Click to Chat

I'm online now.

Fhopepack Innovation

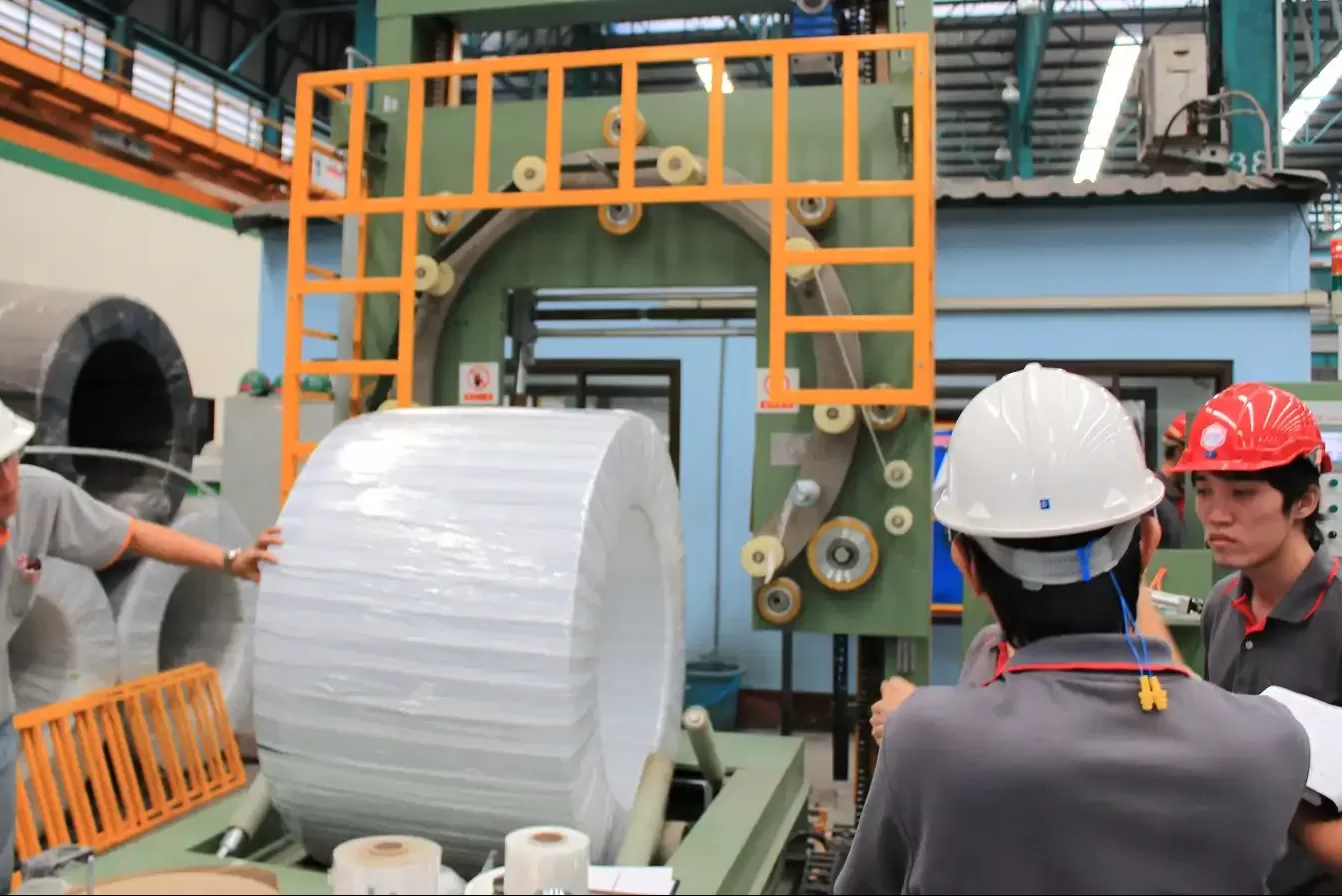

This coil wrapping machine is tailored for steel wire coils, offering precise and durable packaging to protect coils from environmental damage and handling wear. Its adjustable wrapping settings accommodate various coil sizes, enhancing efficiency and ensuring a neat, reliable wrap suitable for industrial packaging standards.

Coil wrapping machine for steel wire coil are essential for securely packaging steel wire coils, protecting them from damage and ensuring safe transport. Various types of coil wrapping machines are designed to meet specific industrial needs based on coil size, handling requirements, and automation level. Below are the main types, each offering distinct benefits:

Automatic coil wrapping machines are fully automated solutions that handle all steps in the wrapping process, including feeding, centering, wrapping, and material application. These machines are ideal for high-volume facilities as they reduce manual labor, improve speed, and maintain consistency. The automation includes automatic in-feed and out-feed systems, ensuring precise coil placement and smooth handling. They are particularly advantageous for large-scale operations where speed and efficiency are crucial.

