Click to Chat

I'm online now.

Fhopepack Innovation

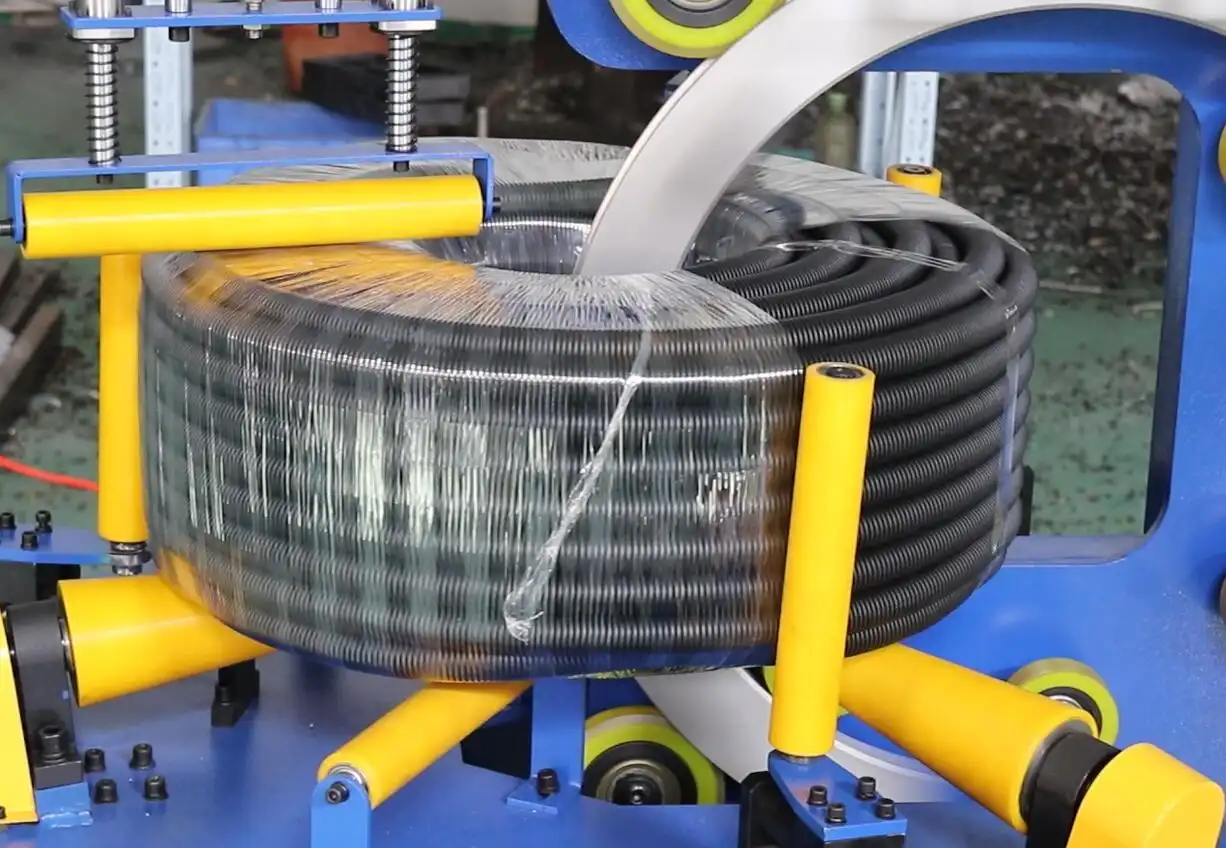

The pipe wrapping station features a rotating ring that is reinforced with a solid cast aluminum construction for durability. The driving wheels are made of polyurethane rubber, providing excellent traction and grip. The friction between the wheels and the ring ensures a smooth and efficient wrapping process for pipes. With its advanced design and high-quality construction, the pipe wrapping stati

The dynamics of supporting rollers: Motor-driven

Up/down protective rollers: Controlled by manual adjusterThe distance between protective rollers is adjustable for different size of tires.

|

Object weight |

5-100kg |

|

Package width |

100-350mm |

|

Package OD |

600-1400mm |

|

Package ID |

300-1200mm |

|

OD-ID |

<800mm |

|

Rotating speed |

20r-120r/min |

|

Wrapping speed |

12-30sec/pcs |

|

Overlap scope |

10%-90% |

|

Power output |

App. 2.0kw |

|

Power voltage |

380v/50Hz

|

|

Packing material |

PVC/ LLDPE film or others ID: 50mm OD: 100-200mm WIDTH: 100-120mm |

| Description | Brand |

| PLC | SIEMENS |

| Touch Screen(Option) | SIEMENS |

| Frequency Converters | Schneider |

| Motor | Dongli/Jiemai |

| Sensor | Autonics |

| Switch | Schneider |

| Contactor | Schneider |

I'm online now.