Click to Chat

I'm online now.

Fhopepack Innovation

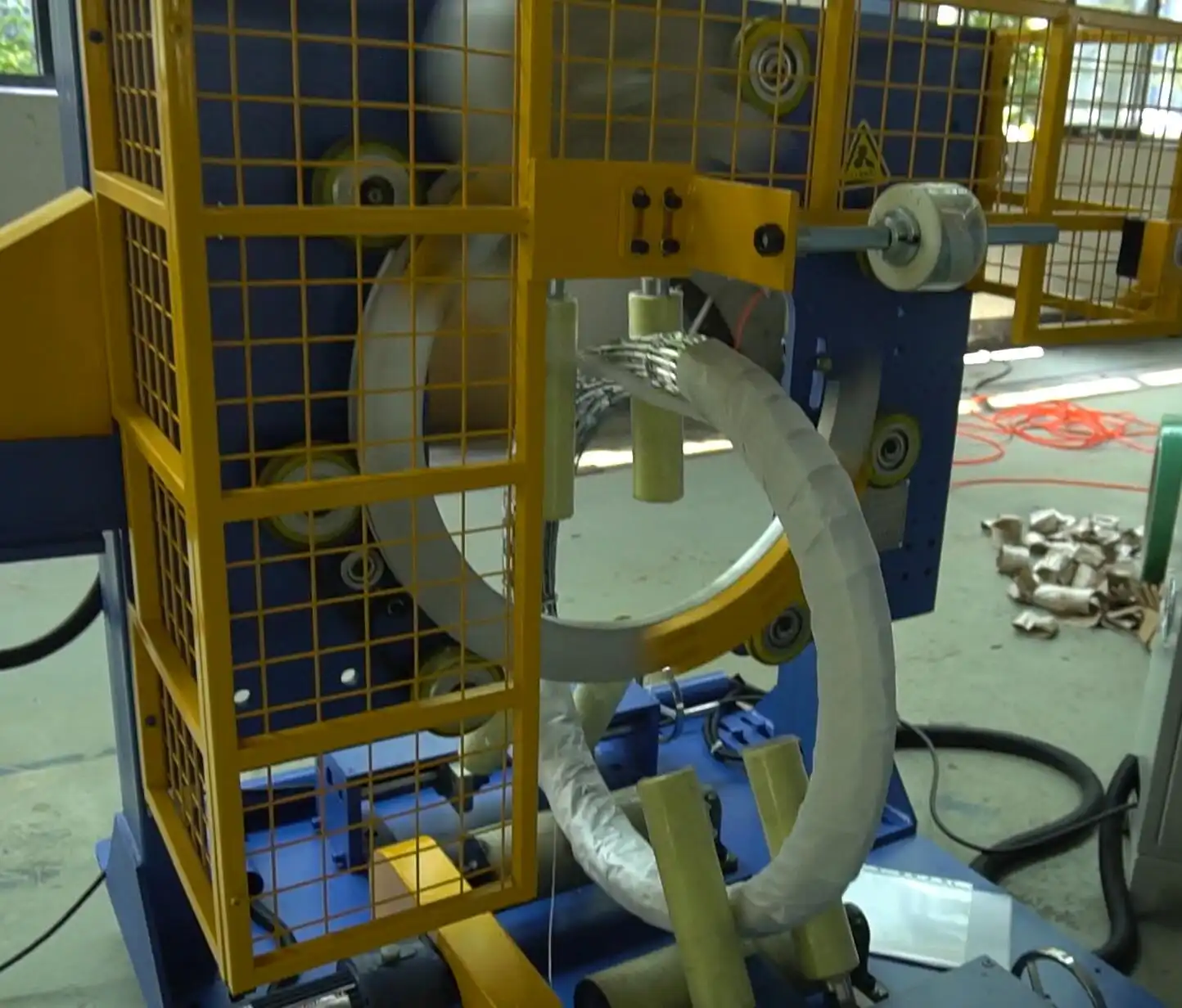

All of the machines provided by Fhope conform to CE guidelines and are designed using the latest technology and design criteria for industrial use. Fhope offers a wide range of packaging solutions for coil products, providing efficient and effective wrapping and packing solutions that ensure the safety and protection of the products during transportation and storage.

1) Benefit:

The machine was special made for razor wire coil packing that is able cover the stretch film inside layer. And wrapping the paper, woven outside layer for protecting the package.

Ring level adjustment by motor

Logo tape tapping device

4) Technical parameter:

|

Machine Model |

FPW300-W |

|

Object weight |

10-100kg |

|

Package width |

200-300mm OD = 700-950 mm, ID = 450-700 mm OD-ID<300mm |

|

Roller Speed |

2-4m/min |

|

Wrapping speed |

20-35sec/pcs |

|

Rotating speed |

40-100r/min |

|

Overlap scope |

20%-90% |

|

Power output |

app. 1.5kw |

|

Power voltage |

380v/50Hz, 3Phase 5 wires |

|

Packing material |

Crepe paper / knit belt / compound paper / HDPE ID: 55mm OD: 300-450mm Width:70- 90mm

|

I'm online now.