that we provide more than 1200 sets coil packing equipment aroud the world which works for improving the packing speed and replace the manually work. Click here for 100+ sets coil wrapping machine gallery

And our team got rich experience on customized designing for the customer around the world. Now Fhope had deliveried coil packing machines more that 1654 sets to the 65 countries.

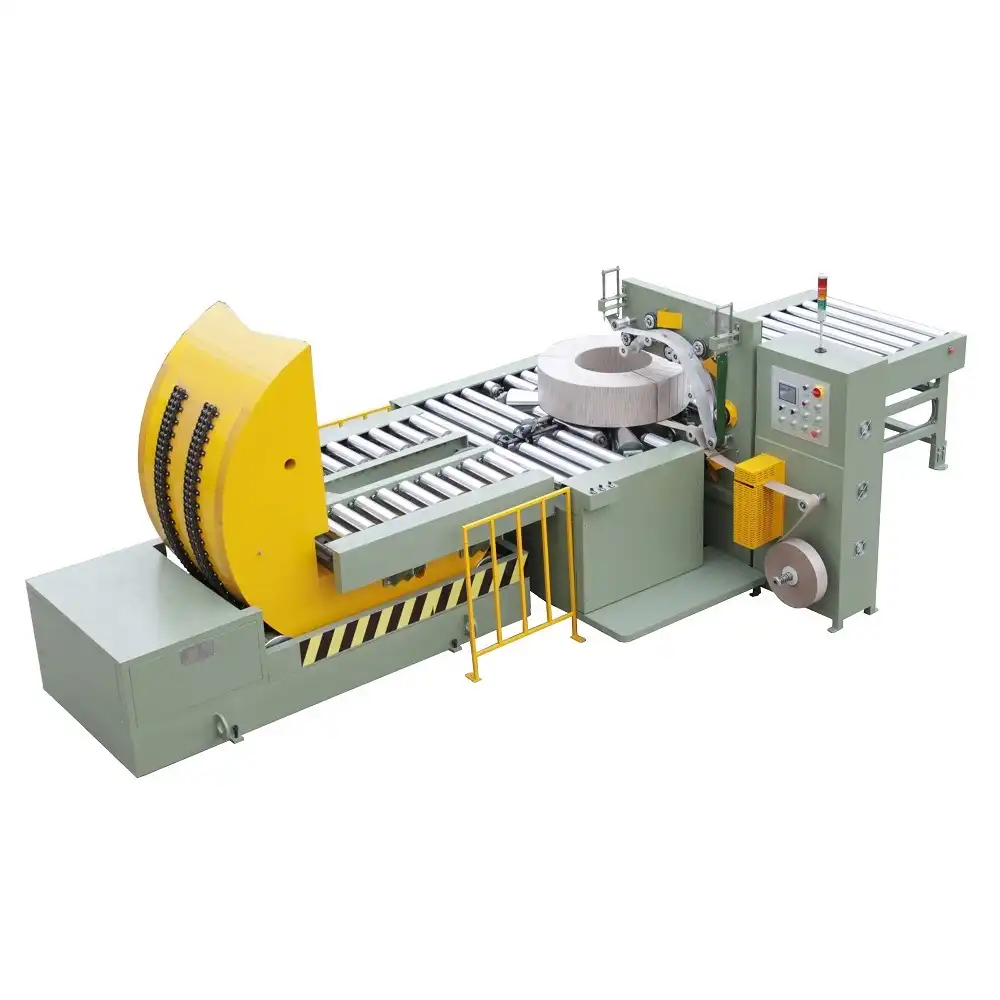

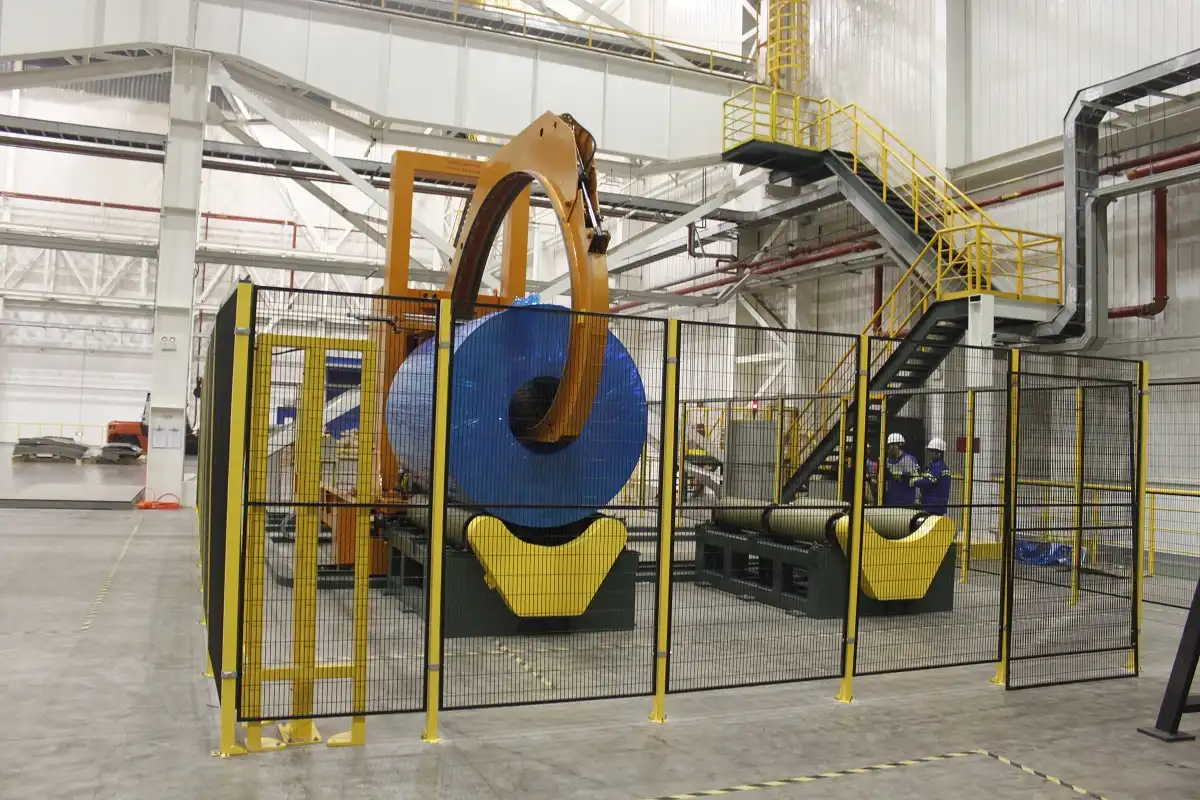

New coil packing line for strip coils after slitting and shearing. Fully automated from coil turning to packing and stacking. Features heavy-duty turnstile (2/4 a...

Coil wrapping machine--FPS-800 designed for slited steel coil,copper coil package,wire coil package... with max.width 800mm Weight 400kg by film,paper,HDPE...The ...

The steel coil wrapping machine is a reliable and efficient solution for packaging coils of various sizes. With high-quality components and adjustable settings, i...

FPS-500 series steel coil packaging machine is a equipment for flexibility, Low Maintenance and High Operating Speed. It is highly efficiency and good in nice coi...

FPS-400 series steel coil packing machine is mainly used to steel coil, steel strip packaging, which is with highly efficiency and nice packaging for saving labor...

FPS-300 steel coil wrapping machine is equipment designed mainly used to packaging solution of steel wire coil, copper coil. It is an highly efficiency equipment...

This horizontal type coil packing machine is ideal for packing steel strips and slitting coils using paper, stretch film, and other materials. It is designed to p...

Master steel coil stretch wrapping machinery for master steel coil eye through wrapping by VCI film. The solution represents a major advance in the power connecti...

FHOPE pack has designed a steel coil wrapping and packing machine which consists of an upender, a coil station, and a wrapping packing system that uses various ma...

Automatic hose/Pipe coiling and strapping machine and automataic pipe coiler for winding the HDPE PIPE, Corrugated coil packaging from automatic winding machine t...

Automatic hose coil packing line designed for corrugated hose coil, PVC pipe coil, PE pipe coil packaging.It is a horizontal type coil stretch wrapper for online ...

The hose coil packing machine features a conveyor in the wrapping station which can be connected to an automatic coiler and downender for inline coil packing. Thi...

This hose coil packing machine is designed for horizontal packing of soft coils. It provides excellent support to prevent deformation during the packing process. ...

A horizontal coil wrapping machine rotates hose, cable, or pipe coils 360 degrees to wrap them in stretch film or paper. The machine securely binds coils from end...

