The Ultimate Guide to Coil Wrapping Machines for Bearings: Benefits, Types, and Industrial Applications

Coil wrapping machines for bearings come in a range of types, each tailored to different production scales and levels of automation. Selecting the right machine type can enhance operational efficiency, reduce labor requirements, and ensure consistent protective wrapping for bearings. Here’s an overview of the main types:

-

Manual Coil Wrapping Machines: These machines are simple, cost-effective solutions, primarily suited for low-volume operations or facilities with limited packaging needs. Manual machines rely heavily on human intervention; operators load and unload bearings, apply the wrapping material, and guide the wrapping process by hand. While they offer a budget-friendly option for smaller businesses or specialty applications, manual machines require more time and labor, making them less suitable for high-output environments. They are, however, an ideal choice for operations prioritizing flexibility and lower investment.

-

Semi-Automatic Coil Wrapping Machines: Semi-automatic machines provide a balance between manual operation and automation, making them ideal for medium-volume settings. In these machines, operators are responsible for loading and unloading the bearings, while the machine independently handles most of the wrapping process. Wrapping material can be fed manually or automatically, depending on the machine model and operator preference. With automated options for material feeding, semi-automatic machines can reduce operator fatigue and increase wrapping speed compared to fully manual systems, allowing for greater consistency in mid-sized operations. They are especially beneficial for companies that need moderate automation without fully committing to high-capacity equipment.