Semi-automatic machines offer automated wrapping while requiring manual setup for material feeding and cutting. They are well-suited for small to medium-sized operations where flexibility is necessary, but full automation isn’t essential. Operators manually feed the packing material and adjust for coil placement, while the machine automates the wrapping process, including “eye through” packing—where the wrapping is applied through the coil’s central opening. This type is beneficial for facilities that handle smaller batches or require more control over each wrap cycle.

Horizontal steel wire wrapping machines are designed with a horizontally aligned wrapping station that can either be fixed or movable, depending on the coil size. For large-diameter coils, the wrapping station moves to accommodate the coil, making it ideal for heavy-duty applications and large coils. For smaller coils, a stationary wrapping station allows the machine to wrap efficiently without requiring movement, making it space-efficient and suitable for lighter-duty operations. This flexibility makes horizontal wrapping machines popular in steel and cable industries where coil sizes vary significantly.

Vertical wrapping machines are optimized for compact, smaller coils and are often manually loaded and unloaded, either by hand or using a crane. This type is ideal for operations that handle smaller coils from the side, where precise positioning is needed. Vertical machines are compact and generally easy to install, making them a good choice for facilities with limited floor space. The manual loading aspect allows operators to position coils carefully, ensuring secure wrapping without damaging the material.

Selecting the appropriate coil wrapping machine is essential for efficient and safe coil packaging. Factors such as coil dimensions, production volume, and facility layout play a crucial role in determining the ideal machine type. Automatic and semi-automatic options cater to different production demands, while horizontal and vertical orientations provide versatility for specific coil handling and wrapping needs. With the right machine, facilities can enhance productivity, reduce damage, and improve packaging consistency.

|

Model |

Voltage (V/Hz) |

Power (KW) |

Coil ID (mm) |

Coil OD (mm) |

Coil Width (mm) |

Coil Weight (Kg) |

Packing Material |

|

|

FPW-300 |

customized

|

1.5 |

508-610 |

600-1200 |

100-300 |

20-1000 |

PVC/LLDPE/PE/PAPER/HDPE |

|

|

FPS-400 |

customized |

4.0 |

508-610 |

800-1400 |

100-400 |

100-2000 |

PVC/LLDPE/PE/PAPER/HDPE |

|

|

FPS-500 |

customizable |

2.0 |

508-610 |

700-1400 |

200-500 |

100-1000 |

PVC/LLDPE/PE/PAPER/HDPE |

|

|

FPS-600 |

customizable |

7.5 |

700-1100 |

1000-1500 |

200-600 |

200-2000 |

Crepe paper/plastic knit tape |

|

|

FPS-800 |

customizable |

7.5 |

508 |

800-1400 |

400-800 |

200-1000 |

PVC/LLDPE/PE/PAPER/HDPE |

|

|

FPCA-1000 |

customizable |

4.5 |

508-610 |

700-1600 |

20-400 |

100-2000 |

PVC/LLDPE/PE/PAPER/HDPE |

|

Coil wrapping machines are critical assets in industries that handle steel wire, ensuring coils are securely packaged and protected from environmental and physical damage. With growing demands in sectors like construction, manufacturing, and transportation, coil wrapping machines play a pivotal role in enhancing productivity and ensuring product quality. This guide explores how coil wrapping machines function, their benefits, and key considerations for industries relying on steel wire coils.

Wrapping steel wire coils is essential for maintaining the integrity and usability of the steel, preventing damage from moisture, dust, and physical impact. Unlike other materials, steel wire requires extra protection due to its weight and potential corrosion when exposed. Wrapping machines designed for steel wire offer robust solutions that cater to these needs, making them indispensable in industrial packaging.

Coil wrapping machines streamline packaging by automating the process, which minimizes labor, reduces handling time, and enhances the overall efficiency of steel manufacturing and shipping operations. Moreover, proper wrapping provides vital protection during transit, storage, and handling, ensuring coils arrive at their destination in optimal condition. This helps avoid costly losses and protects the company's reputation by delivering quality products consistently.

Each coil wrapping machine is built with several critical components, each tailored to serve a specific function:

Customization options, such as adjustable turntables and adaptable dispensers, allow the machine to accommodate various coil sizes and shapes, making them versatile for different industrial needs.

| Feature | Automatic Machines | Semi-Automatic Machines | Horizontal Wire Wrapping Machines | Vertical Coil Wrapping Machines |

|---|---|---|---|---|

| Primary Characteristic | Fully automated operation. | Manual setup with automated wrapping. | Coil axis is horizontal during wrapping. | Coil axis is vertical during wrapping. |

| Level of Automation | Highest; minimal human intervention. | Medium; requires operator for loading/unloading & setup. | Can range from semi-automatic to fully automatic. | Can range from semi-automatic to fully automatic. |

| Human Intervention | Minimal (e.g., monitoring, material replenishment). | Significant (e.g., coil loading, cycle initiation). | Varies with automation level; can be low to significant. | Varies with automation level; can be low to significant. |

| Ideal Coil Dimensions | Suitable for a wide range, often for consistent sizes in high throughput. | Best for varied or smaller batches; adaptable to different sizes with manual adjustment. | Ideal for large-diameter, wide, or heavy coils. Often unstable coils that need support. | Suited for compact, smaller diameter coils. Can handle narrower coils effectively. |