Hose coil wrapper,pipe coil wrapper,hose pipe packing machine adopts streth film,HDPE,woven...is able to provide a nice anti moisture,anti dust package for plasti...

Hose Coil wrapping machinery FPH-400 is mainly used to hose coil, plastic pipe packaging requirement, which is with highly efficiency and nice packaging for savin...

FPH-300 Hose coil wrapping machine, saves your four staff in corrugated hose wrapping!!!FPH coil stretch wrapper and equipment working for your film stretch wrapp...

One hose coil packing machine save your four staff in wrapping!!!FPH Hose coil wrapping machine with packing speed upto 15-25sec/pcs for hose coil,pvc pipe,hdpe p...

The coil wrapping machine is equipped with a tension controller and a press-down device that efficiently wrap light and small hose coils as well as PVC pipe coils...

Our corrugated hose stretch wrapping machine is specifically designed to efficiently wrap light hose coils with stretch film. With a wrapping time of just 15-20 s...

The horizontal PC wire coil packing machine is designed for steel wire coils with outer diameters of up to 2500 mm and weights of 1 to 3 tons. It is a ring-type c...

Both semi-automatic and full-automatic type can be provided. Specific design and plan will be made by our engineering team according to the data provided by the c...

The FPW-800 is a highly efficient steel wire coil wrapping machine that comes with loading/unloading trolley equipment. It is specifically designed for packaging ...

The FPW-600 is a steel wire coil wrapping machine featuring a trolley for easy coil loading and unloading. Primarily used for packaging big prestressed concrete w...

FPW-500 series wire coil wrapping machine has trolley attached for loading and unloading. The electric components: Siemens PLC provides incomparable control of co...

The FPW series wire coil wrapping machine is specifically designed for packaging steel wire coils, copper coils, and other similar products. This highly efficient...

The FPW-300 is a wire coil ring wrapper intended for medium-sized coils. It is capable of wrapping coils with various packaging materials, such as LLDPE stretch f...

All of the machines provided by Fhope conform to CE guidelines and are designed using the latest technology and design criteria for industrial use. Fhope offers a...

This steel wire packing machine can wrap coils with paper and plastic film simultaneously. Its wrapping station can move up and down for safe and easy loading/unl...

The automatic winding machine, also known as a winder, is a device designed for wrapping various materials such as string, twine, cord, thread, yarn, rope, wire, ...

The strapping machine dispenses, tightens and seals polypropylene while coil in strapping position. The machine strap and joins the ends automatically with adjus...

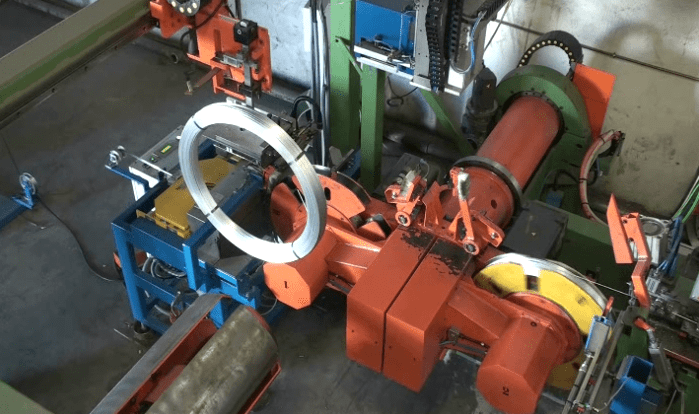

The automated steel wire coil packaging solutions designed for fullfill the automatic packing after the steel wire drawing. Driven by a commitment to innovation, ...

For Steel Wire Winding, Packing and stacking online. Different solution for special wire rewinding, JUST CONTACT US....

FPC Copper coil wrapper FPC400 FPC series copper coil wrapper is mainly used to copper packaging. It also named copper wire wrapping machinery, copper coil pack...

The FPC-300 copper coil wrapper is the ideal horizontal type packing solution for businesses in the copper industry. With easy operation, excellent product protec...

The FPC-200 is a specialized machine designed for packing copper coils, with a width range of 20mm-200mm. It is also referred to by other names, such as the coppe...

The copper tube coil packing machine is a versatile equipment suitable for wrapping various types of coils externally, including steel or copper, pipe or wire. Th...

