Click to Chat

I'm online now.

Fhopepack Innovation

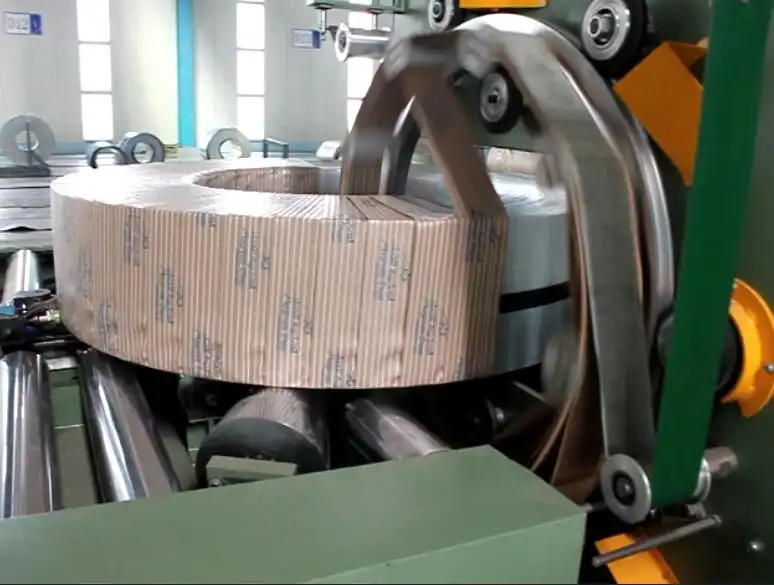

The Automatic Coil Wrapping Machine for Slit Coil Strips is designed to streamline packaging processes, offering efficient, consistent wrapping for various coil sizes. This machine enhances product protection, reduces labor costs, and increases packaging speed. Its adjustable features accommodate diverse requirements, making it ideal for industrial coil handling and safe transportation.

Dealing with slit coil strips can be a real headache, right? You've got these narrow, often sharp-edged coils that are prone to damage, unravelling, or causing safety issues if not handled and packaged correctly. Maybe you're spending too much time manually strapping or wrapping them, only to find inconsistencies, or worse, customer complaints about damaged goods upon arrival. It's a common frustration in the industry, and it eats into your efficiency and bottom line.

Yes, an automatic coil wrapping machine is very often the definitive answer to the challenges of packaging slit coil strips, offering significant improvements in speed, consistency, protection, and safety compared to manual or semi-automatic methods. These machines are specifically designed to handle the unique characteristics of slit coils, ensuring they reach their destination in perfect condition.

I've been in the packaging machinery world for a long time now, starting from the factory floor and eventually building FHOPEPACK. We're all about being master wrapping machine providers. Over the years, I've seen countless businesses transform their operations by adopting the right automation. Slit coil packaging is one area where the impact is incredibly visible. If you're looking to not just solve a problem but to genuinely upgrade your process, understanding these machines is key. Let's dive into why they are so effective and what you should consider.

Ever tried wrestling with a heavy, narrow slit coil, trying to get an even wrap around it by hand? It's tough, time-consuming, and often leads to a less-than-perfect package. You might be facing issues like loose wraps, coil telescoping, edge damage from handling, or even injuries to your team from sharp edges or repetitive strain. These aren't just minor annoyances; they add up to real costs in materials, labor, and potentially damaged products.

Slit coils are challenging due to their narrow width, potential for sharp edges, tendency to unwind (telescope), and the precision required for a secure, protective wrap; automatic machines solve this by providing consistent tension, complete coverage through orbital wrapping, and secure sealing, all without direct manual handling during the wrapping process. This automation directly addresses the core difficulties of manual packaging.

When we talk to clients at FHOPEPACK before they switch to automation, we hear a lot of the same stories. "Our guys are spending half their day just trying to get these coils ready for shipping," or "We had a whole pallet rejected last month because the coils shifted and got damaged." It's these real-world problems that drive the need for a better solution. And that's where automatic wrappers really shine. They take the variability and physical strain out of the equation.

