Click to Chat

I'm online now.

Fhopepack Innovation

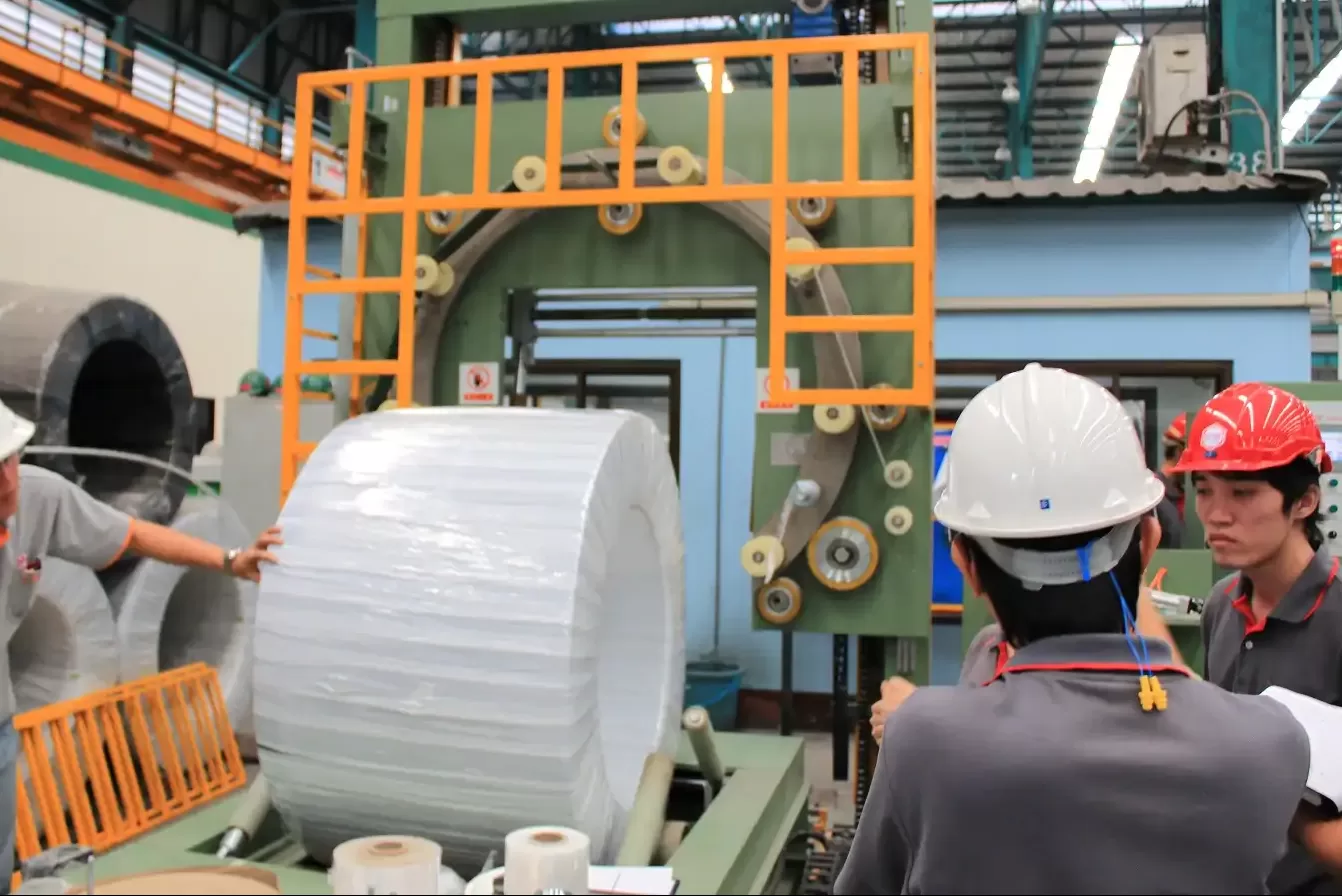

The Industrial Coil Wrapping Machine efficiently packages various types of coils with precision. It enhances protection during storage and transport, ensuring durability and reliability. Ideal for heavy-duty tasks, this machine streamlines operations and increases productivity in industrial settings.

