Click to Chat

I'm online now.

Fhopepack Innovation

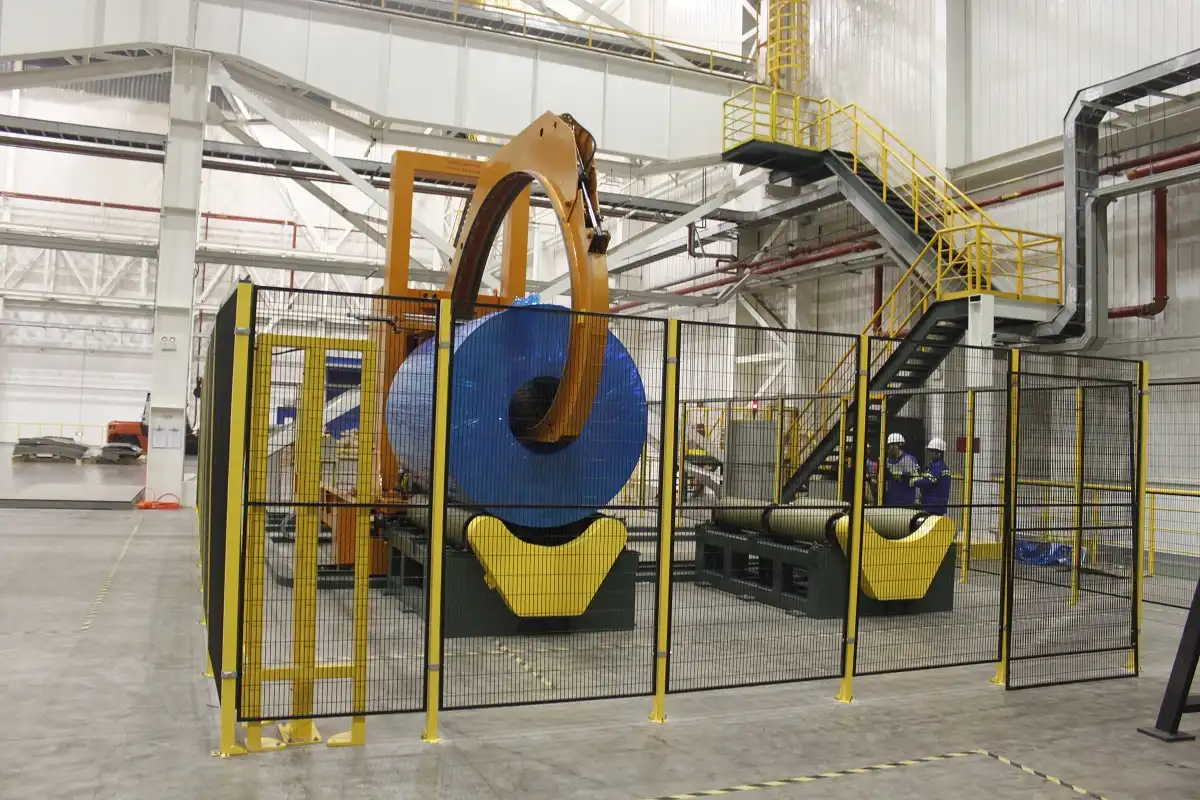

The Coil Wrapping Machine for Aluminum Coil delivers reliable, high-quality wrapping for aluminum coils, enhancing product protection and stability during transit. This advanced machine optimizes the wrapping process with adjustable settings for various coil sizes, offering durable, uniform packaging that reduces handling risks and ensures safe delivery.

Coil wrapping machines for aluminum coils are designed to provide protection and durability during storage and transport, and they come in different configurations based on production volume, coil size, and automation requirements. Here’s an overview of the primary types of aluminum coil wrapping machines, each suited to specific operational needs:

Rotary Arm Wrapping Machines: Rotary arm wrapping machines are ideal for aluminum coils that are stored and transported on pallets in an “eye to sky” orientation, where the center of the coil faces upward. In these machines, a rotary arm moves around the stationary coil, applying film in a consistent and stable wrap. This setup is particularly useful for large, heavy coils that need a secure wrap without being rotated. By holding the coil steady on a pallet, rotary arm machines reduce the risk of coil deformation or damage and allow easy handling with forklifts, making them suitable for high-volume applications that require robust protection.