Manually packaging slit coils is often a multi-step, labor-intensive process. Let's break down some common pain points:

Automatic slit coil wrapping machines are engineered to specifically address these manual packaging shortcomings:

At FHOPEPACK, our mission is to share knowledge and help businesses improve. Seeing a company go from struggling with manual packaging to effortlessly shipping perfectly wrapped slit coils with an automatic machine is one of the most rewarding parts of what we do. It’s not just about selling a machine; it’s about providing a genuine solution that impacts their entire operation.

So, you're considering an automatic wrapper for your slit coils. That's a great step! But not all machines are created equal, especially when it comes to the specific needs of narrow, potentially delicate slit coils. You might be wondering what features truly make a difference, ensuring you get a machine that’s a workhorse, not a headache.

Key must-have features for an automatic slit coil wrapping machine include a robust orbital wrapping ring or arm for "through-the-eye" wrapping, adjustable film tension control with powered pre-stretch, durable coil support and guide rollers (often polyurethane-coated), automatic film clamping and cutting, and a user-friendly PLC control system with programmable wrap patterns. These features directly address the unique challenges of securing and protecting slit coils.

When we design machines at FHOPEPACK, or when I advise clients, we focus on the practicalities. It's not just about a long list of features; it's about the right features that deliver reliability and performance day in, day out. Think of it like buying a car – you need an engine that runs smoothly, brakes that work every time, and steering that's responsive. The same applies to your wrapping machine.

For slit coils, the wrapping mechanism is paramount.

How the machine delivers the stretch film (or other wrapping material like VCI paper or knit belt) is crucial for both package integrity and material savings.

How the machine holds and manipulates the coil during wrapping is key to preventing damage.

A powerful machine is only as good as its control system.

I always tell people, when you're investing in a machine like this, think about the long term. At FHOPEPACK, we build for durability and ease of maintenance because we know that downtime is a killer. Features like high-quality components from reputable brands, clear labeling, and good access for maintenance might not be the flashiest, but they are incredibly important for the overall value and performance of your automatic slit coil wrapper.

You've got your slitting line running, producing coils efficiently. But what happens after that? If your packaging is a bottleneck, it's dragging down the entire line's performance. You might be wondering just how much of a difference an automatic wrapper can truly make. Is it just about wrapping faster, or are there deeper impacts on your overall efficiency?

Integrating an automatic slit coil wrapper transforms production line efficiency by significantly increasing packaging throughput, reducing labor dependency for wrapping tasks, ensuring consistent package quality which minimizes rework or damage, and enabling smoother material flow from production to shipping. This creates a more streamlined, predictable, and cost-effective end-of-line process.

I've seen this transformation firsthand many times. A client running a busy service center was struggling to keep up with their slitting output. Coils were piling up, waiting to be manually wrapped. It was chaotic. After we installed an automatic wrapper, integrated with their exit conveyor, the change was night and day. The packaging area became organized, coils flowed smoothly, and they could actually handle more output from their slitters without adding packaging staff. It’s about creating a balanced and synchronized operation.

Let's look at the specific ways an automatic wrapper boosts your line's efficiency:

Massive Throughput Increase:

Reduced Labor Costs & Redeployment:

Improved Material Flow & Reduced Bottlenecks:

Enhanced Package Consistency and Quality:

To get the most out of your automatic wrapper, consider how it integrates with your existing line:

The goal is to create a packaging process that is as smart and efficient as your production process. When your end-of-line packaging can keep pace with, or even outpace, your production, you unlock new levels of overall plant efficiency. It’s about looking at the bigger picture, not just the wrapping machine in isolation.

When you're looking at investing in new equipment, the upfront cost of an automatic slit coil wrapping machine is obviously a big factor. But just focusing on that price tag can be misleading. You might ask, "Sure, it's faster, but will it really pay for itself?" The answer, in most cases, is a resounding yes, often much quicker than you'd think. The key is to look at the total return on investment (ROI), which goes far beyond just labor savings.

The real ROI of an automatic slit coil wrapping system encompasses not only direct labor savings and increased throughput, but also significant reductions in material waste, lower damage rates, improved worker safety (reducing compensation costs), enhanced product presentation, and greater operational flexibility. These combined benefits contribute to a faster payback period and ongoing financial advantages.