The copper coil packing line is an integrated system that automates the copper coil processing from the copper coil slitting line to the packaging and storage sys...

FPH series coil wrapper is the latest model mainly for hose coil, PEX pipe,PE pipe, corrugated pipe, HDPE plastic pipe packaging. This machine saves labor and mat...

FPH series hose coil wrapper is the machine designed mainly for hose coil, plastic packaging. Efficiency and convenient operation save labor and packaging mater...

The pipe wrapping station features a rotating ring that is reinforced with a solid cast aluminum construction for durability. The driving wheels are made of polyu...

The pipe bundle packing solution is an efficient and automated system designed for plastic pipe factories. It features automatic counting of the number of pipes a...

The bag packing machine for plastic pipes and pipe bundles is designed to work with various types of pipes, including PPR, PVC, PE pipes, and more. This machine i...

The FPCW series cable packaging machine is designed for efficient and visually appealing packaging of cable coils and other materials, offering the advantages of ...

Fhope now offers a specially designed cable coil wrapping machine for cable ID: 90mm only, capable of high-speed coil eye through-wrapping for improved packaging ...

The cable coil wrapping machine is a highly efficient and visually appealing packaging solution. It features an easy-to-maintain design that facilitates quick and...

The FPCA-300 is a specialized machine designed for wrapping big-sized cable coils. The machine features packing material and relative devices specifically designe...

The cable coiling machine is a highly advanced system capable of automatic cable length calculation, coiling, and cutting. With the option to add a wrapping or st...

This packing line is specifically designed for cable coil packaging, providing an efficient and cost-effective solution that minimizes labor costs and saves time....

The automatic cable strapping machine is a high-speed solution designed for cable coiling and banding, with a speed of up to 60 pieces per hour. It boasts a high ...

The cable winding and strapping solution is an efficient system designed for wire cables, electric cables, cable shrinking, and strapping. With a speed of up to 2...

The Automatic Cable Winding and Packing Machine enhances cable handling with precise winding and packaging in a single, automated process. Suitable for different ...

The Automatic Cable Wire Winding and Packing Line optimizes cable handling by automating key steps like winding, bundling, and packaging. It increases production ...

The Cable Coil Shrinking Machine is designed for shrink-wrapping cable coils, hoses, and pipes. It features a high-efficiency heating system and a durable conveyo...

This bearing wrapping machine is specifically designed to meet the packaging needs of large-sized bearings and axletrees. With its high efficiency, the machine ca...

This machine is designed to provide a reliable and efficient packaging solution for bearings. It is an online and automatic system that can be customized to meet ...

The primary purpose of this bearing wrapping machine is to wrap large-sized bearings and axletrees. Its key benefits include improving packaging quality and speed...

This machine is designed to provide a reliable and efficient packaging solution for bearings. It is an online and automatic system that can be customized to meet ...

FHOPE offers a packaging solution for big-sized bearings used in various applications such as supportive, wind, turbine, blade, and slewing ring bearings. This ma...

The small bearing bagging machine is a specialized piece of equipment designed to package small bearings efficiently and effectively. It can seal up to 60 bags p...

A bearing wrapping machine is a specialized piece of equipment used in industrial settings to wrap bearings in protective materials. The machine is designed to ef...

The Stainless Aluminum Master steel Coil Packing Machine and Stretch Wrapper is a state-of-the-art packaging solution designed to streamline the process of packin...

The FPA-400 is an automatic machine that protects aluminum coils during shipping. It can wrap coils up to 400mm wide and 500kg and uses a cutting system to reduce...

The Aluminum Coil Paper Packing Machine with Trolley is an advanced and efficient solution for wrapping aluminum coils. Its features include an adjustable wrappin...

The motorcycle tyre packaging machine is specifically designed for lightweight tyres, effectively preventing them from shaking during the packaging process. By a...

The tyre packing machine is a highly effective solution for achieving high-quality packing of tyres and improving their overall appearance. Its easy-to-use design...

The automatic packaging machine for large tires and rolls is a revolutionary solution that eliminates the need for manual tyre packaging. The machine features a f...

The automatic tyre packing line is a cutting-edge automation system consisting of a horizontal tyre wrapping machine, information reading and sending modules, and...

The horizontal stretch wrapper is a specialized machine used for the online handling and packing of tyres. Its primary function is to wrap one or more tyres toget...

