Click to Chat

I'm online now.

Fhopepack Innovation

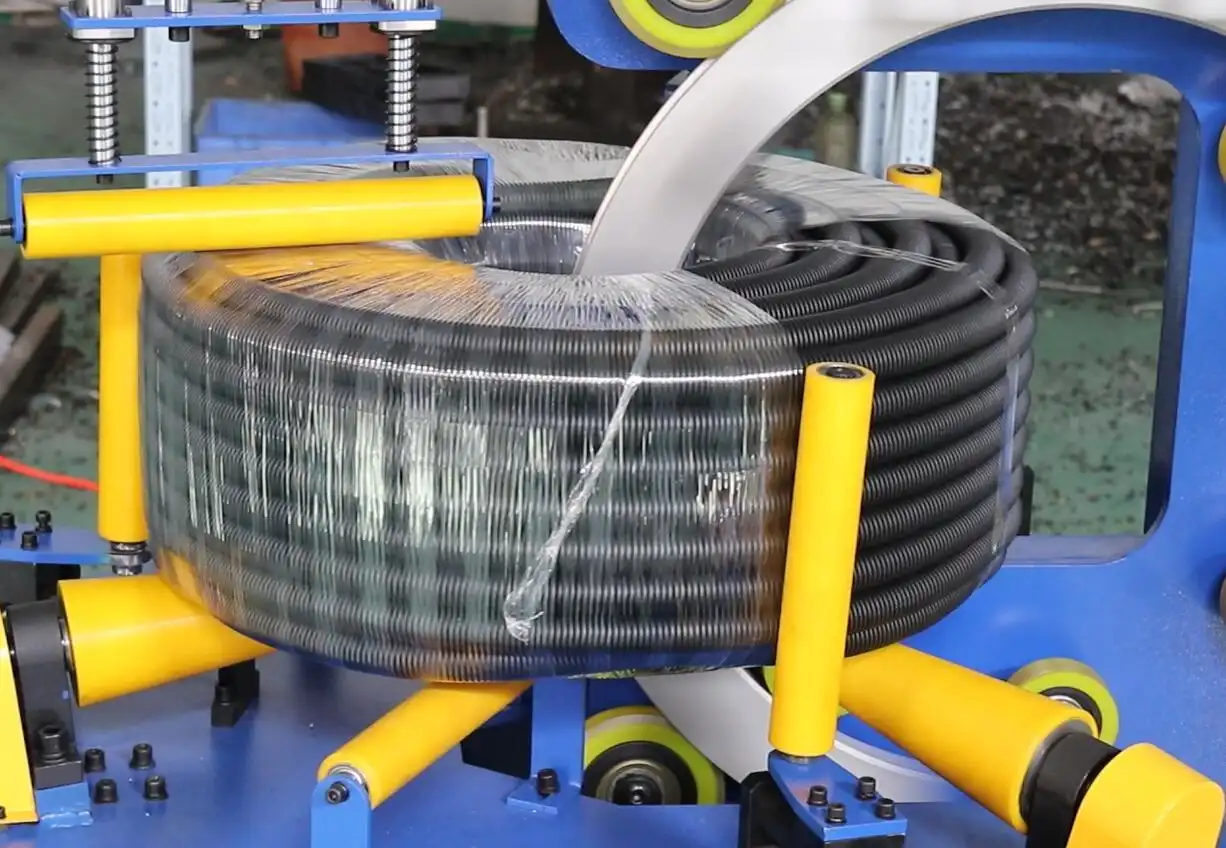

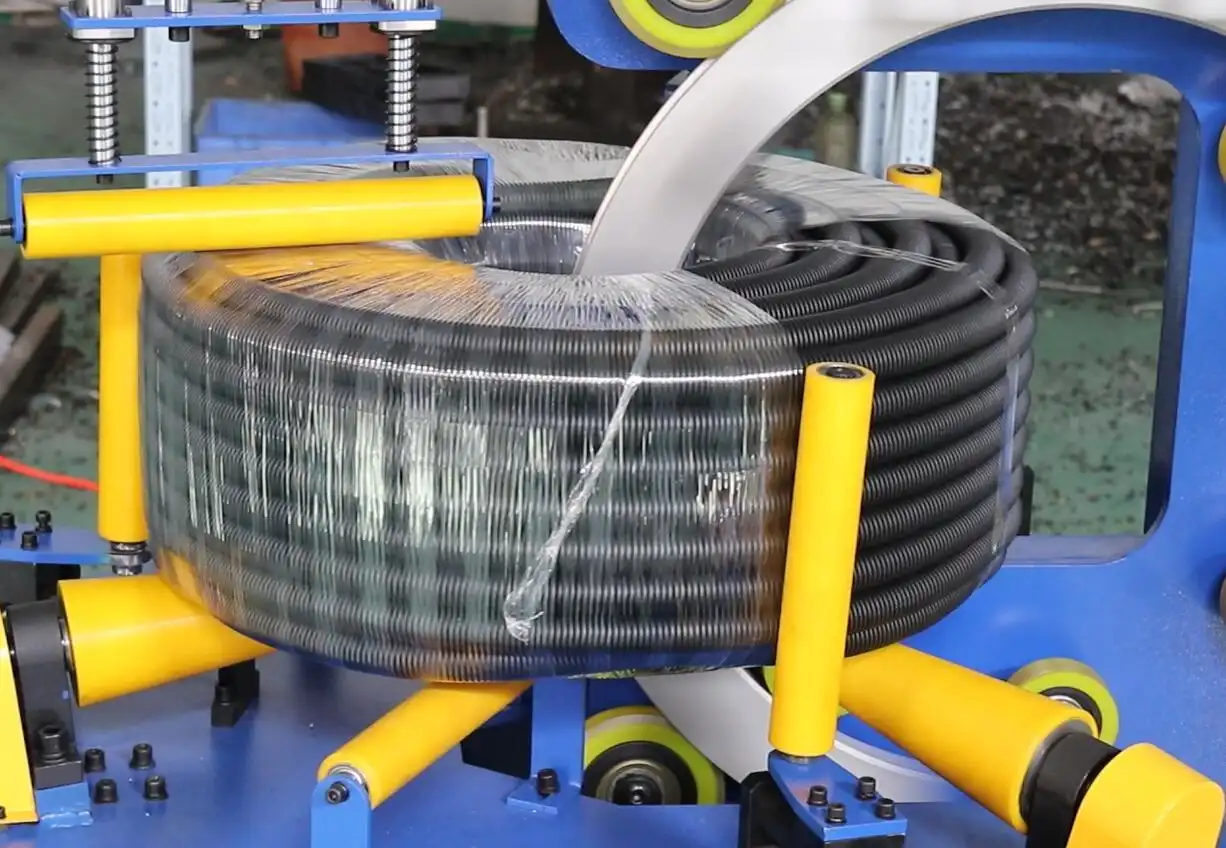

This coil wrapping machine is engineered specifically for hose coils, providing consistent and efficient wrapping that safeguards products during handling and shipping. With customizable settings, it optimizes material usage while maintaining coil integrity, making it an ideal choice for industries requiring reliable, high-quality packaging solutions.

Hose coil wrapping machines are essential for efficiently and securely packaging hose coils, and they come in various types to suit different production scales and automation needs. Each type of machine has unique mechanical features designed to optimize productivity, enhance protection, and provide flexibility based on the size and volume of the coils. Here’s an in-depth look at the types of hose coil wrapping machines, along with their structural specifics:

Manual Hose Coil Wrapping Machines: These machines are cost-effective and feature a straightforward mechanical design, primarily used for small-scale operations. In manual machines, operators handle coil loading, positioning, and wrap material feeding. The machine typically includes a rotating spindle or small turntable that allows the coil to turn as the operator applies the wrap manually. Due to their simple structure, manual machines are lightweight and easy to maintain but depend heavily on operator precision. They’re well-suited for businesses with low-volume wrapping requirements or where budget constraints limit investment in automation.

