Click to Chat

I'm online now.

Fhopepack Innovation

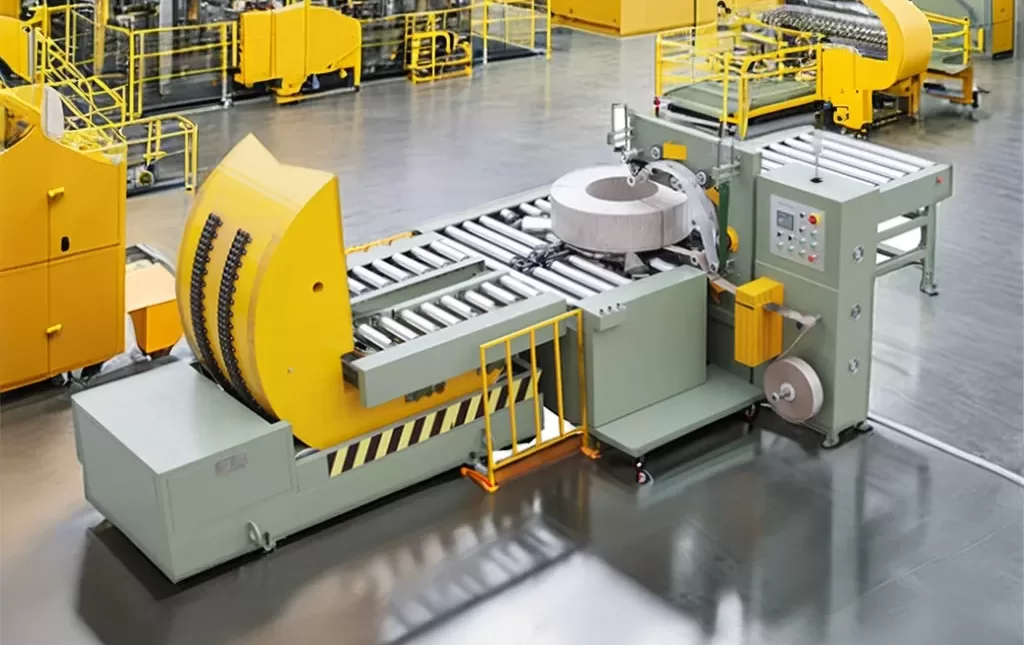

The Coil Wrapping Machine for Steel Coil offers reliable and consistent packaging, specifically tailored for steel coils. It wraps coils tightly, safeguarding them from environmental damage and abrasion during transport. This machine enhances efficiency and minimizes labor, providing a cost-effective solution for secure coil handling and delivery.

Manual Coil Wrapping Machines: These machines are fully operated by hand, making them suitable for small-scale or low-volume production. Operators handle all steps of the wrapping process, from loading the coil to applying the protective material. Manual machines are cost-effective and ideal for companies with limited wrapping needs, though they require more time and labor compared to automated options.

Semi-Automatic Coil Wrapping Machines: Semi-automatic machines incorporate a blend of manual and automated features. While operators are needed to load the coils and initiate the wrapping process, the machine handles the application of the wrap, ensuring even coverage. These machines offer a balance between efficiency and cost, making them ideal for medium-sized operations where a higher wrapping speed is needed, but full automation is unnecessary or impractical.

Fully Automatic Coil Wrapping Machines: Fully automated machines are designed for high-volume operations and require minimal human intervention. Once the coils are loaded onto the machine, it handles the entire wrapping process, from initiating the wrap to cutting and securing the material. These machines are equipped with advanced control systems and sensors to ensure optimal wrapping speed and consistency, making them ideal for large-scale facilities focused on high output and uniform packaging.

|

Model |

Voltage (V/Hz) |

Power (KW) |

Coil ID (mm) |

Coil OD (mm) |

Coil Width (mm) |

Coil Weight (Kg) |

Packing Material |

|

|

FPW-300 |

customized

|

1.5 |

508-610 |

600-1200 |

100-300 |

20-1000 |

PVC/LLDPE/PE/PAPER/HDPE |

|

|

FPS-400 |

customized |

4.0 |

508-610 |

800-1400 |

100-400 |

100-2000 |

PVC/LLDPE/PE/PAPER/HDPE |

|

|

FPS-500 |

customizable |

2.0 |

508-610 |

700-1400 |

200-500 |

100-1000 |

PVC/LLDPE/PE/PAPER/HDPE |

|

|

FPS-600 |

customizable |

7.5 |

700-1100 |

1000-1500 |

200-600 |

200-2000 |

Crepe paper/plastic knit tape |

|

|

FPS-800 |

customizable |

7.5 |

508 |

800-1400 |

400-800 |

200-1000 |

PVC/LLDPE/PE/PAPER/HDPE |

|

|

FPCA-1000 |

customizable |

4.5 |

508-610 |

700-1600 |

20-400 |

100-2000 |

PVC/LLDPE/PE/PAPER/HDPE |

|

In the world of steel manufacturing, packaging and handling are essential steps for ensuring product quality and safety. Coil wrapping machines for steel coils have revolutionized these processes, providing protection, efficiency, and reliability. These machines apply protective films around steel coils, securing them for storage or transport. With advanced automation, today’s coil wrapping machines enhance both productivity and safety, making them essential equipment in modern steel mills and distribution centers.