Established Expertise: With 15 years of experience, FHOPE has a proven track record in the coil packing industry.

Dedicated Team: Over 20 engineers are dedicated to innovating and improving our machines, ensuring top-tier quality and performance.

Global Presence: FHOPE machines are in operation worldwide, with over 10,000 units installed across different continents.

Spacious Facilities: Our 3000 square meter production factory allows for high-capacity manufacturing and rigorous testing of each machine.

Advanced Technology: We offer automated packing systems that streamline your operations, reduce labor costs, and increase efficiency.

In coil packaging solutions, choosing the right orientation is essential for ensuring efficiency and safety during transport and storage. The packaging industry primarily uses two coil orientations: vertical and horizontal. Each orientation serves different types of coils, meets specific wrapping needs, and fits various material handling situations. Knowing the differences and advantages of each orientation helps businesses choose the best method. This improves their packaging processes and keeps their products safe.

The horizontal orientation features the coil's inner diameter (ID) facing upwards during the wrapping process. This method is particularly well-suited for automatic coil packing machines, coil packing lines, and special coils, such as copper and hoses. Horizontal wrapping offers several advantages, including improved packaging for irregularly shaped coils, lightweight coils, and coils with small IDs. This orientation is also beneficial when dealing with delicate or sensitive materials that require extra care during the packaging process. By providing a more uniform wrapping and enhanced support for the coil, the horizontal method can lead to better product protection and safer handling throughout transportation and storage.

Various coil packing materials are available to suit the diverse needs of different coil packages and companies, ensuring adequate protection and optimized performance during transportation and storage. The choice of packaging material plays a significant role in determining the overall durability, appearance, and cost-effectiveness of the packaging process. Here are some typical packing materials for coil packaging, along with their unique features and applications:

Stretch film, commonly made from low-density polyethylene (LLDPE), is a versatile and cost-effective material that provides a sealed packaging for coils. With good tension control and sufficient overlap, it can offer excellent water and moisture resistance, making it a popular choice for various industries. Stretch film is also easy to apply and remove, contributing to a more streamlined packaging process.

The strength of the paper is weak, so the original paper cannot be used for coil wrapping. But after reinforcement treatment with PP belts, PE film covering, the paper works for steel coil, wire coil, copper coil...packaging. After packaging with paper, the surface of the package is wear-resistant. Also, the paper provides the VCI formula that is for moisture-proof packaging for seaworthy packages or rainy season packages.

High-density polyethylene (HDPE) or polyethylene (PE) films are non-adhesive materials with a thickness of more than 50 microns. These films provide effective protection against scraping, ensuring that the packaged coil's surface remains damage-free during handling and transportation.

Woven knit belts are typically made from polypropylene (PP) and are flexible yet stronger than paper and film. Their durability makes them popular for packaging razor wire, steel coil, and wire coil products. Woven knit belts protect coils from scrapes during transportation and can be customized to accommodate various coil sizes and shapes.

The ring is one of the most important parts of the coil packing machine. The packing material is fixed/stored on the ring for eye through wrapping. The ring size varies from the package size. If the package size range is large, for compatibility, the ring will be designed for the largest coil, which works for smaller coils. The ring rotates at high speed, so the ring material and structure design is very important to ensure it runs for a long time.

It is important to choose the proper coil packing machine. The machine version needs to be designed to fit the handling methods used in your factory. There are various handling methods depending on the coil weight and size, such as manual loading for light products, conveyor loading for connecting with the production line, crane loading for heavy products, and forklift for coil moving...

The packaging reduces corrosion, water spots, dust, and rust, protecting the coil's surface during storage and transport. Explore our full range of coil packaging options, including sizes, speeds, and materials, and find the perfect solution for your needs.

Choose by product, like wire coil wrappers or hose wrapping machines, or by industry to meet your specific packaging requirements. Fhope offers comprehensive coil packing solutions for any size, from small ID coils to heavy, large ones, handling up to 35T coils. Local services including installation, commissioning, and training are available.

For specific needs, Fhope provides customized solutions, from semi-automatic to fully automatic systems that include coiling, wrapping, strapping, handling, and stacking to meet your packaging goals.