At FHOPEPACK, we always encourage potential clients to look at the complete picture. I’ve seen businesses hesitate due to the initial investment, only to realize a year later that they could have saved more than the machine's cost if they'd acted sooner. It's about understanding all the ways automation puts money back into your pocket or prevents it from unnecessarily flowing out.

Let's break down where the savings and value come from:

Reduced Labor Costs:

Increased Throughput & Productivity:

Material Savings (Stretch Film/Other):

Reduced Product Damage & Rejects:

These are harder to put an exact number on initially, but they are very real and contribute significantly to the overall value:

While a detailed ROI calculation should be specific to your operation, here's a basic idea:

Many companies find that automatic wrapping systems, especially for high-volume or problematic products like slit coils, can have a payback period of less than two years, sometimes even under a year. After that, the ongoing savings directly contribute to your profitability.

My advice, as someone who's dedicated their career to packaging solutions with FHOPEPACK, is to not just look at the price tag. Engage with potential suppliers, discuss your specific needs, and ask them to help you quantify the potential ROI. A good partner will be transparent and help you build a solid business case. The goal of MASTER WRAPPING MACHINE isn't just a slogan; it's about empowering you with the best, most cost-effective solutions.

Ultimately, automating your slit coil wrapping isn't just an upgrade; it's a strategic move towards greater efficiency, safety, and profitability in today's competitive manufacturing landscape.

|

Model |

Voltage (V/Hz) |

Power (KW) |

Coil ID (mm) |

Coil OD (mm) |

Coil Width (mm) |

Coil Weight (Kg) |

Packing Material |

|

|

FPS-300 |

customized

|

1.8 |

508-610 |

600-1000 |

100-300 |

20-1000 |

PVC/LLDPE/PE/PAPER/HDPE |

|

|

FPS-400 |

customized |

3.0 |

508-610 |

800-1400 |

100-400 |

100-2000 |

PVC/LLDPE/PE/PAPER/HDPE |

|

|

FPS-500 |

customizable |

2.0 |

508-610 |

700-1600 |

200-500 |

100-2000 |

PVC/LLDPE/PE/PAPER/HDPE |

|

|

FPS-600 |

customizable |

7.5 |

508-610 |

1000-1600 |

200-600 |

200-4000 |

Crepe paper/plastic knit tape |

|

|

FPS-800 |

customizable |

7.5 |

508-610 |

800-1600 |

400-800 |

200-5000 |

Fabric/LLDPE/PE/PAPER/HDPE/ |

|

|

FPCA-1200 |

customizable |

4.5 |

508-610 |

700-1800 |

10-400 |

100-4000 |

Fabric/LLDPE/PE/PAPER/HDPE |

|

In industries that manufacture, store, and transport steel strips, efficient coil wrapping is vital for protecting the product against damage and corrosion. Investing in a high-performance coil wrapping machine can dramatically improve both the speed and quality of packaging processes, ensuring steel coils arrive in perfect condition. But with so many options on the market, how do you choose the right one? This guide covers all the essential features to look for in a high-performance coil wrapping machine, helping you make a decision that benefits your production line and bottom line.

A coil wrapping machine is a specialized piece of equipment designed to wrap steel coils with protective materials, such as stretch film, VCI (Volatile Corrosion Inhibitor) paper, or other coverings, to prevent surface damage, corrosion, and contamination. These machines vary in design, with options for fully automated systems that streamline the entire wrapping process and semi-automatic machines that require some manual input. Industrial coil wrapping machines are particularly suited for sectors like construction, automotive, and manufacturing, where steel strips are frequently exposed to adverse conditions during storage and shipping.

A high-performance coil wrapping machine enhances productivity and reliability on the production line. With advanced automation, faster wrapping speeds, and durable construction, these machines ensure consistent, high-quality wrapping that keeps steel coils protected throughout their lifecycle. High-performance machines also reduce waste by applying precise amounts of wrapping material, which helps lower operational costs while maximizing product safety.

When selecting a coil wrapping machine, it’s crucial to consider various factors that impact long-term efficiency, reliability, and adaptability. Here’s a closer look at each of these essential criteria:

The first thing to evaluate is whether the machine can handle the specific dimensions and weights of the steel coils your operation processes. High-performance coil wrapping machines are typically built to accommodate a wide range of coil sizes and can handle coils weighing thousands of pounds. Ensure that the machine can support the maximum weight capacity needed in your facility to avoid overloading the equipment, which could lead to safety hazards or mechanical breakdowns.