These machines are equipped with advanced features like adjustable wrapping speeds ranging from 15 to 25 RPM and customizable coil diameter settings that support widths up to 2 meters. They utilize stretch film or VCI (Volatile Corrosion Inhibitor) wraps to prevent rust. Heavy-duty rollers with precision bearings provide smooth handling, while automated tension controls ensure consistent wrapping pressure, avoiding deformation of the steel coils. Some models also include automated film cutting and overlapping mechanisms, which reduce manual intervention and improve wrapping efficiency. With PLC (Programmable Logic Controller) systems, operators can easily configure wrapping patterns, ensuring flexibility and reliability for varying production requirements.

Technologically advanced wire coil wrapping machines offer diameter ranges from 300 mm to 1200 mm and can handle weights up to 2,000 kilograms. They often feature servo-controlled wrapping arms that ensure precise film placement, reducing gaps and overlaps. High-speed wrapping capabilities of up to 120 RPM allow for efficient processing, and optional add-ons like automatic edge protection applicators and integrated labeling systems enhance usability. Built-in tension sensors and material feeders ensure uniform wrapping across the coil, while optional IoT-enabled monitoring systems provide real-time feedback for enhanced production oversight.

Tyre wrapping machines support a variety of sizes, accommodating diameters from 400 mm to 1,200 mm and weights of up to 1500 kilograms per stack. They use stretch film or shrink wrap materials and feature variable-speed motors for wrapping speeds between 12 and 18 RPM. Precision rollers and pneumatic clamps ensure stability during wrapping, while automated film cutters and heat-sealing options deliver a secure, consistent finish. Advanced touch-screen interfaces allow operators to program wrap tension, rotation cycles, and film overlap to suit specific tyre types. With optional safety enclosures and energy-efficient designs, these machines offer a balance of productivity and operational safety.

Industrial coil wrapping machines for steel, wire, and tyres stand out for their tailored capabilities and technical sophistication. By incorporating advanced features like PLC systems, automated tension control, and IoT monitoring, these machines enhance operational efficiency and product protection. Their adaptability to various sizes, weights, and materials makes them essential tools for maintaining quality and reducing waste in diverse industries.

|

Coil parameters |

|

|

Object characteristic |

Steel coil |

|

Single coil weight |

100-4000kg |

|

Coil OD |

750-1600mm |

|

Coil ID |

508-610mm |

|

Coil width |

20-500mm |

|

Power supply |

380V-3p-50HZ |

|

Packing speed |

20-30 coils per hour |

The industrial landscape is evolving rapidly, with businesses demanding solutions that don’t just meet standards but surpass expectations. Packaging heavy, irregular, or delicate coils poses unique challenges, often requiring more than an off-the-shelf wrapping machine can provide.

In this era of customization and efficiency, industrial coil wrapping machines have taken center stage. These machines, designed to encase coils in protective packaging, must be tailored to meet the specific requirements of diverse industries. A standard solution may fail to address your operational nuances, costing you time, resources, and efficiency. This realization leads us to a pivotal question: how can a custom coil wrapping machine truly revolutionize your workflow?

Customization isn't just about aesthetics or minor tweaks; it’s about aligning the machine's capabilities with your operational demands. From ensuring seamless compatibility with existing systems to optimizing performance for your production volume, customization transforms a machine from a generic tool to a pivotal asset.

Industries dealing with heavy or non-standard coils often struggle with packaging irregularities. The shape, size, and weight of coils can vary drastically, and standard machines may fail to wrap them effectively. A custom machine, on the other hand, is engineered to adapt to these variations, ensuring that every coil is securely wrapped without compromising safety or quality.

When your product lines include diverse materials, from delicate copper coils to robust steel sheets, a tailored approach guarantees protection during transport and storage. This is particularly vital for industries like automotive manufacturing and energy, where damage to materials can disrupt the entire supply chain.

Customization goes beyond accommodating physical differences; it addresses industry-specific requirements. For instance, in sectors requiring moisture or corrosion-resistant packaging, a custom machine can be equipped with advanced film-handling technology to apply specialized wraps. This level of precision mitigates risks associated with environmental exposure.

