+ Machines

FHOPE pallet inverter series

FHOPE has been devoted to pallet chagning machineries for over a decade. The application of the pallet changing machine is in the warehouse company, food factory and logistics... By inverting the pallet loads 90-180°, it is easy to replace the broken pallet or changing the pallet for keeping it in house. The machine is able lower the labor strength and efficiency the operation so that for reducing labour costs. For logistic companies, the equipment is use to help resolution the pallet loading and distribution per different order.

Our team provide two types drivenhydraulic and motor gear. We have made several types with specified designs, each machine can be suitable for specific industries, such as frozen food industry, pharmaceutical enterprises, beverages, electronics...For small business, we also have floor level pallet inverter which doesn't have the need for equipement such as forklift. Other demand, we also would like to know and make the best solution to fit the very special situation.

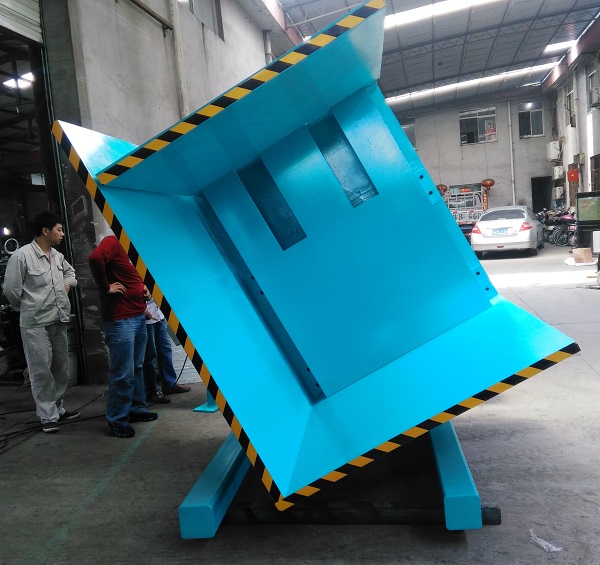

Single clamper pallet inverter

-

Single clamper moves down from the top point

-

Large range for different sized pallets

-

Heavy load capacity is able to customize

-

Machine is stationary and reliable

-

Simplified operation panel with fewer buttons, convenient but functional

-

Easy maintenance and trouble shooting

-

Safety guard is optional to choose

-

More customization is welcome

Dual clamper pallet inverter

-

Double clampers clamping from both up and down directions

-

Faster clamping speed and more balanced turnover position

-

Large range for different sized pallets

-

Maximum capacity depends on cutomer’s needs

-

Remote switch is used, the whole operation can be down by just a forklift driver

-

Multi-style, both mechanical and hydraulic types are designed to fit client’s actual situation

-

Trouble shooting and maintenance are easy for non-skilled workers

-

Other customization are allowed to make

Ground loading pallet inverter

-

Dual platen clamping and centralizing the pallet and goods

-

Sensors are able to attached to stop clamping automatically, avoid damage to goods