Semi-Automatic Hose Coil Wrapping Machines: These machines blend manual and automated processes, striking a balance between cost and productivity. Operators load and unload hose coils, but the machine manages the wrapping process independently, using a powered rotation system. Semi-automatic machines often include a ring or arm that moves along the coil’s circumference, applying the wrap at a consistent tension. Advanced models may include an automatic film-feeding mechanism, which reduces material handling by the operator, and sensors that control wrapping tension. This structural design makes semi-automatic machines ideal for medium-scale operations, offering speed and efficiency without fully automated features.

Fully Automatic Hose Coil Wrapping Machines: Fully automated machines are designed for high-volume production, with advanced mechanics that require minimal human intervention. These machines feature conveyors or automatic loading and unloading systems that transport the hose coils through the wrapping process seamlessly. Key structural components include a large rotating ring or frame, which moves around the stationary coil to apply the wrap automatically. Built-in tension control systems and film cutters ensure that each coil is wrapped tightly and precisely. Fully automatic machines also include programmable control panels, allowing operators to adjust parameters like wrapping speed and tension, making them versatile for high-output facilities where speed and consistency are critical.

Horizontal Wrapping Machines: These machines are specifically designed for larger hose coils and use a horizontal spindle or rotating arm to wrap the material around the coil’s circumference. Horizontal wrapping machines are with a wide structure that accommodates larger coils to avoide the coil deforming in wrapping. They often include adjustable rollers to secure the coil in place, ensuring even wrapping across the entire surface. Horizontal wrapping machines are well-suited for applications requiring stability and high precision for larger hose coils.

Vertical Hose Wrapping Machines: Ideal for smaller coils and compact spaces, vertical wrapping machines have a more compact design with a vertical rotating mechanism that wraps the hose coil as it stands upright. These machines are commonly used where floor space is limited and are designed to handle smaller coils efficiently. With the coil positioned vertically, these machines allow for faster loading and unloading, which is useful in facilities where space optimization and swift operation are priorities.

|

Model |

Voltage (V/Hz) |

Power (KW) |

Coil ID (mm) |

Coil OD (mm) |

Coil Width (mm) |

Coil Weight (Kg) |

Packing Material |

|

|

FPW-300 |

customized

|

1.5 |

508-610 |

600-1200 |

100-300 |

20-1000 |

PVC/LLDPE/PE/PAPER/HDPE |

|

|

FPS-400 |

customized |

4.0 |

508-610 |

800-1400 |

100-400 |

100-2000 |

PVC/LLDPE/PE/PAPER/HDPE |

|

|

FPS-500 |

customizable |

2.0 |

508-610 |

700-1400 |

200-500 |

100-1000 |

PVC/LLDPE/PE/PAPER/HDPE |

|

|

FPS-600 |

customizable |

7.5 |

700-1100 |

1000-1500 |

200-600 |

200-2000 |

Crepe paper/plastic knit tape |

|

|

FPS-800 |

customizable |

7.5 |

508 |

800-1400 |

400-800 |

200-1000 |

PVC/LLDPE/PE/PAPER/HDPE |

|

|

FPCA-1000 |

customizable |

4.5 |

508-610 |

700-1600 |

20-400 |

100-2000 |

PVC/LLDPE/PE/PAPER/HDPE |

|

Coil wrapping machines for hose coils play a crucial role in packaging, protecting, and enhancing the presentation of hose products. Whether for industrial, automotive, or gardening applications, hoses are coiled for convenient storage and handling, but they need adequate protection to remain in optimal condition. These wrapping machines apply protective films around hose coils, safeguarding them from dust, moisture, and handling damage. This guide explores the importance, functionality, and advantages of coil wrapping machines tailored for hose coils.

