Many people have a question, what is the min. width fo the packing material aviable for my coil packing by coil wrapping machine?

Following is the anser: Choosing the Max.width of the packing material per Min.ID of the coil.

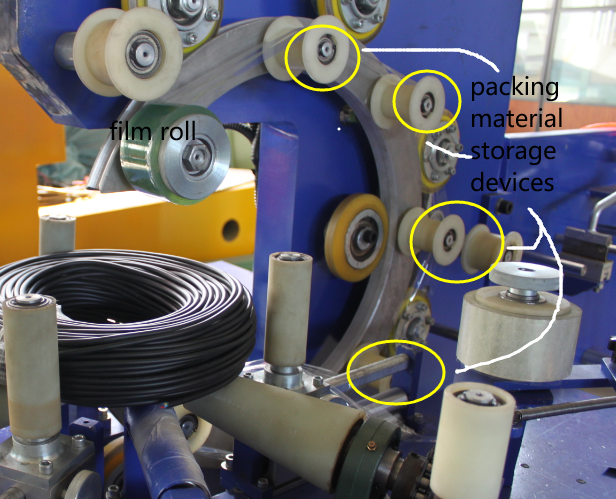

There are fixed size material storage devices and film roll in the ring. For coil packing with eye through wrapping, the packing machine must to be designed per coil Min.ID so that the ring and packing material is able to be crossed the coil ID safely.

If the Min.ID is 120mm, the availabe Max. width is 40mm. By this way no matter coil ID 150mm or 270mm, all must following the design per Min.ID 120mm. Same principle, if the Min. ID 150mm, the packing machine will be designed per 150mm .

• The packing material width mainly depends on the minimum coil ID and the packing ring design. For a given minimum ID, there is an optimum range of film widths that can safely pass through the coil center.

• Wider film requires larger diameter packing rings and additional guide components to stabilize the film during wrapping. This increases the machine’s cost and complexity.

• Narrower film allows for a more compact packing ring design since less space is needed to accommodate the film width. Hence machines are designed for an optimum film width based on the minimum coil ID.

• However, some flexibility in film width – usually up to 10-20mm wider – can often be accommodated to some extent by adjusting the packing ring and film guide arms. This provides more material options.

• The packing ring and film guides must be properly lubricated to allow wider film to pass through the coil center without rubbing or snagging.

• Wider packing material is only recommended for coil IDs that are significantly larger than the machine’s minimum rated ID. Otherwise there is a risk of film jamming inside smaller coils.

• When choosing a coil wrapping machine, specifying the minimum and maximum coil IDs that need to be handled will allow manufacturers to recommend the proper packing material width for best performance.

• In general, a packing material width around 30%-50% of the minimum coil ID tends to work well for most coil wrapping machines. But the maximum recommended width should be confirmed based on the specific machine design.

The principle is making the packing material getting through the Min.ID and than using it works for the bigger size.

For more information for the coil packign machine:

Contact us: info@fhopepack.com