-

Floor level design for loading with pallet truck/jack and forklift

-

More time are reduced for clamping and capacity grows

-

No limit on pallet sizes and weights

-

Smooth and stablized strokes

-

Easy operation, both local and remote control are chooseable

-

Fence is attached for work floor safety

-

Specified functions and designs are acceptable

Ramp loading pallet inverter

-

Two clampers clamping from top and bottom sides

-

Low level design with ramp attached for loading with pallet truck or pallet jack

-

Mechanical inverter and hydraulic inverter

-

No shaking or vibration when machine is turning over

-

Heavy load capacity is able to customize

-

Machine is stationary and reliable

-

Romote and local control are free to switch, easy procedure to continue

-

Malfunction is rare to see, fewer wearing parts need to replace

-

Protective shield and fence are included

-

Suitable equipment for industries such as pharmaceutical manufacturers

Online pallet inverter

-

Rollers on the clamper for automatic loading

-

Automatic pallet holding after machine turnover

-

Reserved forklift groove for uploading the goods

-

Machine works for both large and small pallets

-

Different loads are covered

-

Stationary movement, a dependable machinery for large warehouse and factory line

-

Simplified operation panel with fewer buttons, convenient but functional

-

Less defects and responsible aftersales service

-

Customization is emphasized and needed for this pallet inverter

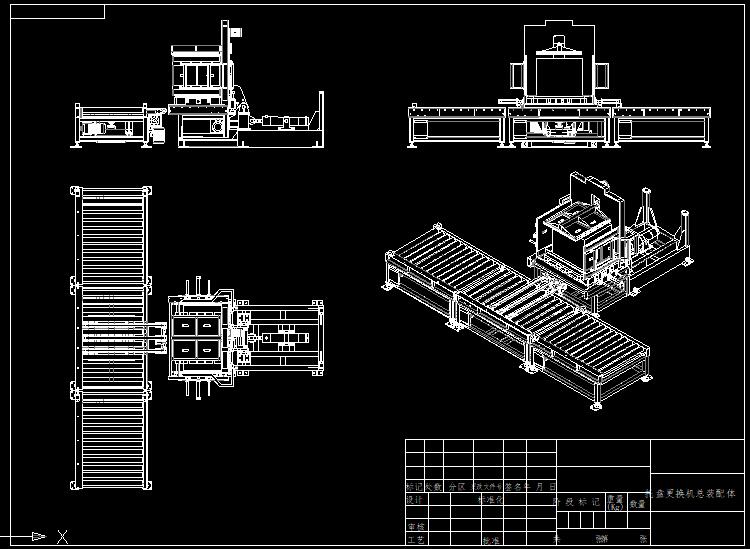

Custom pallet inverter

-

Customized solution for automation purpose

-

Rollers on the machine for conveying

-

Suitable for medium size pallet with goods loaded on

-

Able to connect with production line or packing line

-

Reduce labour cost and expand capacity

-

Photocell are adopted for detecting the approaching of goods

-

Separated workfloor, safe and protected

-

High quality equipment and excellent aftersales service

By pallet changer, it can make pallet chagning faster and easier for you to replace loaded trays or damaged trays. The pallet changing equipments can change the tray without completely taking or reloading the load. It is a good way to preserve the integrity of goods without need to changing the pallet by re-palletizing, and it don't need put the pallet back to the ground for exchange. The use of pallet changer includes the load transfer from wood to sanitary internal pallet, and the output load is converted into transportation or one-way pallet, and the load that remains as it is after the transfer is processed is the measurement standard.

Each industrial pallet inverter has been well designing manufactured per feedback from the end user. And our customre can get two year warranty benefits. For the pallet inverters with competitive prices, we always have the standard mold in stock and can deliver them from our factory. As an important part of material handling in the factory, the pallet inverter reduce the operating costs of all key aspects of business execution, including production, storage, retrieval and distribution. The machine had been exported to more than 50 countries, Pallet inverter by a part of the FHOPE handling solutions provides for pallet load turning in the highest quality, which can load all types of goods from bags and buckets to boxes, cartons and cans. With long using life and years of service, our pallet inverter machine can help customers reduce a lot of costs.

Features

1.Protect the package and eliminate damage

The

key feature to using A tray pallet inverter is for improve the

operation safety and helping to reduce the cost in pallet handling that

is happlening everyday in the some factory. Comparing to the manually

pallet chaning with tool, the machine work in pallet "exchanging" is

more efficiency. Fhope developed the conveyor and robot system is is

able checking and reading the load for automatic distribution and

automatic pallet changing and pallet restocking. Main features of the

equipment include:

1. Easy to be cooperated and connection by forklift, forkman in floor level

2. Different ways for pallet loading and convenient for forklift transportation and un-loading

3. Reverse or transfer different pallet load types by height adjustment from 600mm-2200mm

4. Safety handrail protection and higher level light bean protection is available.

5. Maintenance the stability of the load in pallet load tiltering

6. Holding the balance valve and maintain the right pressure that designed per different goods.

7. Feet block photo eyes to prevent potential pinch points.

Files Download