Automatic wire coiler: a kind of high speed wire winding and strapping machine

1)

Application:

The automatic steel wire winding and strapping machine for automatic wire coiling & strapping that conforms to all CE guidelines. It uses the latest technology and new proposals for steel wire industrial use.

FHOPE offers turnkey solutions for the steel wire industry to achieve full automation after production. Our commitment to the industry has resulted in the development of innovative, cost efficient products that address problems in man power shortage, irregular winding coil.

Our sales, equipment service, customer service and engineering departments can help you design the optimum protective packaging system for your application.

2)

Technical Features:

n Suitable for wire diameter: Customized

n Maximum speed: 200-800m/min

n center height of machine: it is 1000mm from the ground

n Supply voltage: 380/440 Vca, 60Hz

n Coil Info: Customized

n Speed per hour: 40/hour (double head), 20/hour (one head)

3)

Main technology parameter and components

A.

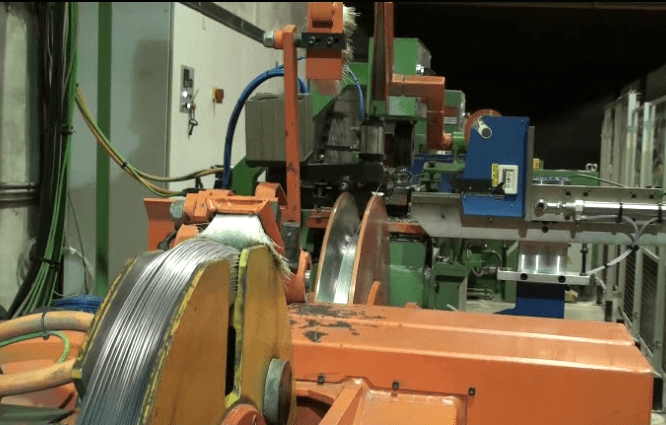

Vertical tension wire accumulator

n Frame: assembled and welded with Steel plate

n Power: reducing-speed motor

n It is able adjusting the tension for coiling

n wire-accumulating length:5m-20m

n tension adjustment: tension can be adjusted by tension control-cabinet DC-24V power.the vehicle can be controlled in both ways .the meter indicates tension.synchronous device can automatically control the take-up speed to avoid overstretch or breaking on the wire.

n safe device: the limit switch are laid at the front and back end.

n The machine stops at the same time when wire breaking .

n Anti-collision:compression spring

B.