-

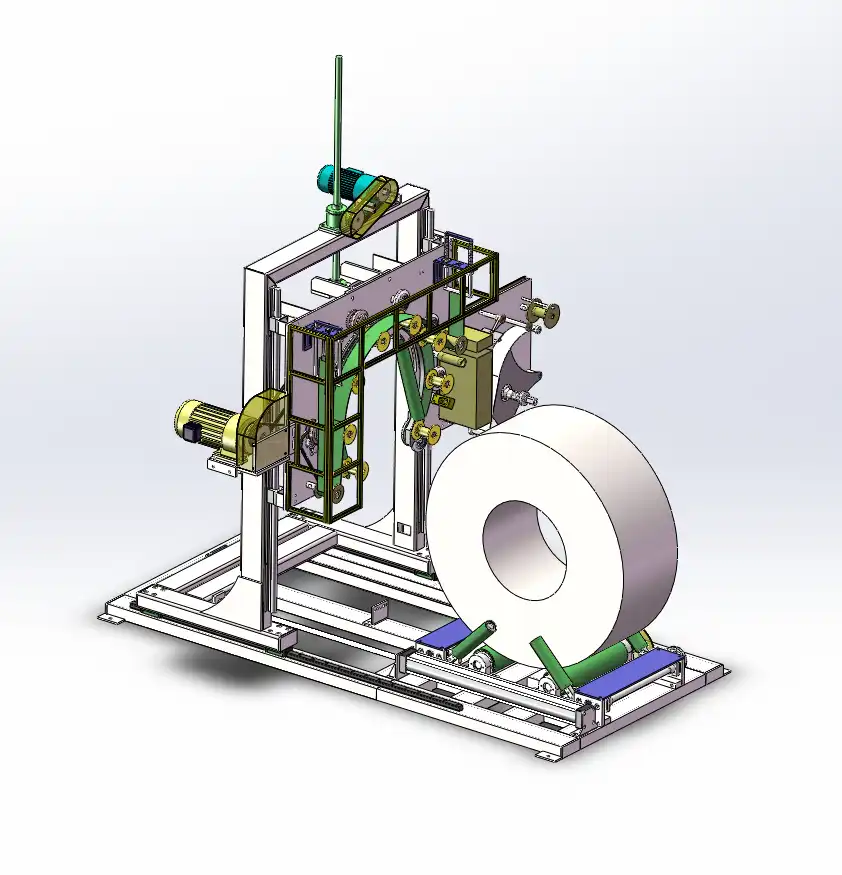

Fully Automatic Coil Wrapping Machines: Designed for high-volume, industrial-scale production, fully automatic machines require minimal human intervention, focusing on efficiency and high throughput. These machines include advanced features like conveyor systems or automated loading devices to load and unload bearings, making them a top choice for industries with large-scale packaging needs. Once a bearing is placed on the machine’s conveyor, it moves through each packaging stage without requiring manual input. The entire process, from material application to final wrap completion, is automated, resulting in consistent, high-quality packaging that’s optimized for high-speed operations. Fully automatic machines also typically feature adjustable controls to handle varying coil sizes and wrapping specifications, allowing for adaptability in fast-paced manufacturing environments.

Selecting the appropriate coil wrapping machine for bearings hinges on balancing production demands, budget, and desired automation level. By matching machine capabilities to operational needs, companies can achieve efficient, reliable, and protective wrapping solutions, enhancing both productivity and the quality of their packaged bearings.

Parameters:

|

Item

|

H02

|

H05

|

H10

|

H20

|

H40

|

H50

|

Power Supply

(V/Hz)

|

AC 380/50

|

Power

(Kw)

|

2.5

|

3.5

|

5.5

|

6.5

|

8.5

|

10

|

Max. Loading

(T)

|

2

|

5

|

10

|

20

|

40

|

50

|

Working Table

(mm)

|

Per Load size

|

Speed

(sec)

|

15-30

|

20-35

|

20-35

|

30-60

|

40-60

|

50-90

|

Machine Weight

(T)

|

1.8

|

2.2

|

2.8

|

3.0

|

3.3

|

3.6

|

Machine size

(mm)

|

Per Load shape & size

|

|

Warrantee

|

2 years

|

|

Driving

|

Hydraulic

|

The Ultimate Guide to Coil Wrapping Machines for Bearings: Benefits, Types, and Industrial Applications

Introduction to Coil Wrapping Machines for Bearings

In industries where precision parts like bearings are essential, protecting these components during storage and transportation is a top priority. Coil wrapping machines specifically designed for bearings provide a solution to these challenges, offering secure, protective wrapping that preserves bearing quality and functionality. These machines are especially crucial in automotive, aerospace, and manufacturing sectors, where component protection directly impacts performance.

Why Bearings Require Specialized Wrapping Solutions

Bearings are precision-engineered components highly susceptible to damage from dust, moisture, and physical impact. Exposure to contaminants or moisture can lead to corrosion, while physical impacts can deform or misalign parts, affecting their functionality. To safeguard bearings, specialized coil wrapping solutions apply a consistent protective layer that prevents damage during handling and transport, ensuring they arrive ready for installation.

How Coil Wrapping Machines Work for Bearings

Coil wrapping machines designed for bearings operate with precision, securely encasing bearing coils in protective film to safeguard against environmental factors and physical damage. The process involves a coordinated movement of the bearing coil and the wrapping material, creating a tight, uniform wrap. Here’s an in-depth look at the components and steps involved:

-

Turntable or Supportive Rollers: The bearing coil is placed on a turntable or supportive roller system that enables 360-degree rotation. As the coil rotates, the wrapping material is applied evenly across its surface. This continuous rotation is crucial for uniform coverage, ensuring all parts of the bearing coil are equally protected without requiring manual repositioning.

-

Packing Material Dispenser: The dispenser holds and applies the protective material—such as stretch film, VCI (Vapor Corrosion Inhibitor) paper, or other wraps—ensuring consistent tension throughout the process. This prevents loose or uneven wrapping, which could compromise the bearing’s protection. The material dispenser often moves along a ring or arm around the bearing coil, allowing it to wrap from all angles as the coil turns.

-

Control System: Advanced control systems allow operators to customize key wrapping parameters, including tension, speed, and type of wrapping material, to suit various bearing sizes and protection needs. This adjustability is especially useful when handling different coil diameters or protective requirements, ensuring that each bearing coil receives the ideal amount of wrap and tension.