Hose coils are particularly vulnerable to damage from dust, UV exposure, and physical wear during storage and transport. Wrapping hose coils helps prevent kinks and abrasions, maintaining the hose’s shape and usability. Additionally, hoses are often stored for long periods, making it essential to keep them free from moisture and contaminants. Specialized wrapping provides a barrier that prolongs the hose’s lifespan, ensuring it reaches customers in pristine condition.

Hose coil wrapping machines work by securing a hose coil onto a rotating turntable and applying a film wrap around it in a uniform manner. Key components in these machines include:

This efficient wrapping process enhances both the durability and aesthetic of hose packaging, while also minimizing handling time.

High-quality hose coil wrapping machines include features that improve wrapping precision and operator efficiency:

These features ensure that the machine can handle a wide range of hose types and sizes, enhancing both flexibility and efficiency in packaging operations.

Using coil wrapping machines for hoses offers several advantages:

These benefits contribute to reduced product damage, improved customer satisfaction, and better cost management in packaging.

Automation in hose coil wrapping allows companies to meet high production demands with minimal labor. Automated machines provide consistent, secure wrapping, reducing the need for rework and minimizing human error. For high-volume hose manufacturers, this ensures faster output and a higher level of product consistency, making automation an essential aspect of efficient packaging operations.

Choosing the correct wrapping material for hose coils is essential for maintaining product integrity during storage and transportation. Different wrapping materials offer unique protective properties tailored to various environmental exposures, handling conditions, and durability requirements. Here are some commonly used wrapping materials for hose coils, each providing specific advantages:

Stretch Film: Stretch film is a versatile and flexible material ideal for tightly securing hose coils. Its elasticity allows it to conform to the coil’s shape, ensuring a secure hold that minimizes movement and reduces the risk of damage. Stretch film is particularly effective for hoses stored in dusty or lightly exposed environments, as it creates a protective barrier while maintaining accessibility for quick inspection. The film’s stretch properties also help reduce material waste by allowing operators to control tension, making it both cost-effective and efficient for standard protection needs.

Shrink Film: Shrink film offers enhanced security by creating a snug fit around the hose coil when heat is applied. This material is excellent for hose coils exposed to moisture or environmental contaminants, as it creates an airtight seal that guards against humidity, dirt, and potential corrosion. The heat-shrink process tightly encloses the coil, offering additional stability and a higher level of protection for delicate hoses. Shrink film is often preferred for export packaging or storage in high-humidity conditions, where long-term durability and a clean, professional finish are essential.

Polyethylene Film: Known for its durability and tear resistance, polyethylene film is frequently used for heavy-duty, industrial-strength protection. This material can withstand rough handling, making it suitable for hose coils subjected to harsh environments or frequent transportation. Polyethylene’s thicker construction provides a robust barrier that resists punctures and abrasions, ideal for protecting hoses with sharp or abrasive surfaces. Additionally, its waterproof qualities make it a go-to material for industrial applications where water resistance is crucial.

Paper Wrapping: Paper is a simple, cost-effective option used for light protection, often in combination with other materials like stretch or polyethylene film. Paper wraps are typically applied for hoses requiring a basic level of protection against surface scratches and light dust. As a biodegradable material, paper is also environmentally friendly, making it a suitable choice for companies aiming to reduce their environmental impact. Paper wrapping is commonly used for short-term storage or less demanding transport conditions.

Fabric Wrap: Fabric wrapping is a premium option used for delicate or specialty hoses requiring additional protection against scratches, impacts, and other physical damage. Often made from non-woven or woven materials, fabric wraps provide a soft cushioning layer that minimizes direct contact with hard surfaces, reducing the risk of damage. This wrap is also breathable, helping prevent moisture buildup and corrosion, which is especially useful for high-value or custom hose products in sensitive applications.

I'm online now.