| Production Volume | High; continuous operation. | Low to medium; batch operations. | Medium to high, especially for large or specialized coils. | Low to medium; suitable for specific coil types. |

| Coil Handling | Typically integrated with automated loading/unloading systems. | Manual or assisted loading/unloading. | Coils are usually fed horizontally, supported by conveyors or rollers. Eye of the coil is typically perpendicular to the direction of travel. | Coils are often placed on a turntable or moved with the eye facing upwards or sideways (towards a wall). |

| Efficiency | Maximizes efficiency and throughput. | Offers improved efficiency over manual methods for smaller operations. | Efficient for specific coil types (large/heavy); throughput depends on automation. | Efficient for specific coil types (compact/smaller); throughput depends on automation. |

| Flexibility | Can be programmed for various wrap patterns and coil sizes, but typically optimized for specific ranges in a line. | More flexible for varying coil sizes and types due to manual setup. | Good for a range of large coils; some models offer high adjustability. | Good for specific ranges of smaller coils; adjustability varies. |

| Footprint | Can be large, especially with integrated conveyor systems. | Generally more compact than fully automatic systems. | Can be substantial to accommodate large coils and conveying systems. | Often more compact than horizontal machines for similar capacity. |

| Key Advantages |

- Highest throughput - Reduced labor costs - Consistent wrapping quality - Enhanced safety |

- Lower initial investment - Simpler to operate and maintain for basic needs - Good for lower volume or varied production |

- Best stability for large/heavy/unstable coils - Prevents telescoping of wide coils - Integrates well with horizontal production lines |

- Space-efficient for certain layouts - Effective for smaller, stable coils - Can provide tight, secure wrapping |

| Typical Applications | High-volume steel wire production lines, large manufacturing plants. | Smaller workshops, job shops, operations with diverse or infrequent wrapping needs. | Steel mills (e.g., wire rod, slit coils), large cable manufacturing, heavy-duty coil packaging. | Wire drawing facilities, manufacturers of smaller wire products, hose or tube coils. |

| Handling Requirements of Facility | Requires robust infeed/outfeed systems (conveyors, cranes). Facility layout should support automated flow. | Manual or semi-automated handling (e.g., forklifts, hoists). Less demanding on facility integration. | Requires infrastructure for handling large/heavy coils (e.g., C-hooks, heavy-duty conveyors, overhead cranes). | Coil handling can range from manual to automated tilters and conveyors, depending on the machine's level of automation. |

Note: The "best" machine depends heavily on the specific application, including the type and size of steel wire coils, required production speed, level of automation desired, available budget, and facility layout.

A coil wrapping machine typically operates by placing the steel coil onto a turntable, where it is rotated as the wrapping material is applied. The operator, or automated control, initiates the wrapping process, and the machine applies the chosen film or material with uniform tension to avoid wrinkles or loose sections. Safety mechanisms, such as emergency stops and protective guards, ensure that operators are protected from any unexpected mishaps during operation.

The use of coil wrapping machines offers a multitude of benefits:

Companies investing in these machines witness significant improvements in both operational efficiency and product quality, reinforcing the value of this technology in competitive markets.

Below are key factors to evaluate in order to make an informed decision:

Coil Size and Weight: It’s vital to choose a machine that accommodates the dimensions and weight of the coils your operation handles. Different machines have varying capacities, and selecting one that meets your specifications will prevent potential operational issues and maintain wrapping quality.

Automation Level: Facilities with high production demands may benefit from fully automated coil wrapping machines, which streamline processes and reduce labor requirements. In contrast, smaller operations with lower throughput may find semi-automated machines more cost-effective, providing flexibility and control without excessive upfront investment.

Material Compatibility: The selected machine must be compatible with the necessary wrapping materials. For steel wire coils, durable materials like stretch film or protective wraps are often essential to prevent corrosion and mechanical damage. Ensuring material compatibility prevents material waste and maximizes protective coverage for each coil.

Automation in coil wrapping machines allows for faster, more consistent wrapping with minimal human oversight. Automated machines are equipped with programmable settings, allowing companies to set parameters such as wrap tension, material type, and coil size for consistent results across large batches. This reduces human error, speeds up production, and allows for accurate, uniform wrapping on every coil, thus greatly improving overall productivity and reducing waste.

There are several leading manufacturers known for high-quality, reliable coil wrapping machines. Brands like FHOPEPACK, ROMM, Signode, and SHJLPACK offer machines with varying features tailored for steel wire coils, ranging from compact, semi-automatic models to fully automated systems with advanced sensors and programmable controls. Each model presents its own set of advantages and considerations based on machine footprint, energy consumption, and level of automation.

How does a coil wrapping machine differ for steel vs. other materials?

What materials are used for wrapping steel wire coils?

Can coil wrapping machines handle different coil sizes?

Are coil wrapping machines suitable for other types of metals?

How can companies ensure safe operation of these machines?

I'm online now.