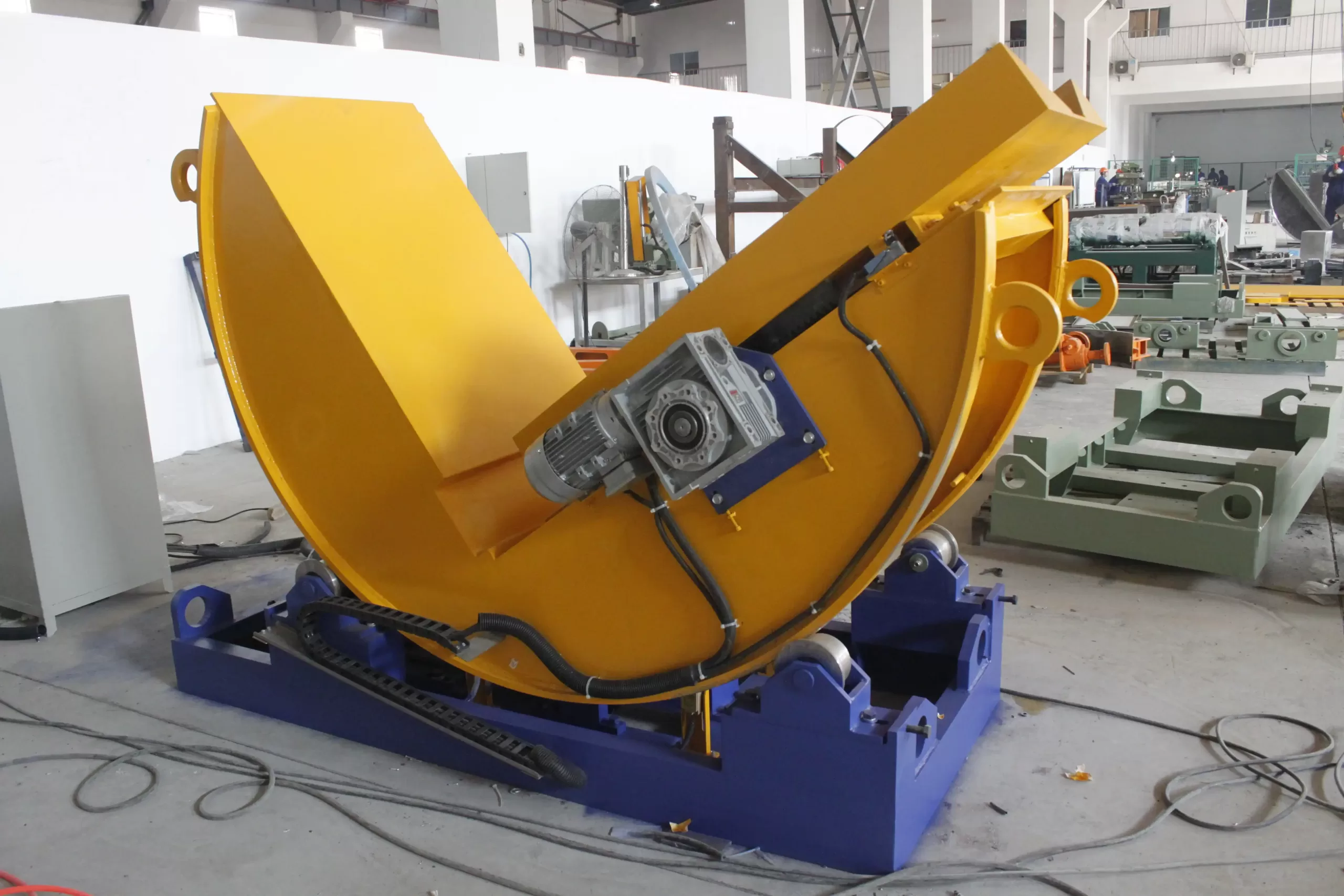

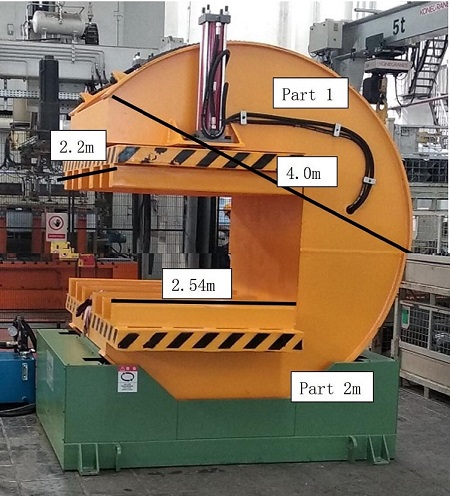

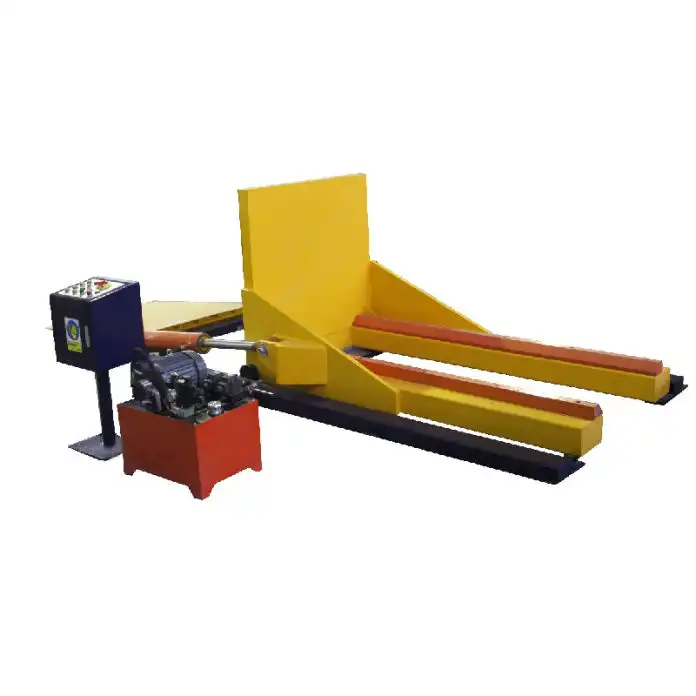