Semi-Automatic Coil Wrapping Machines: Semi-automatic machines provide a balance between manual control and automation, making them ideal for mid-volume production facilities. These machines require some initial setup, such as loading the coil and securing the film, but then automate the wrapping process itself. This setup is beneficial for companies that need efficiency without fully automating their process. Semi-automatic machines offer reliable wrapping with precise film tension, ensuring an even wrap across the aluminum coil without over-stretching or damaging the material. This type is cost-effective and flexible, accommodating mid-scale production needs while providing a high level of operator control.

Film Covering and Box Packing Machines: For aluminum coils requiring additional layers of protection, film covering and box packing machines provide an integrated solution. These machines wrap the coil in protective film, typically with vapor corrosion inhibitor (VCI) or stretch film, and then package it in a box for maximum protection. This method is commonly used for coils that are sensitive to environmental exposure or require high protection levels during transport. The box packing option also adds an extra layer of impact resistance, making it ideal for long-haul transportation or export packaging.

Automatic Master Coil Wrappers: Automatic master coil wrappers are designed for high-volume, large-diameter aluminum coils and require minimal human intervention. These machines are equipped with advanced automation, including conveyor systems for coil infeeding and out-feeding, film length calculation, and automatic cutting, which speeds up the wrapping process and reduces labor costs. The automatic master coil wrapper can handle large coil sizes and ensures consistent, high-quality wraps, making it suitable for facilities with high output demands. These machines are often equipped with control panels that allow operators to set parameters for wrap tension, film type, and wrapping speed, ensuring optimal wrapping for each specific coil size and type.

Horizontal Wrapping Machines: Horizontal wrapping machines are frequently used for large-diameter aluminum coils. The horizontal configuration allows coils to be loaded and wrapped while lying flat, making it easier to handle large, heavy coils. This type of machine often includes a rotating ring that moves along the coil’s circumference, applying film with consistent tension. Horizontal wrapping machines are beneficial in high-output facilities where large coils are regularly handled, as they enable efficient wrapping with added stability for bulky or weighty coils.

Vertical Wrapping Machines: Vertical wrapping machines are more compact and suitable for smaller to mid-sized aluminum coils. With a smaller footprint, these machines are ideal for facilities with limited space or budget constraints. Vertical wrapping machines hold the coil in an upright position, which reduces floor space requirements and allows for easy loading and unloading. They’re ideal for companies with medium to low production volumes that still require reliable, consistent wrapping for aluminum coils. Vertical machines are also a cost-effective solution for businesses looking to maximize efficiency in tighter spaces without sacrificing wrapping quality.

|

Model |

Voltage (V/Hz) |

Power (KW) |

Coil ID (mm) |

Coil OD (mm) |

Coil Width (mm) |

Coil Weight (Kg) |

Packing Material |

|

|

FPW-300 |

customized

|

1.5 |

508-610 |

600-1200 |

100-300 |

20-1000 |

PVC/LLDPE/PE/PAPER/HDPE |

|

|

FPS-400 |

customized |

4.0 |

508-610 |

800-1400 |

100-400 |

100-2000 |

PVC/LLDPE/PE/PAPER/HDPE |

|

|

FPS-500 |

customizable |

2.0 |

508-610 |

700-1400 |

200-500 |

100-1000 |

PVC/LLDPE/PE/PAPER/HDPE |

|

|

FPS-600 |

customizable |

7.5 |

700-1100 |

1000-1500 |

200-600 |

200-2000 |

Crepe paper/plastic knit tape |

|

|

FPS-800 |

customizable |

7.5 |

508 |

800-1400 |

400-800 |

200-1000 |

PVC/LLDPE/PE/PAPER/HDPE |

|

|

FPCA-1000 |

customizable |

4.5 |

508-610 |

700-1600 |

20-400 |

100-2000 |

PVC/LLDPE/PE/PAPER/HDPE |

|

In industries where aluminum coils are essential, efficient handling and packaging are crucial. Coil wrapping machines tailored for aluminum coils offer comprehensive protection, keeping coils free from environmental damage and ensuring they arrive in pristine condition. These machines streamline the packaging process, providing a secure, consistent wrap that safeguards the coils during storage and transit. In this guide, we’ll explore the advantages, functions, and best practices of using coil wrapping machines for aluminum coils.

Aluminum coils, though durable, are particularly susceptible to environmental and physical damage that can compromise their appearance, structural integrity, and overall performance. The soft and malleable nature of aluminum makes it more prone to scratches, dents, and deformation if not properly protected. To maintain the quality of these coils, specialized wrapping solutions are essential, especially for those transported over long distances or exposed to extreme conditions.

