Click to Chat

I'm online now.

Fhopepack Innovation

The Coil Wrapping Machine for Aluminum Coil is designed to provide efficient, protective wrapping for aluminum coils, ensuring safe handling and transport. With automated precision, it applies consistent tension and secure packaging, reducing material waste. Ideal for aluminum manufacturers, this machine streamlines packaging processes and minimizes potential damage during shipping.

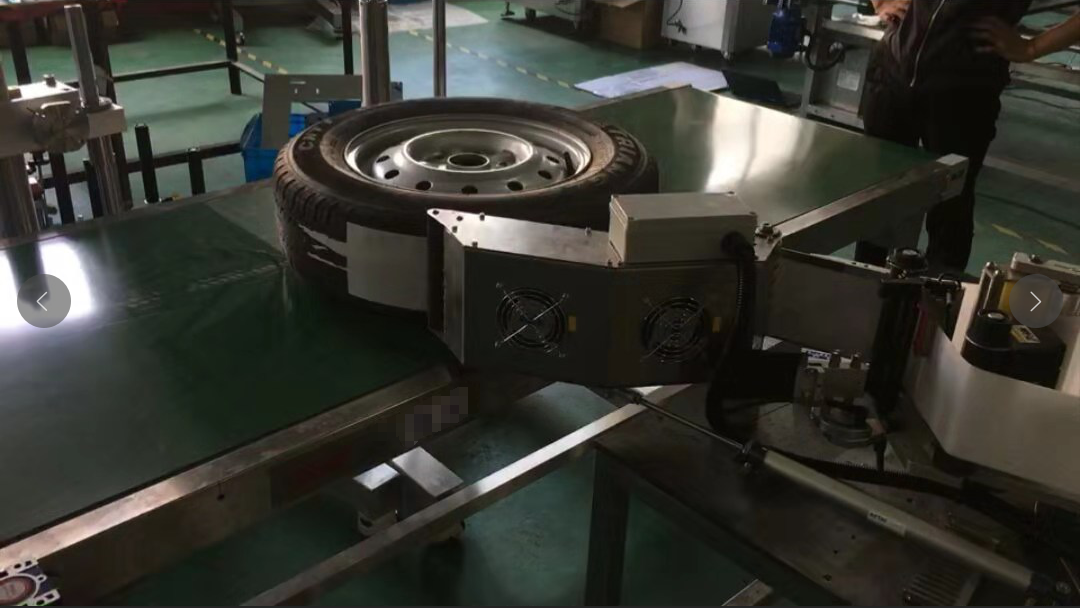

Coil wrapping machines for tyres come in various designs to accommodate different levels of automation, production volumes, and space constraints. Choosing the right type of machine can improve efficiency, consistency, and the overall quality of the packaging process. Here’s an overview of the primary types of tyre wrapping machines, each suited to specific operational requirements:

Semi-Automatic Tyre Wrapping Machines: Semi-automatic machines provide a blend of manual and automated functionality, making them suitable for mid-volume production environments. In these machines, operators are involved in setup and initial adjustments, while the machine automates the wrapping process itself. The wrapping material is fixed on a rotating ring, known as the “eye of the tyre,” which allows the material to wrap evenly around the tyre as it turns. Semi-automatic machines are ideal for operations that require more control over specific parameters, offering flexibility without sacrificing efficiency. They’re particularly useful for mid-sized facilities where the emphasis is on quality control, with some level of manual oversight in the packaging process.

Fully Automatic Tyre Wrapping Machines: Fully automatic machines are designed for high-volume production and require minimal human intervention. These machines streamline the wrapping process, making them ideal for facilities with large production demands. Key features include an automatic material dispenser with large rolls that minimize reloading time, allowing for uninterrupted wrapping even in fast-paced environments. Advanced functions, such as automatic length calculation and cutting, ensure precise material usage without wastage. Additionally, fully automatic machines often include automatic tapping for branding, automated in-feeding and out-feeding systems, and optional stacking capabilities. These features make fully automatic machines highly efficient, maintaining consistent wrapping quality and speed across extensive production runs.

Horizontal Wrapping Machines: Horizontal wrapping machines are widely used for larger or bulkier tyres, especially those in industrial applications. This type of machine wraps tyres while they are laid horizontally, making it easy to handle large volumes or heavy-duty tyres that may be cumbersome in a vertical setup. Horizontal wrapping machines are often equipped with integrated labeling, stacking, and inline packing features, allowing for efficient end-to-end processing. By consolidating multiple steps, horizontal machines are ideal for high-volume environments where streamlined packaging and labeling are essential. Additionally, the horizontal orientation offers added stability, reducing the likelihood of shifting or deformation during wrapping.

Vertical Wrapping Machines: Vertical wrapping machines are space-efficient and offer a cost-effective solution for companies with limited floor space or tighter budgets. Tyres are loaded vertically, making the machine footprint smaller and easier to accommodate in compact areas. Vertical machines are suitable for small to medium-sized tyres and are often found in facilities that prioritize space conservation. While not typically as fast as horizontal machines, vertical machines provide reliable wrapping with fewer space requirements, making them an excellent choice for businesses looking for economical solutions without sacrificing quality.