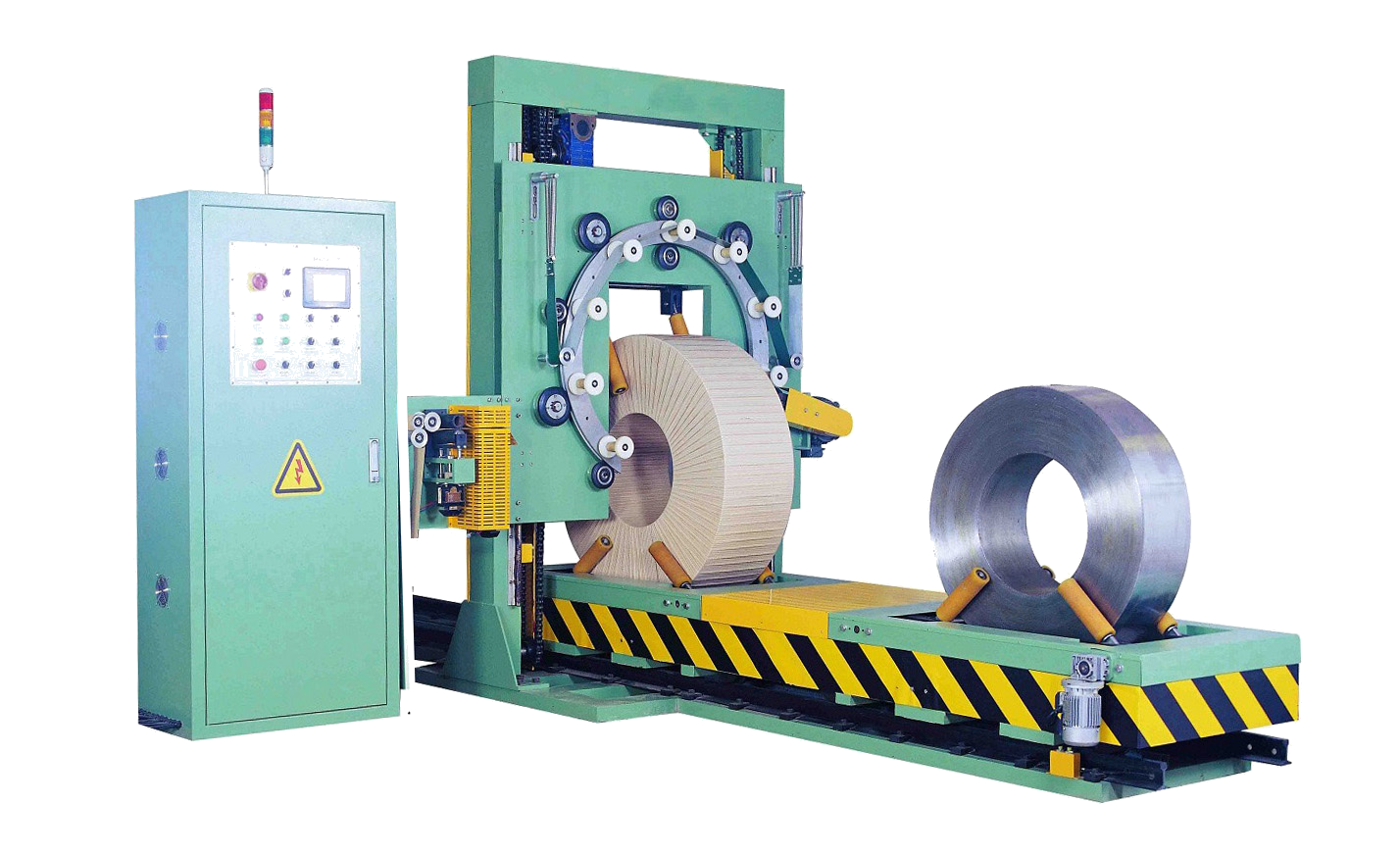

Upenders

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Movable Coil Upender Tilter, Hydraulic Upender Manufacturers

-

-

-

-

-

Manual vs. Automatic Coil Upenders: Which Offers Better ROI?