This precise wrapping process maintains the cleanliness and integrity of bearings, protecting their sensitive surfaces and prolonging shelf life.

Types of Coil Wrapping Machines for Bearings

There are several types of coil wrapping machines for bearings, each catering to different scales of operation and automation needs:

-

Manual Machines: Simple and cost-effective, suitable for low-volume operations.

-

Semi-Automatic Machines: These require some manual input but handle most of the wrapping process independently, making them ideal for mid-volume settings.

-

Fully Automatic Machines: Designed for high-volume production, requiring minimal human intervention. These machines are best suited for industries with large-scale bearing packaging needs.

The choice between Horizontal and Vertical Wrapping Machines often depends on space constraints and the dimensions of the bearing coils. Horizontal machines are commonly used for larger items, while vertical machines are more suitable for compact or smaller bearings.

Special Features of Coil Wrapping Machines for Bearings

Coil wrapping machines for bearings often include specialized features tailored to protect sensitive components:

-

Precision Control: Maintains consistent wrap tension, essential for preventing loose wrapping that can allow contaminants to enter.

-

Compact Design: Many models are designed to fit in limited spaces, ideal for facilities handling smaller bearings.

-

Customizable Settings: Adjustable speed, wrap tension, and film compatibility ensure these machines can handle a variety of bearing sizes and protection requirements.

These features make bearing wrapping machines versatile and efficient in both small and large operations.

Benefits of Using Coil Wrapping Machines for Bearings

Investing in coil wrapping machines for bearings offers several key advantages:

-

Protection Against Corrosion: Wrapping prevents exposure to air and moisture, reducing the risk of rust and corrosion.

-

Dust and Contaminant Shielding: Keeps bearings free from dirt, dust, and other contaminants that can interfere with performance.

-

Efficiency and Consistency: Automated machines wrap bearings quickly and uniformly, saving labor costs and reducing the potential for human error.

-

Enhanced Product Presentation: Neatly wrapped bearings are more appealing to customers and can improve brand perception.

With these advantages, bearing wrapping machines help ensure quality and enhance operational efficiency, making them valuable assets for companies in the industry.

Automated Wrapping Machines for High-Volume Bearing Packaging

Automation in bearing wrapping allows companies to meet high production demands without compromising quality. Automated machines can be programmed to wrap different sizes and shapes of bearings, allowing for quick adaptation between different product lines. By eliminating much of the manual labor, these machines also reduce the risk of injury and significantly cut down packaging time, making them an essential part of high-volume bearing production lines.

Selecting the Right Wrapping Material for Bearings

Choosing the appropriate wrapping material is essential for effective bearing protection. Common materials include:

-

Stretch Film: Flexible and strong, ideal for wrapping bearings to secure them against dust and dirt.

-

Shrink Film: Conforms tightly to the bearing, providing additional protection against moisture.

-

Polyethylene: Known for its durability, polyethylene film is resistant to punctures and tears, ensuring that bearings remain securely wrapped.

Each material offers unique benefits, so companies should consider factors like storage conditions, transport distance, and climate when selecting the right option.

FAQs

-

What is the best wrapping material for bearings?

-

Stretch film and shrink wrap are commonly used for bearing protection, offering flexibility and resistance to environmental factors.

-

Can a coil wrapping machine handle various bearing sizes?

-

Yes, many machines are adjustable and can accommodate different sizes, making them versatile for various bearing dimensions.

-

How often should bearing coil wrapping machines be maintained?

-

Daily checks are recommended, with more thorough inspections weekly and monthly to ensure peak performance.

-

What industries most benefit from bearing wrapping machines?

-

Automotive, aerospace, and industrial manufacturing sectors benefit significantly from these machines due to the need for precision bearing protection.

-

Are automated wrapping machines cost-effective for bearings?

-

Yes, automation reduces labor costs, improves wrapping consistency, and minimizes the risk of damage, making it a cost-effective choice for high-volume operations.