Selecting the right tyre wrapping machine depends on the specific requirements of the operation, including production volume, space constraints, and the level of automation desired. By aligning machine type with production needs, companies can optimize their wrapping processes, ensuring that tyres are securely protected, branded, and efficiently handled for storage or shipment.

|

Model |

Voltage (V/Hz) |

Power (KW) |

Coil ID (mm) |

Coil OD (mm) |

Coil Width (mm) |

Coil Weight (Kg) |

Packing Material |

|

|

FPW-300 |

customized

|

1.5 |

508-610 |

600-1200 |

100-300 |

20-1000 |

PVC/LLDPE/PE/PAPER/HDPE |

|

|

FPS-400 |

customized |

4.0 |

508-610 |

800-1400 |

100-400 |

100-2000 |

PVC/LLDPE/PE/PAPER/HDPE |

|

|

FPS-500 |

customizable |

2.0 |

508-610 |

700-1400 |

200-500 |

100-1000 |

PVC/LLDPE/PE/PAPER/HDPE |

|

|

FPS-600 |

customizable |

7.5 |

700-1100 |

1000-1500 |

200-600 |

200-2000 |

Crepe paper/plastic knit tape |

|

|

FPS-800 |

customizable |

7.5 |

508 |

800-1400 |

400-800 |

200-1000 |

PVC/LLDPE/PE/PAPER/HDPE |

|

|

FPCA-1000 |

customizable |

4.5 |

508-610 |

700-1600 |

20-400 |

100-2000 |

PVC/LLDPE/PE/PAPER/HDPE |

|

The automotive, aviation, and industrial equipment industries all rely on high-quality tyres for their equipment, which requires careful handling and storage. Coil wrapping machines designed for tyres have revolutionized the packaging process, offering secure wrapping that prevents damage, improves presentation, and streamlines transportation. This guide explores the functions, benefits, and best practices associated with coil wrapping machines for tyres, ensuring that companies maintain product integrity and operational efficiency.

Tyres, though inherently durable, are vulnerable to environmental and physical damage, making specialized wrapping essential for optimal protection, handling, and presentation. During transport and storage, tyres are exposed to dust, moisture, UV light, and physical impacts, all of which can lead to degradation. Dust and dirt not only affect the appearance of tyres but can also penetrate the rubber, potentially causing long-term material damage. Moisture exposure, particularly during prolonged storage, can lead to mold or compromise the rubber's structural integrity. Without a protective wrap, tyres may accumulate grime and dirt, affecting their aesthetics and requiring cleaning before they can be sold or installed.

Additionally, tyres can become deformed if improperly handled or stacked, especially over extended storage periods. Wrapping provides structure and stability, reducing the risk of deformation by holding each tyre in its ideal shape. This is especially valuable for larger tyres, which are harder to handle and prone to damage when moved or stored without adequate support.

Coil wrapping machines, specifically designed for tyres, offer a high-speed, efficient solution to protect and prepare tyres for the market. These machines apply a secure layer of protective film around each tyre, shielding it from dust, moisture, and impact damage. This film provides a barrier that ensures the tyre reaches customers in pristine condition. For warehouses and production facilities handling high volumes, specialized tyre wrapping machines enable fast, consistent packaging without compromising protection.

Tyre wrapping machines are designed to efficiently and securely wrap tyres with protective film, shielding them from dust, moisture, and potential damage during transport and storage. The process is straightforward yet highly effective, relying on a series of precise mechanical steps to create a tight, even wrap around each tyre. Here’s an overview of how these machines work and their essential components:

Tyre Turning Device: This component holds and rotates the tyre in a 360-degree motion, ensuring the wrapping film is applied evenly around the entire surface. Tyre wrapping machines typically use either a rotating turntable or supportive rollers to achieve this rotation. By rotating the tyre in a stable and controlled manner, the turning device allows the film to cover all exposed areas without gaps or overlaps, creating a uniform layer of protection.

Film Dispenser: The film dispenser is responsible for releasing the wrapping material around the tyre coil, controlling both the tension and speed of application. Proper tension control is critical, as too much tension could deform the tyre, while too little might leave sections inadequately wrapped. The dispenser often moves along a high-speed ring or arm that surrounds the tyre, applying the film smoothly as the tyre rotates. This controlled application minimizes material waste while ensuring a snug, damage-resistant wrap.

Control System: The control system allows operators to customize key parameters such as wrapping speed, film tension, and the type of wrapping material based on specific tyre dimensions and types. This adjustability is particularly important for operations handling a variety of tyre sizes, from small passenger tyres to larger industrial tyres. By setting the right parameters, operators can ensure each tyre is wrapped securely without risking damage or compromising efficiency.

Packing Material Cutter: Once the wrapping process is complete, the packing material cutter precisely trims the film to create a clean finish. The cutter operates automatically, leaving no loose edges or excess film that could come undone during transport. This clean cut not only improves the appearance of the packaged tyre but also secures the end of the wrap, preventing unraveling.

Tapping Device for Logo Application and Binding: For branding or additional security, many tyre wrapping machines include a tapping device, which applies labels, logos, or extra binding materials. This device can be programmed to add a specific logo or brand mark on the wrapping surface, enhancing brand visibility and ensuring consistent packaging presentation. Additionally, the tapping device can bind the end of the wrap, securing it firmly and ensuring the tyre remains tightly wrapped throughout handling and transit.

Together, these components enable tyre wrapping machines to provide a professional, even, and secure finish that not only protects the tyres from external damage but also facilitates easier handling and storage. By automating the wrapping process, these machines maintain high-speed, consistent packaging that meets the demands of production lines and large-scale warehouses, preserving tyre quality and enhancing overall operational efficiency.

High-quality tyre wrapping machines are designed with specific features to accommodate a variety of needs:

These features make tyre wrapping machines adaptable and efficient, enabling them to handle diverse wrapping requirements with ease.

Using coil wrapping machines for tyres offers numerous advantages:

These benefits make tyre wrapping machines a valuable addition to facilities that prioritize quality and operational efficiency.

Automation is a game-changer for facilities with high-volume production. Automated machines streamline the wrapping process, ensuring consistent, accurate wraps with minimal manual oversight. For companies that deal with large numbers of tyres, automation minimizes human error, reduces labor costs, and enhances the speed and accuracy of packaging, allowing production to keep pace with demand.

I'm online now.