-

Evaluating Steel Coil Upenders Based on Load Capacity and Eff

-

-

How Coil tipper Provide Reliable Long-Term Performance: What

-

The Importance of Load Stability in Coil Upenders: Technical

-

-

-

-

Worker Fatigue and Safety: The Need for Automated Coil Turnin

-

How Coil Upenders Mitigate the Risk of Coil Damage During Tra

-

Weight Capacity and Speed: Understanding Coil Upender Perform

-

-

Maintenance Requirements for Coil Upenders: What You Need to

-

-

-

-

-

-

-

-

Hydraulic Upender for Steel Sheet Loading and Pallet Changing

-

Comprehensive Guide to Upenders and Coil Tippers Features, De

-

-

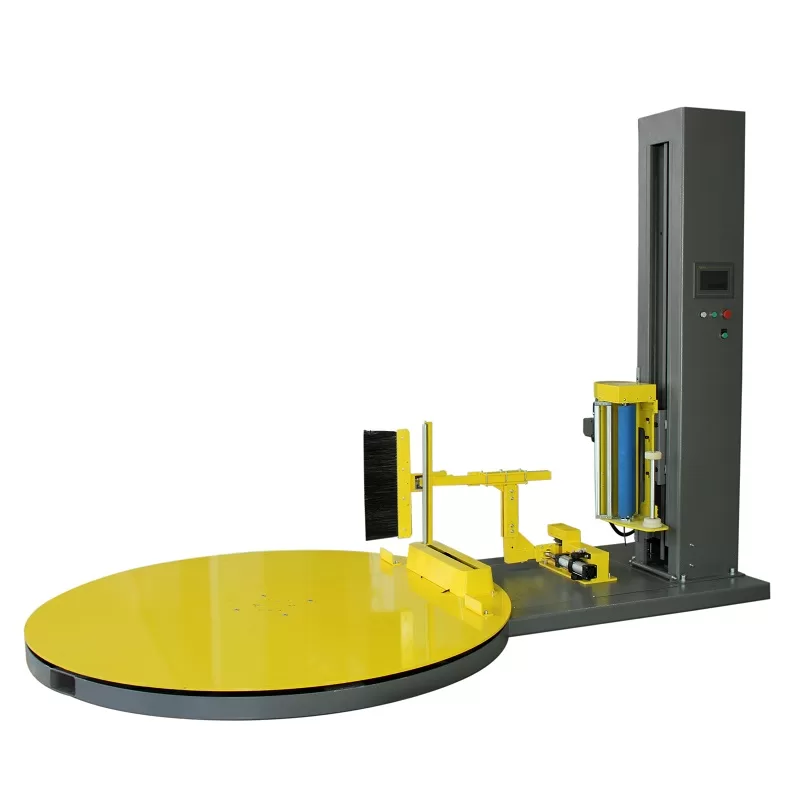

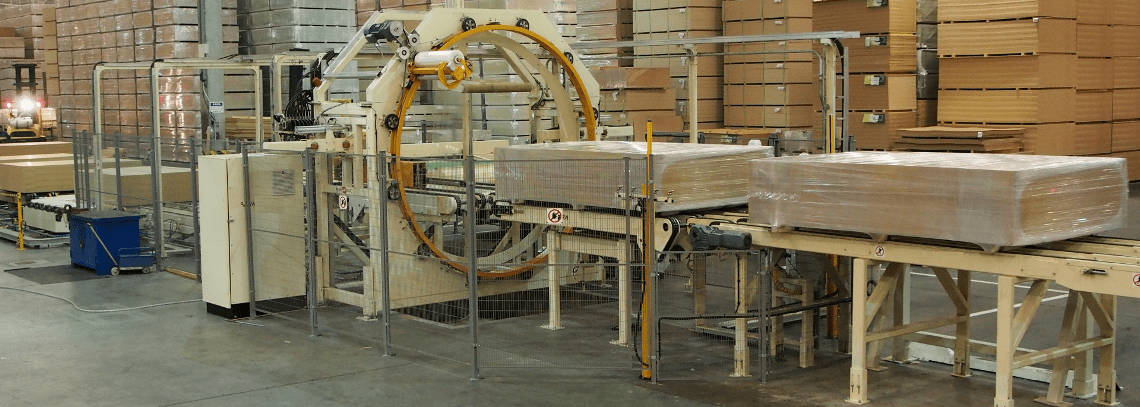

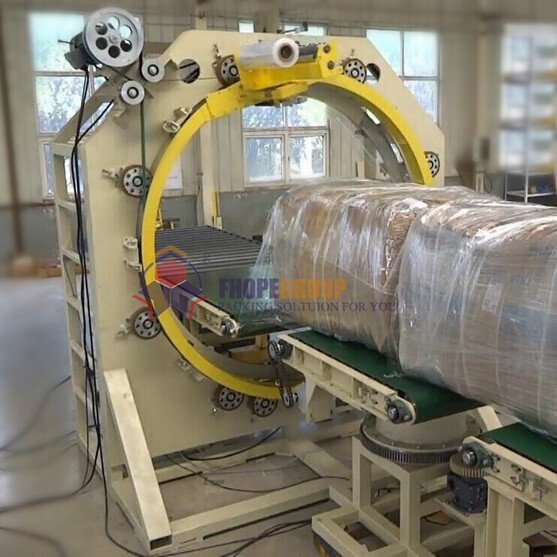

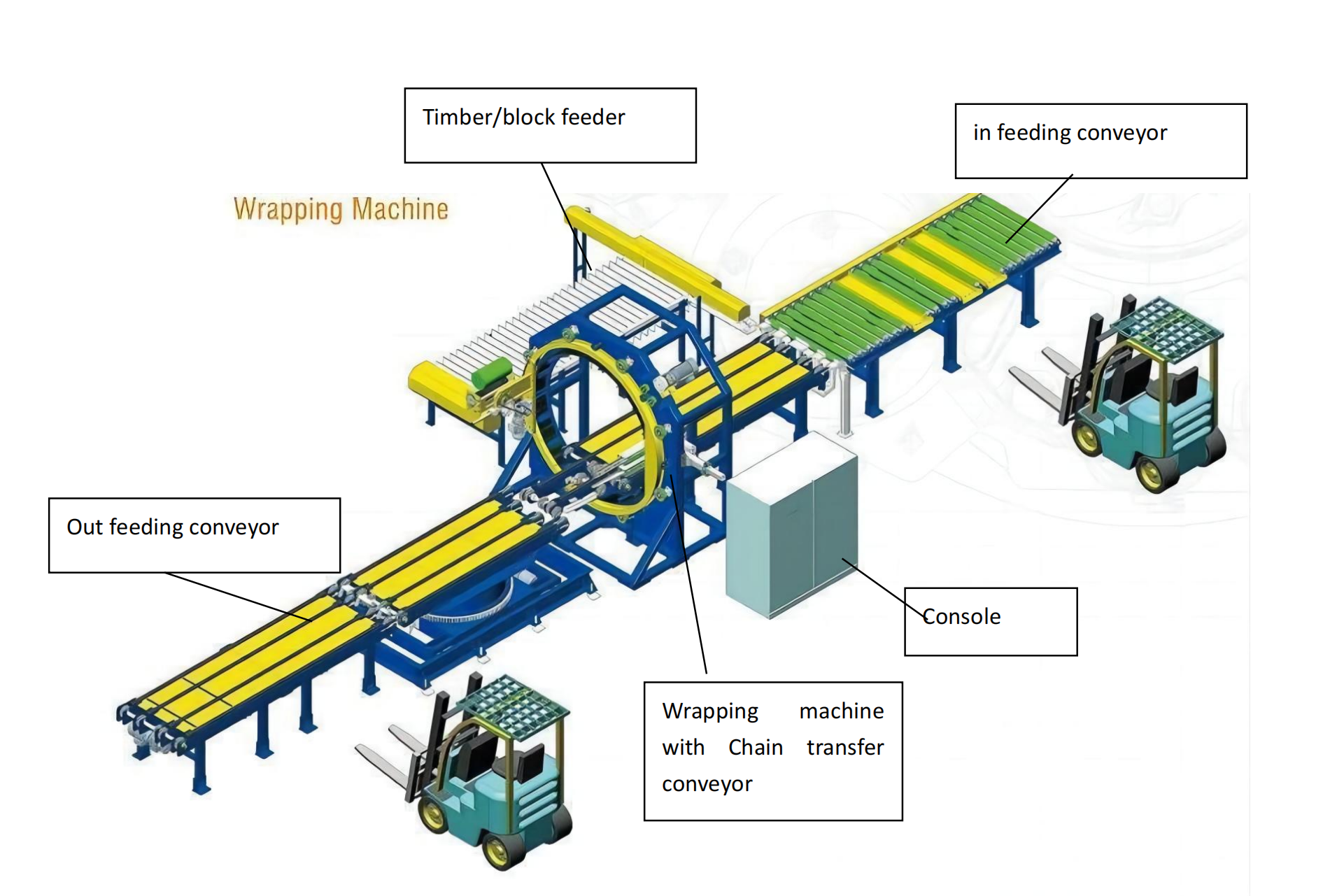

Orbital Stretch Wrapper

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Evaluating Solutions: Comparing Horizontal Wrapping Systems f