Steel coils are prone to damage from moisture, dust, and physical impact, making protective wrapping vital. During transport and storage, unwrapped coils can rust, suffer from corrosion, or even deform under poor handling conditions. Wrapping helps maintain the integrity of the steel, preserving its quality and extending its shelf life. Wrapping also serves as a form of branding, providing an aesthetic finish that appeals to customers while allowing companies to add labeling or logos for easy identification.

To achieve this seamless wrapping process, these machines rely on several critical components working in concert:

The Turntable: This is the foundation of the wrapping operation. Designed to securely hold and rotate even the heaviest of steel coils, the turntable is precisely engineered to provide smooth, consistent rotation. Its stability is crucial for preventing imbalances and ensuring that the film is applied uniformly across the entire surface of the coil. Advanced turntables often feature variable speed controls, allowing operators to optimize rotation speed based on coil size and desired wrap density.

The Film Dispenser (or Film Carriage): This is where the magic of film application happens. The film dispenser is much more than just a holder for the film roll. It's equipped with a sophisticated tension control system that ensures the film is applied with just the right amount of stretch and tightness. Too little tension, and the wrap will be loose; too much, and the film could snap. Modern dispensers often include powered pre-stretch units, which stretch the film before it's applied, maximizing its yield and enhancing puncture resistance. Furthermore, the dispenser precisely controls the film's feed rate and overlap, guaranteeing complete and uniform coverage with each revolution. Many systems also integrate automated film cutting and clamping mechanisms for efficient operation.

The Control System: This is the "brain" of the operation, providing operators with unparalleled control over the wrapping process. Through an intuitive interface, typically a touchscreen HMI (Human-Machine Interface), operators can program and adjust a myriad of parameters. This includes setting the desired number of film layers (wraps), regulating the film tension for optimal security, adjusting the wrapping speed for efficiency, and even defining specific wrapping patterns for different coil types or protection levels. These systems often store multiple wrapping recipes, allowing for rapid changeovers and consistent quality across various product lines. They also incorporate safety interlocks and diagnostic features to ensure smooth and secure operation.

Horizontal Wrapping Machines are often used for large steel coils, while Vertical Wrapping Machines are better suited for smaller coils or applications with limited space.

A high-quality coil wrapping machine for steel applications should offer:

Additionally, machines with advanced safety features, such as emergency stop buttons and protective guards, ensure operator safety while maintaining high efficiency.

Investing in coil wrapping machines for steel coils transcends mere automation; it's a strategic move that delivers significant returns in product quality, operational efficiency, and customer satisfaction. By streamlining the packaging process, these machines fortify your steel products against myriad challenges from the factory floor to the final destination.

Here's a detailed look at the core advantages:

To illustrate the tangible impact, consider a hypothetical comparison between manual and automated coil wrapping for a typical production scenario:

| Feature | Manual Coil Wrapping (per coil) | Automated Coil Wrapping (per coil) | Benefit / Improvement |

|---|---|---|---|

| Wrapping Time | 8 - 10 minutes | 1 - 2 minutes | 80-90% faster |

| Labor Requirement | 1-2 dedicated operators | 1 operator (monitoring multiple units) | Significant labor reduction |

| Film Material Usage | High (prone to inconsistency) | Optimized (consistent tension/overlap) | 15-25% material savings |

| Packaging-Related Damage | 5 - 10% rate | < 1% rate | Up to 90% reduction in damage claims |

| Consistency of Wrap | Variable, operator-dependent | Highly consistent, machine-controlled | Uniform quality and protection |

| Product Presentation | Often inconsistent, less professional | Neat, uniform, professional | Enhanced customer perception |

These compelling benefits underscore why coil wrapping machines are not just an operational upgrade but a strategic investment for companies aiming to improve their production quality, reduce costs, enhance customer satisfaction, and maintain a competitive edge in the steel industry.

Automation in coil wrapping significantly enhances productivity by reducing manual handling and increasing wrapping speed. Automated machines can wrap coils with consistent tension and precision, decreasing the likelihood of damage during transport or storage. This reduction in manual intervention not only speeds up operations but also improves consistency, leading to higher-quality outcomes.

The wrapping material is key to effective coil protection. Common options include:

Choosing the right material depends on factors like coil size, transportation conditions, and storage environment.

How does a coil wrapping machine differ for steel compared to other materials?

What materials are best for wrapping steel coils?

Can one machine handle different coil sizes?

What are the environmental benefits of using coil wrapping machines?

How often should coil wrapping machines undergo maintenance?

I'm online now.