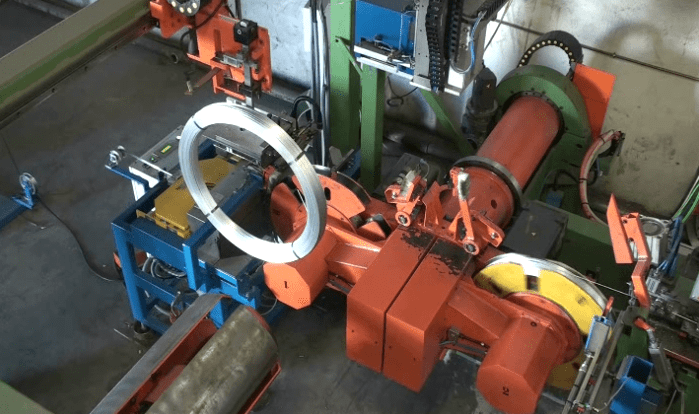

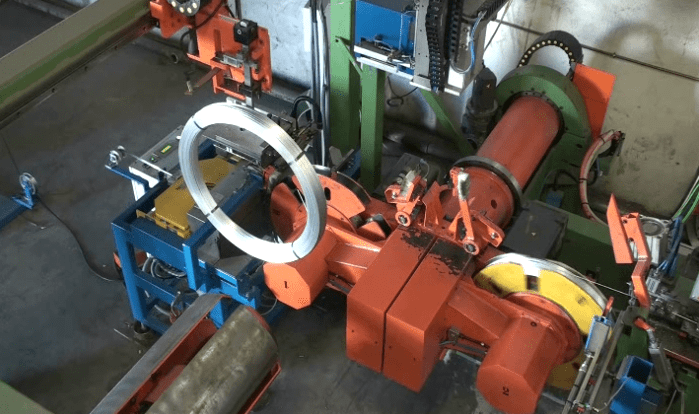

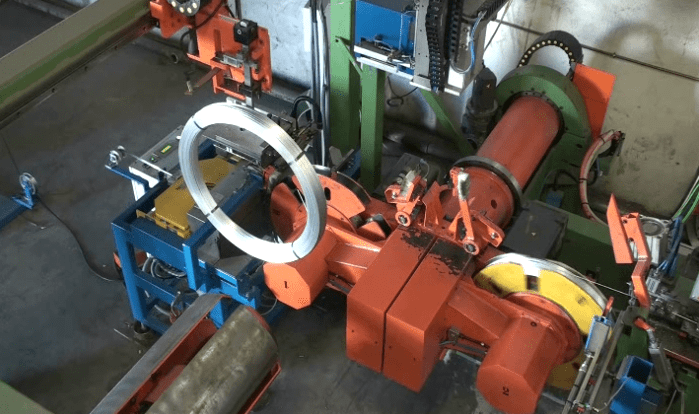

Automatic Coiling Machine

Feature:

n Two coiling heads for continue wire winding

n Automatic wire feeding, winding and cutting.

n PLC can store wire reel specification, when need change wire reel specification, only need to read stored specifications.

n Automatic alarm function, automatic send signal when wrong come out

n product convey:clamp wire

n overlength:unit:0.01m, automatic reduce speed when forecast

n servo motor control traverse, linkage with shake-bobbin machine

n switch and meter on operation panel:touch screen,speed-adjust button, emergent switch

Machine details:

1: Length meter counter:

with up and down adjustable encoder wheel, the machine provides the precise count length to centimeter. The up and down wheel are made with sprayed aluminum alloy material pr ceramic and hardness procession. The down wheel is covered with strong PU to prevent wire deforming and damage. The signle drection bearing design makes non wire inversion.

2. Winder head:

Automatic wire infeeding for widnding. The winder with servo controlled dispenser for wire coil shape control. The winder head is able start and stop precisily for winding and strapping position. automatically stop take-up when reach pre-set length, then coiling head opening

3 .traverse:

It is for shifting the winder head Computer control traverse, servo motor drives,

4.portal cutter:

Portal cutter,automatic cutting wire when wire reel reach pre-set length. Cutter is made with special steel material and vacuum heating processed, higher hardness and longer lifetime

5. control system:

HMI and PLC operation. All winding data can be setting on it. such as wire reel length, wire coil width, error alarm , speed adjustment. Also shows the IOT for easy monitoring. The operator can change wire reel length , wire diameter , wire speed during machine running.

C.

Automatic coil strapping machine

The strapping machine dispenses, tightens and seals polypropylene while coil in strapping position. The machine strap and joins the ends automatically with adjustable tensions by secure heat weld. The motor automatically gets switched off while strap is inserted.

Features:

n Wire coil ID through strapping.

n Program control for BOTH coiling and automatic strapping.

n Automatic positioning for different coils.

n Tension adjustable for different wire coil.

n Connects with coiling machine.

n Taper roll with lifting and downing function.

n 3-6 places strapping.

Technical date:

Strap width

|

10mm

|

Strap thickness

|

0,8 mm

|

Type of strap

|

PP

|

Strap quality

|

Smooth /High quality polyester strap

|

Type of joint

|

By friction - vibration

|

Joint location

|

The strapping is performed in the front part of the wire coil.

|

Joint efficiency

|

Approx. 75-80% of the breaking load of the strap (mentioned quality).

|

Machine details:

1: Strapping Head:

The strapping machine with high sucessful rate which designed to perform the radial (ID) strapping of the coils with PP belt. After coil position, it performing all the strapping process in automatic mode. The automatic strapping machine will be placed on the wire coiling machine. The strapping machine will be positioned in a fixed position on the coordinate +0-0.The strap dispenser and accumulator will be placed at a fix position.

2. Strap belt accumulator:

This device includes the PP belt pay-off unwinding device for the purpose of accumulating the PP belt . There are movable wheels will feedback the signal of belt feeding speed to pay-off stand,

D.

Automatic wire coil unloading machine

This is a automatic device for automatic take off the strapped wire from the coiling head.And place the wire coil in to gathering position.

Technical data:

n Automatic program controlled.

n Automatic position action per setting

n Crane and guide rail for smooth running.