-

Implementation and Delivery: Effective Setup of a Horizontal

-

Horizontal Stretch Film Wrapper: Recognizing Packaging Challe

-

Market Analysis: Finding the Best Orbital Packaging Machine f

-

Solution Evaluation: Comparing Horizontal Rotary Wrapping Mac

-

Internal Decision Criteria for Selecting Horizontal Pallet Wr

-

Automation Levels in Six-Sided Horizontal Orbital Stretch Wra

-

Evaluating the ROI of Upgrading Your Six-Sided Horizontal Orb

-

Negotiation Tactics: Securing the Best Ring Wrapping Machine

-

Spiral Stretch Wrapper for Efficient Product Handling: Implem

-

Rotational Stretch Wrapping Machine: Demand Identification fo

-

Horizontal Cargo Wrapping Machine: Market Analysis for Effect

-

Horizontal Bundling Machine for Product Safety: Solution Eval

-

Supplier Selection Guide: Ring Orbital Wrapping Machine for C

-

Internal Decision Guide for Choosing Horizontal Shrink Wrap M

-

Negotiation Strategies for Horizontal Ring Wrapper for Bulk M

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Pallet Exchanger

Wooden & board packing solution

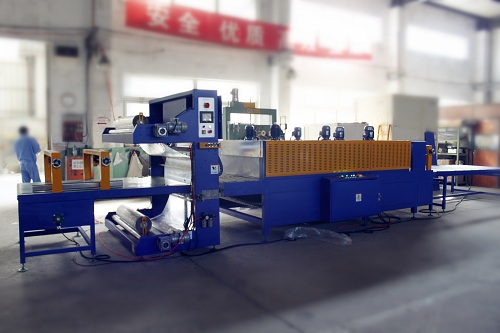

Door Packing Machine

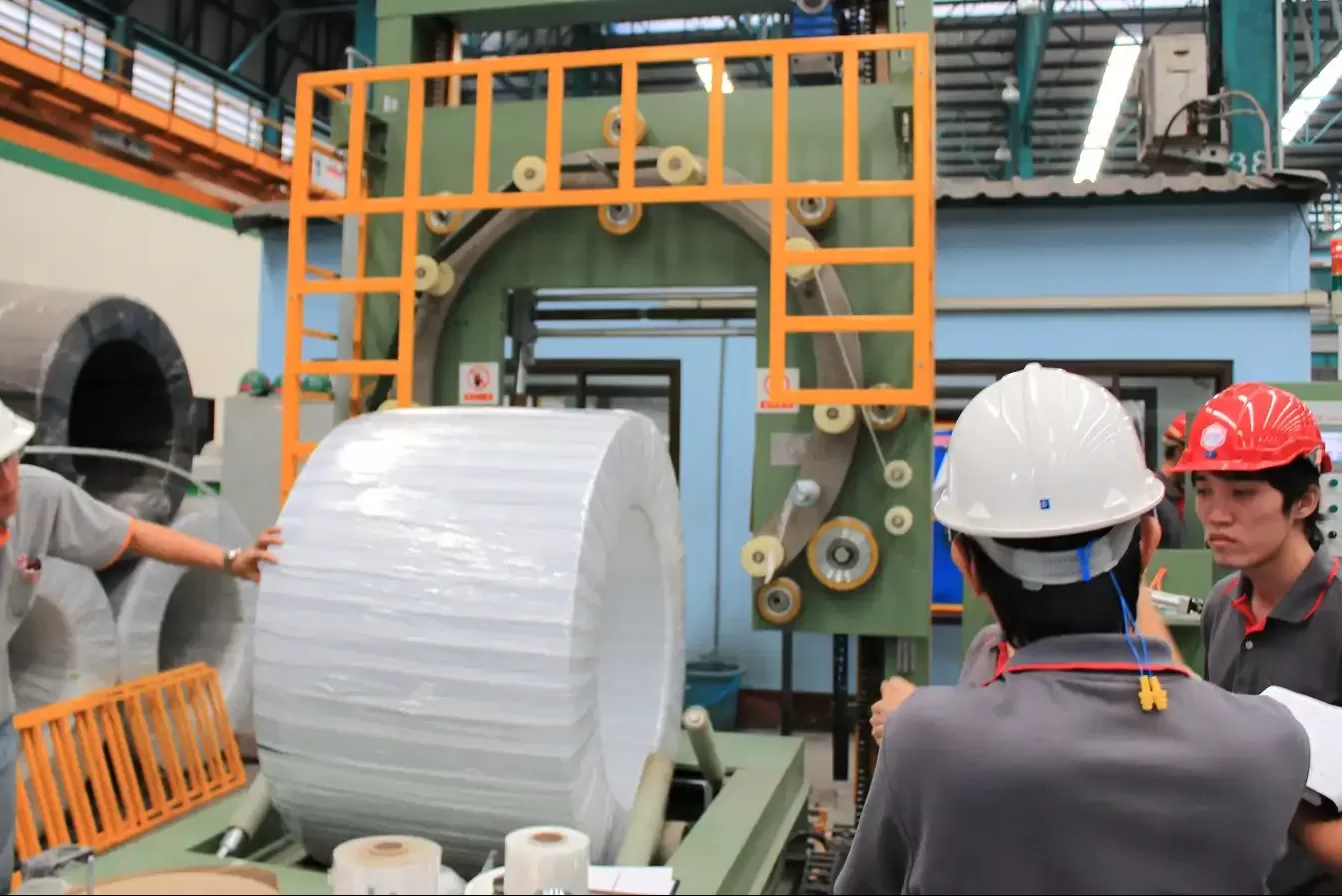

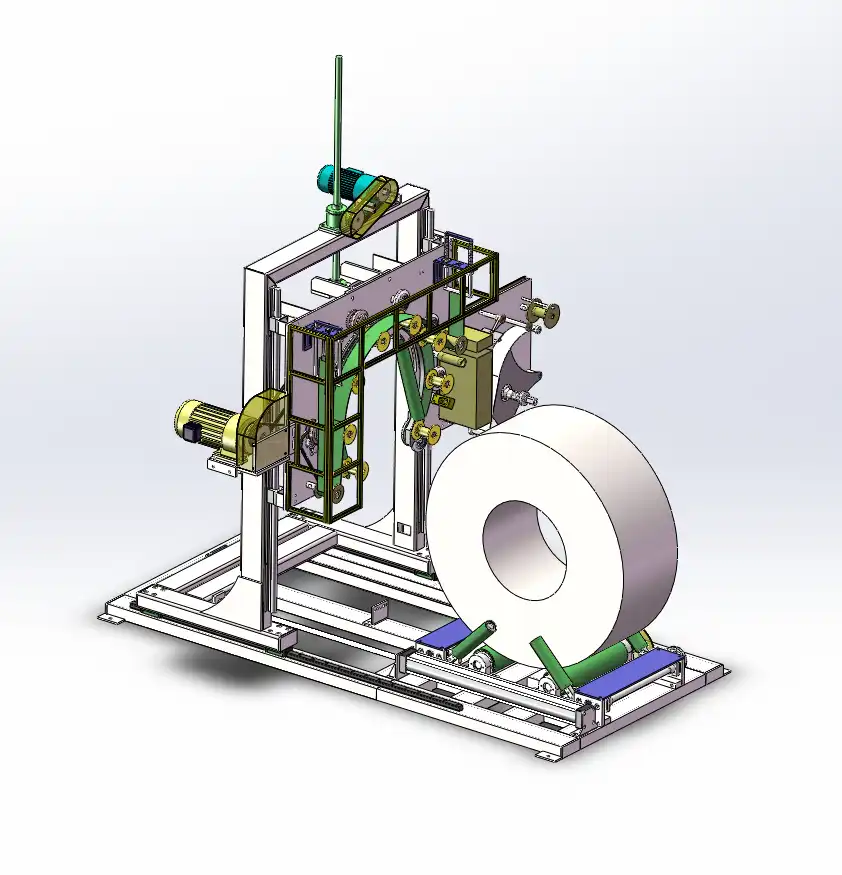

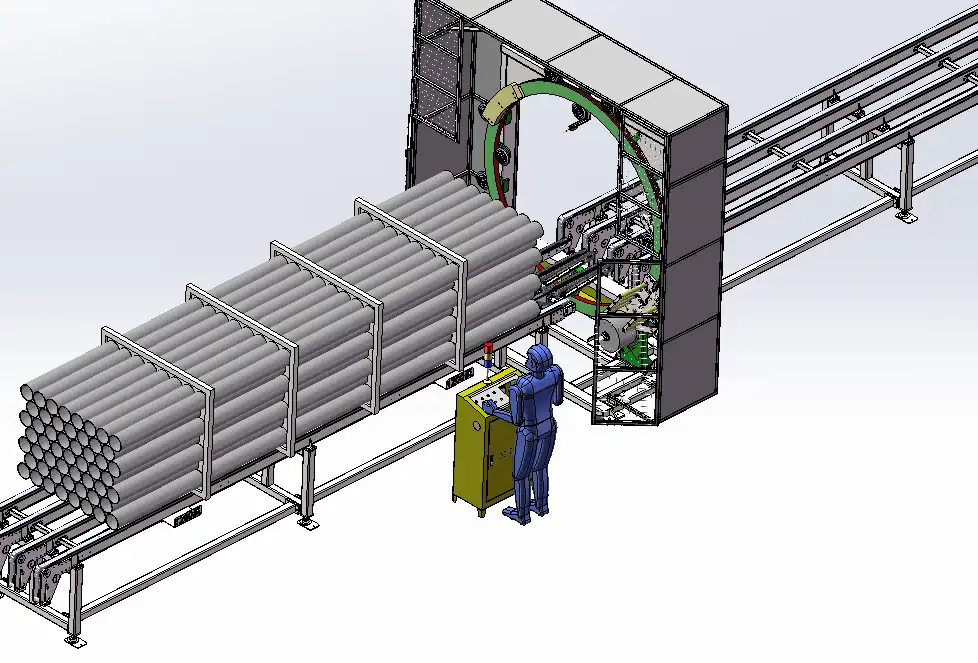

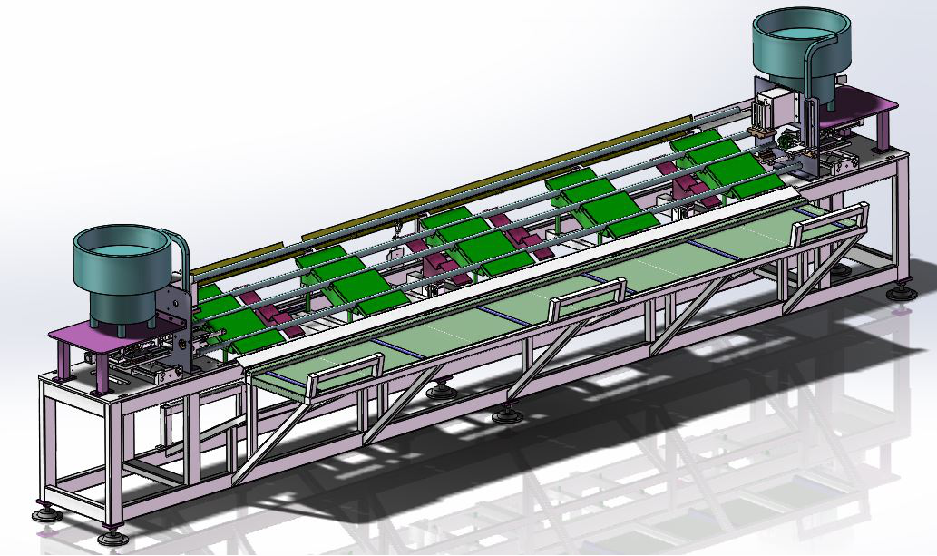

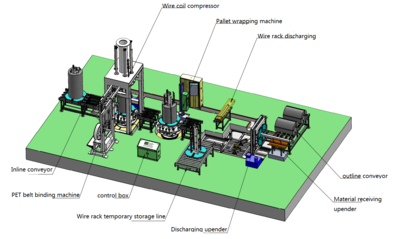

Coil Packing Line

-

-

-

-

What Is The Technical The Best Coil Packing Line Should Inclu

-

-

What after service you will have for Copper strip packing lin

-

What Is The Technical Efficiency for Slit Coil Packaging Syst

-

How to measure the technical efficiency for steel coil strapp

-

Guide to Optimizing Operational Expenditures For Steel Coil S

-

Solutions for Optimizing OpEx in Steel Coil Packing And Strap

-

Which is Best Palletizing for Your Steel Coil Palletizing Lin

-

Top 5 Things to Consider when Purchasing a Packing Solution F

-

-

-

-

How to prevent coils being picked up missed together in coil

-

Guide of the Coil Car for Integrating the Coil Rewinder with

-

Turnkey Solution: Fully Automated Coil Slitting and Packing L

-

Automated Coil Strapping and Packing Line: Boost Efficiency a

-

-

Semi-Automatic and Fully Automatic Steel Coil Packing Lines D

-

How to Get the Most Out of Your Steel Coil Packing Line Throu

-

The Importance of Equipment Testing and Commissioning for Ste

-

How Our Installation and Support Services Ensure Minimal Down

-

Understanding the Pricing Structure for Steel Coil Packing Li

-

How We Provide Fast Solutions to Minimize Downtime for Steel

-

Lessons Learned: Best Practices from Successful Steel Coil Pa

-

.jpg)