Safety is another area where custom designs shine. Standard machines often neglect the unique handling and tension requirements of certain coil types. A custom solution incorporates features like automated tension control, ensuring the wrapping process doesn't deform or damage sensitive materials. This is particularly critical in industries where product integrity is non-negotiable, such as aerospace or medical equipment manufacturing.

Efficiency isn’t just about speed; it’s about creating systems that work in harmony with your existing processes. A customized industrial coil wrapping machine can integrate with conveyor systems, automated loaders, or ERP software, eliminating bottlenecks and manual interventions. Such seamless integration can lead to a dramatic reduction in downtime, translating into significant cost savings.

Imagine a scenario where your wrapping process takes minutes instead of hours, with every coil perfectly packaged and ready for shipping. Customization ensures that each aspect of the machine is calibrated for your specific workflow, maximizing productivity without compromising on quality.

A tailored machine often incorporates energy-efficient technologies, such as variable-speed motors or advanced sealing mechanisms, reducing electricity consumption. Moreover, these machines are designed with durability in mind, minimizing maintenance costs and extending operational lifespans.

While the upfront cost of customization might seem significant, the long-term return on investment (ROI) is often substantial. Consider the savings from reduced labor costs, fewer material losses due to improper wrapping, and improved customer satisfaction from receiving undamaged products. Over time, these benefits outweigh the initial expenditure, making customization a financially sound decision.

A critical advantage of custom industrial coil wrapping machines is their ability to integrate seamlessly into your existing workflow. Standard machines might require extensive adjustments to your production line, leading to disruptions or inefficiencies. In contrast, a custom solution is built around your operational environment, ensuring that installation and integration are smooth and minimally disruptive.

Whether you’re working with fully automated production lines or semi-automated systems, a custom machine can include features like synchronized operation with conveyors or compatibility with specific ERP software for real-time monitoring. This alignment enhances operational efficiency and eliminates unnecessary complexity.

Custom machines don’t just meet today’s needs; they prepare your business for tomorrow. If your production line is likely to expand or shift toward higher volumes, a custom coil wrapping machine can be designed with scalability in mind. Modular components, adjustable settings, and adaptable software allow your equipment to grow alongside your business without requiring a complete overhaul.

Maintenance is an inevitable part of any machine’s lifecycle, but a custom solution minimizes downtime. By designing the machine with your team’s expertise in mind, including accessible components and user-friendly diagnostics, the likelihood of prolonged interruptions decreases. Additionally, manufacturers of custom machines often provide tailored maintenance plans and spare parts, ensuring that your operations run smoothly.

When designing a custom coil wrapping machine, it’s crucial to prioritize features that directly impact your production goals. For instance, industries dealing with heavy-duty coils might need reinforced frames and advanced tension systems, while manufacturers working with sensitive materials might prioritize adjustable film tension and gentle handling mechanisms.

Another key consideration is speed. Depending on your output requirements, the machine can be designed to handle high volumes without compromising wrap quality. This ensures that your production meets deadlines without incurring extra labor or overtime costs.

The incorporation of cutting-edge technology enhances both the precision and efficiency of custom machines. Features like automated film application, real-time monitoring via IoT, and AI-driven diagnostics improve performance and reduce the risk of errors. These technologies not only optimize packaging but also provide actionable insights for further improvement.

Finally, durability should never be overlooked. A custom machine is a long-term investment, and its materials and components should reflect that. Choosing high-quality, wear-resistant parts ensures the machine withstands rigorous use over time. Manufacturers often provide warranties and support plans for custom machines, adding another layer of reliability to your operations.

Claim: Custom coil wrapping machines are a game-changing investment for industries seeking tailored solutions to packaging challenges.

From addressing unique operational demands to improving efficiency, safety, and cost-effectiveness, customization turns a standard machine into a strategic asset. Whether you’re looking to optimize material usage, enhance workplace safety, or ensure long-term reliability, a custom industrial coil wrapping machine delivers unmatched value.

In today’s competitive market, where precision and efficiency drive success, investing in customization isn’t just a choice—it’s a necessity. By aligning your equipment with your specific needs, you empower your business to achieve higher productivity, lower costs, and superior results.

I'm online now.