A high wrapping speed is essential in fast-paced production environments, where productivity depends on the ability to wrap coils quickly and effectively. Many high-performance machines are designed to offer faster wrapping speeds, reducing downtime and improving throughput. However, it’s essential to choose a machine that balances speed with precision, ensuring that the wrapping material is applied smoothly and securely.

In modern manufacturing, flexibility is key. High-performance coil wrapping machines are often built to handle a variety of coil diameters and widths, allowing for greater adaptability to changing production demands. Adjustable settings, including wrap tension and overlap, offer better control over the wrapping process, which is especially beneficial when working with different coil sizes or sensitive materials.

The quality of materials compatible with a coil wrapping machine can significantly affect the outcome. High-performance machines are often designed to work with various protective materials, such as stretch film, VCI paper, and HDPE (High-Density Polyethylene) sheeting. The ability to choose the right material allows operators to ensure optimal protection for each coil, whether it’s destined for long-term storage or immediate use in production.

One of the most valuable aspects of high-performance machines is their advanced automation capabilities. Automated coil wrapping machines offer programmable settings for consistent, hands-free operation, which minimizes the risk of operator error. Touchscreen controls, pre-programmable wrap cycles, and automatic film cut-off options make these machines user-friendly and increase operational speed and reliability. Look for machines with flexible control options that allow easy adjustments for different types of coils.

High-performance machines are equipped with safety features to ensure operator protection. Emergency stop buttons, motion sensors, and safety guards are essential components in any industrial machine, preventing accidents and enabling safe operation in high-demand settings. OSHA-compliant safety protocols and mechanical locks can further ensure that the equipment operates safely even under heavy loads.

For facilities focused on cost-effectiveness and sustainability, energy efficiency is a critical consideration. High-performance coil wrapping machines often incorporate energy-saving technologies, such as motor power regulation and automated shut-off mechanisms, which reduce overall energy consumption. Efficient machines not only lower your electricity bills but also reduce the carbon footprint of your operations.

Maintenance is crucial for keeping high-performance coil wrapping machines running smoothly. Opt for machines designed with easy access to critical components, as this simplifies both routine checks and repairs. High-performance models often include self-diagnostics features that alert operators to potential issues before they become major problems, minimizing downtime and maintenance costs. Additionally, select a model from a vendor known for reliable service and spare parts availability.

When investing in a high-performance coil wrapping machine, it’s essential to choose a reputable vendor with proven reliability. Look for manufacturers that offer robust warranties, flexible support plans, and fast response times. A trustworthy vendor will provide necessary training for your team, ensuring they know how to operate the machine effectively and troubleshoot minor issues, thereby maximizing the equipment’s lifespan.

A high-performance coil wrapping machine can significantly boost your operations:

Selecting the right coil wrapping machine involves aligning its capabilities with your specific production needs. Start by assessing your production volume, coil dimensions, and the types of materials used for wrapping. Next, consider the machine’s operational features, such as speed, automation, and flexibility, which play critical roles in meeting your production demands. Lastly, choose a reliable vendor offering strong support and warranties for added peace of mind.

As technology advances, coil wrapping machines are integrating new features like IoT connectivity, allowing for real-time monitoring and predictive maintenance. Advanced sensors help monitor machine wear and tear, alerting operators to potential issues before they lead to downtime. These innovations contribute to better equipment longevity and higher efficiency, aligning with the Industry 4.0 shift toward smart manufacturing.

Investing in a high-performance coil wrapping machine for steel strips can revolutionize your production line, providing faster, more reliable, and cost-effective wrapping solutions. From size and weight capacity to automation and energy efficiency, each feature plays a vital role in ensuring that the machine fits seamlessly into your operations. By focusing on these essential criteria, you’ll find a coil wrapping machine that not only meets your current needs but also scales with future growth.

What materials are compatible with coil wrapping machines?

Can I wrap coils of various sizes on one machine?

How often should a coil wrapping machine be serviced?

What is the average cost of a high-performance coil wrapping machine?

How do automation features impact production speed?

I'm online now.