One of the primary vulnerabilities of aluminum is its sensitivity to moisture and humidity. Prolonged exposure to these elements can lead to oxidation and corrosion, which is particularly problematic for coils shipped via sea freight where the salt-laden air accelerates corrosion. A protective wrapping layer serves as a moisture barrier, shielding aluminum coils from these harsh conditions and ensuring they reach their destination without deterioration.

Dust and other airborne contaminants also pose a risk to aluminum, as they can cling to the coil surface, affecting its appearance and potentially impacting processes like finishing, coating, or fabrication. Wrapping machines for aluminum coils are designed to tightly apply layers of protective film, sealing out dust and debris that could compromise the coil’s surface quality.

Furthermore, the handling and movement of large aluminum coils can easily result in scratches or dents if they’re unprotected. These damages not only affect aesthetics but can also impact performance if the coil is used in applications where precision and uniformity are critical. Coil wrapping machines provide a secure layer of protection that minimizes the risk of damage during handling, preserving the coil’s pristine surface and ensuring it remains in optimal condition.

The specialized wrapping process also enhances efficiency. Manual wrapping is not only slow but can be hazardous given the size and weight of aluminum coils. Wrapping machines automate this process, applying consistent tension and layers that offer reliable, high-quality protection without the labor risks associated with manual handling. For facilities that handle high volumes of aluminum coils, automated wrapping solutions significantly reduce both time and labor costs, while enhancing safety standards.

High-quality wrapping machines for aluminum coils are equipped with features that enhance protection and adaptability:

These features make wrapping machines adaptable to various coil sizes and production requirements, ensuring a consistent, high-quality wrap each time.

Selecting the right coil wrapping machine for aluminum coils is essential for ensuring efficient operation, durability, and optimal protection. Here are some critical factors to keep in mind:

Size Compatibility and Weight Capacity: Aluminum coils come in a range of sizes and weights, so it’s crucial to select a machine that can handle the specific dimensions and weight of your coils. Some machines are designed to wrap smaller coils, while others are built for heavy-duty, large-diameter aluminum coils. Ensuring the machine can accommodate your largest and heaviest coils not only safeguards against potential operational disruptions but also maintains the quality of the wrapping. Adjustable coil holders and tension controls can provide added flexibility for facilities that work with varying coil sizes.

Level of Automation: The automation level of the wrapping machine should match the production volume and workflow of the facility. For high-volume production environments, fully automated wrapping machines are ideal, as they streamline the entire process—from coil loading to wrapping, cutting, and sealing—requiring minimal human intervention. These systems maximize productivity, reduce labor costs, and ensure consistent wrapping quality. However, for smaller facilities with moderate production needs, semi-automatic machines may be more cost-effective. Semi-automatic machines offer automation in the wrapping process while allowing manual input for setup, providing a good balance between control and efficiency.

Material Flexibility: Different wrapping materials offer varying levels of protection against dust, moisture, and physical damage. A versatile coil wrapping machine should be compatible with multiple types of wrapping materials, such as stretch film, VCI (Vapor Corrosion Inhibitor) film, and polyethylene, to meet the diverse protection needs of aluminum coils. This flexibility is especially important for facilities that serve clients with specific protection requirements or those shipping coils across different climates. Choosing a machine that can accommodate these materials ensures the right level of protection for each coil, preserving quality throughout transportation and storage.

Protection Level Requirements: Aluminum is particularly vulnerable to dust, moisture, and scratches, especially during long-distance transport or sea shipping. Some machines offer advanced protection features, such as multi-layer wrapping, which creates an extra barrier for coils subject to extreme conditions. For applications requiring higher protection standards, look for machines that provide adjustable wrap thickness or allow for multiple layers of film. Ensuring that your machine can meet specific protection standards helps maintain the structural integrity and appearance of the aluminum coils, reducing the likelihood of corrosion or surface damage.

Customization and Special Requirements: Customer specifications may vary widely, with some requiring branded wrapping, extra protective layers, or specific labeling. Selecting a machine that allows for customization, such as automated logo printing or label application, can enhance customer satisfaction by meeting these requirements directly in the wrapping process. Additionally, features like adjustable film tension, varying speeds, and precise film cutters ensure that you can tailor the wrapping to meet both your and your customer’s standards without adding time or labor.

I'm online now.