FPS-200-400 open up FPS-200-400 open up

|

PS-200-500 open down PS-200-500 open down

|

FPS-300-500 Vertical FPS-300-500 Vertical

|

FPCA Series FPCA Series

|

The coil wrapping machine is a specialized piece of equipment designed for wrapping various coil-shaped products with different types of packing materials. That is a kind of eye through ring wrapper. It provides secure and efficient packaging for a range of industries. MORE INFO

The machine provided by FHOPE can accommodate various packing materials, including stretch film, paper, PP knit belts, PVC film, and HDPE film. FHOPE providing customzied solution per different packing material if your packing material not in above range.

Yes, the machine designed by our team allows to handle various coil sizes and dimensions, offering flexibility for different applications and industries. FHOPEGROUP had provided coil packing solution from Min. coil OD:60mm to Max.Coil OD:6500mm. Our team will help to do semulation and provide the best solution per your coil packaging.

The life expectancy of a coil stretch wrapping machine varies depending on factors like usage, maintenance, and quality of the components. Proper care and regular maintenance can significantly extend the machine's lifespan upto 15+ years.

Consider factors like coil dimensions, packing material, required wrapping speed, and budget when choosing the right coil wrapping solution. Consult with our team to ensure the machine meets your specific needs.

The cost of packing materials for one coil wrap depends on following points: 1. the type and quantity of the material used; 2. the coil size in OD x ID xWidth; 3. overlapping rate. Consult with the manufacturer or supplier for accurate cost estimates.

If the machine encounters a problem,checking the manual and trouble shooting list firt. making a recorder by photos&videos that shows the problem and contact our service team for technical support and troubleshooting assistance. Most machine equipts the remote control moudle, our team will help to check the machien status asap online. In some cases, on-site support or replacement parts may be necessary.

Yes, it is advisable to keep essential spare parts on hand to minimize downtime. Consult with the manufacturer for a list of recommended spare parts.

Loading the coil, start the machine: The coil will be wrapped by the chosen packing material around the coil-shaped product through an eye-like structure. The length of the packing material will be cuculation by PLC. And it will be automatic cutting by cutter. More information for coil packing steps:

Usually, the simple training is ok. The machine designed for easy operation.It was designed in fool style operating machine for non skiled worker. Simple training and user manuals are typically provided to ensure a smooth experience. Most machine packing and delivery without dismentling, only depacking and power connecting required to running the machine.

Regular maintenance and cleaning, as per the manufacturer's guidelines, are crucial for optimal performance and longevity. This may include inspecting, lubricating, and cleaning various components. MORE INFO FOR MAINTENANCE

After-sales support and warranty terms vary among manufacturers. Ensure to inquire about these details before purchasing the machine. After service for coil wrapping machine

Yes, we offer custom-made coil wrapping machinery that matches to specific requirements. Consult with the manufacturer to discuss your needs and explore available options.

The cost of the machine depends on factors like features, coil size, Max.loading, speed capabilities, and customization. Contact with our team for a detailed quote based on your requirements. Price list reference

Delivery and installation times vary depending on factors like the machine's complexity, location, and availability. Standard machine takes app. 30-45days. please contact with our team for accurate timelines.

Yes, the main part of the machine such as motor, PLC, inverter, bearing...are international standard. So you can find the replacement from your country. Sure you can buy from us too.

1: Improved packaging efficiencyby quickly and accurately coil packing.This reduces packaging time and increases productivity. One coil wrapping time app. 20-50 sec per coil size.

2: Reduced labor costsThe machines minimize the need for manual labor in the packaging process.This can help to reduce labor costs. one machine replace 3-5 people

3: Increased product protectionWrapping coils tightly and securely helps prevent damage during shipping and handling.

4: Enhanced product appearanceA The wrapping machine can help to enhance the appearance of the product.This can make it more attractive to customers.

As a manufacturers we can provide UL and CE certification upon request, which validate the machine's compliance with relevant safety. CE report for coil wrapping machine

1. Real coil wrapping machine manufacturer with 100+ show case.

2. Top automatic coil packing line manufacturer in China

3. How To Do Good Packing Tension Control for small Coil Packing by big machine

4. How to choose the packing material width for coil eye through packing

5. PACKAGING FOR A COIL OF STEEL STRIP

6. Coil packing line equipped with independently reciprocating carriages

Our team will reply in 24 hours

![]() Email: info@fhopepack.com

Email: info@fhopepack.com

![]() Whatsapp: 0086-13951501635

Whatsapp: 0086-13951501635

I'm online now.