Click to Chat

I'm online now.

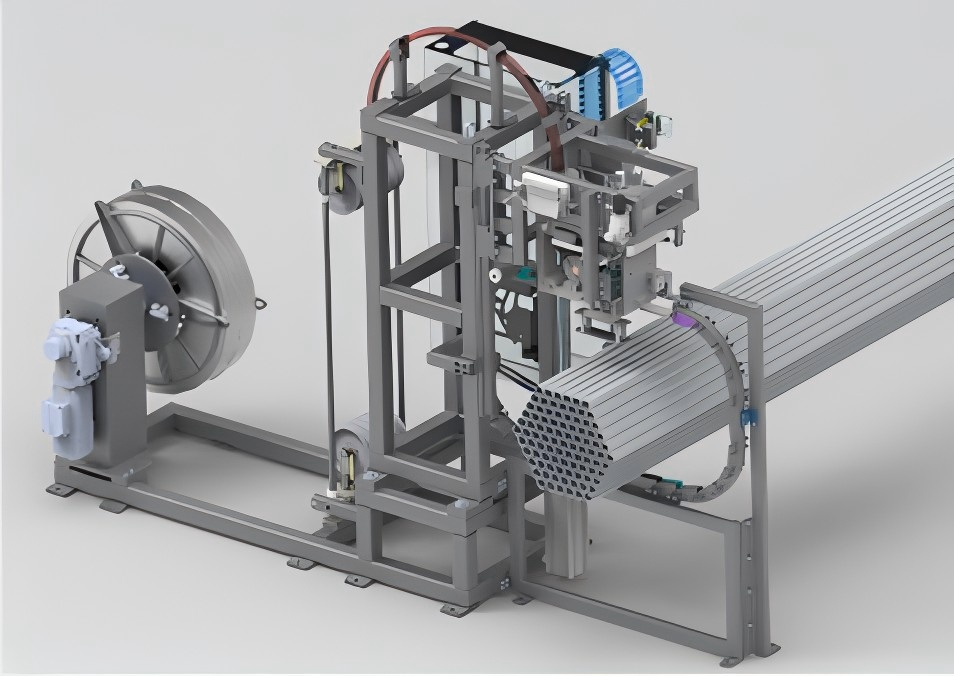

Our Automatic Rod Packing Line and Automatic Bar Packing Line solutions are designed to streamline and enhance your packaging process with precision and efficiency. These cutting-edge systems integrate advanced equipment, including Bar Wrapping Machines, Bar Strapping Machines, and Rod Bundle Making Machines, to handle diverse packaging requirements seamlessly.

Engineered for versatility, these solutions are tailored to accommodate various bar and rod dimensions, ensuring secure packaging for transport and storage. The line is fully customizable, allowing you to meet unique operational needs and industry standards.

By automating key tasks, these systems reduce manual labor, improve productivity, and enhance packaging consistency while minimizing material waste. Whether you're handling large-scale production or specialized packaging demands, our Automatic Rod and Bar Packing Line solutions deliver unmatched reliability, efficiency, and adaptability for your business.

In-House Design

We create custom working table poer your mold specific.

Self-Manufacturing

Our own factory production ensures quality control at every step.

After-Sales Support

We provide after service directly from our expert team in 24 hour.

An Automatic Rod Bundling Machine streamlines the bundling process for rods, ensuring precise alignment and secure packaging. Designed for efficiency, it mini...

The Automatic Rod Packing Machine streamlines rod packaging with speed and precision. It reduces manual labor, ensures secure wrapping, and boosts productivity, m...

The Automatic Rod Strapping Machine offers fast, secure strapping for rods, improving packaging efficiency and reliability. Its robust design, easy operation, and...

The Customized Rod Packing System provides flexible and efficient solutions for rod packaging. With tailored designs, it ensures secure wrapping, reduces labor, a...

Need help with special rods packing solution or customized design per your specification? Searching for the latest coil wrapper? Get support from us...

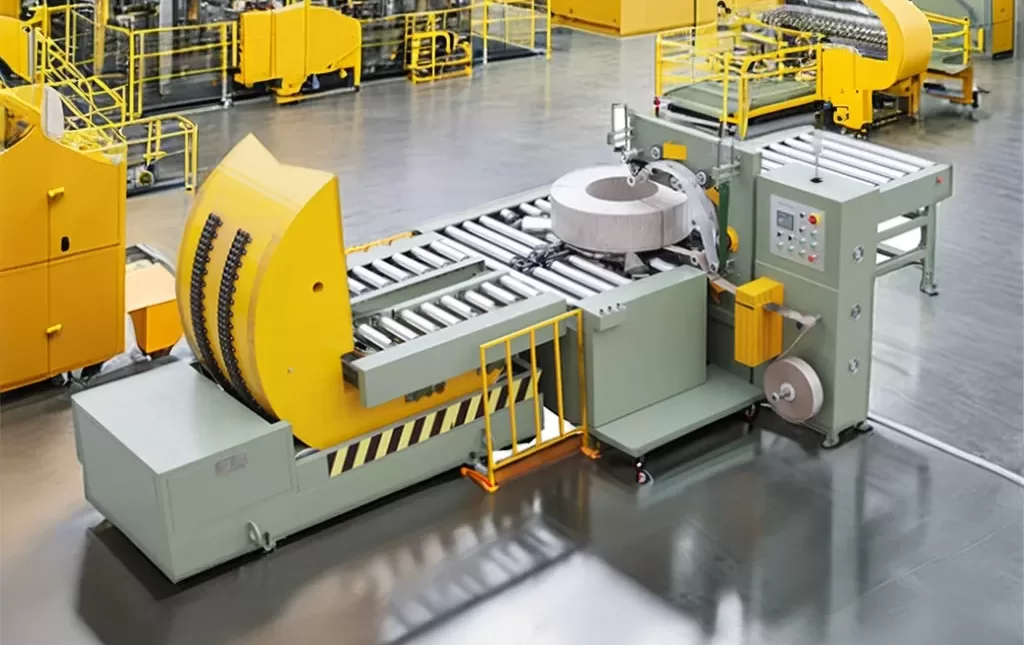

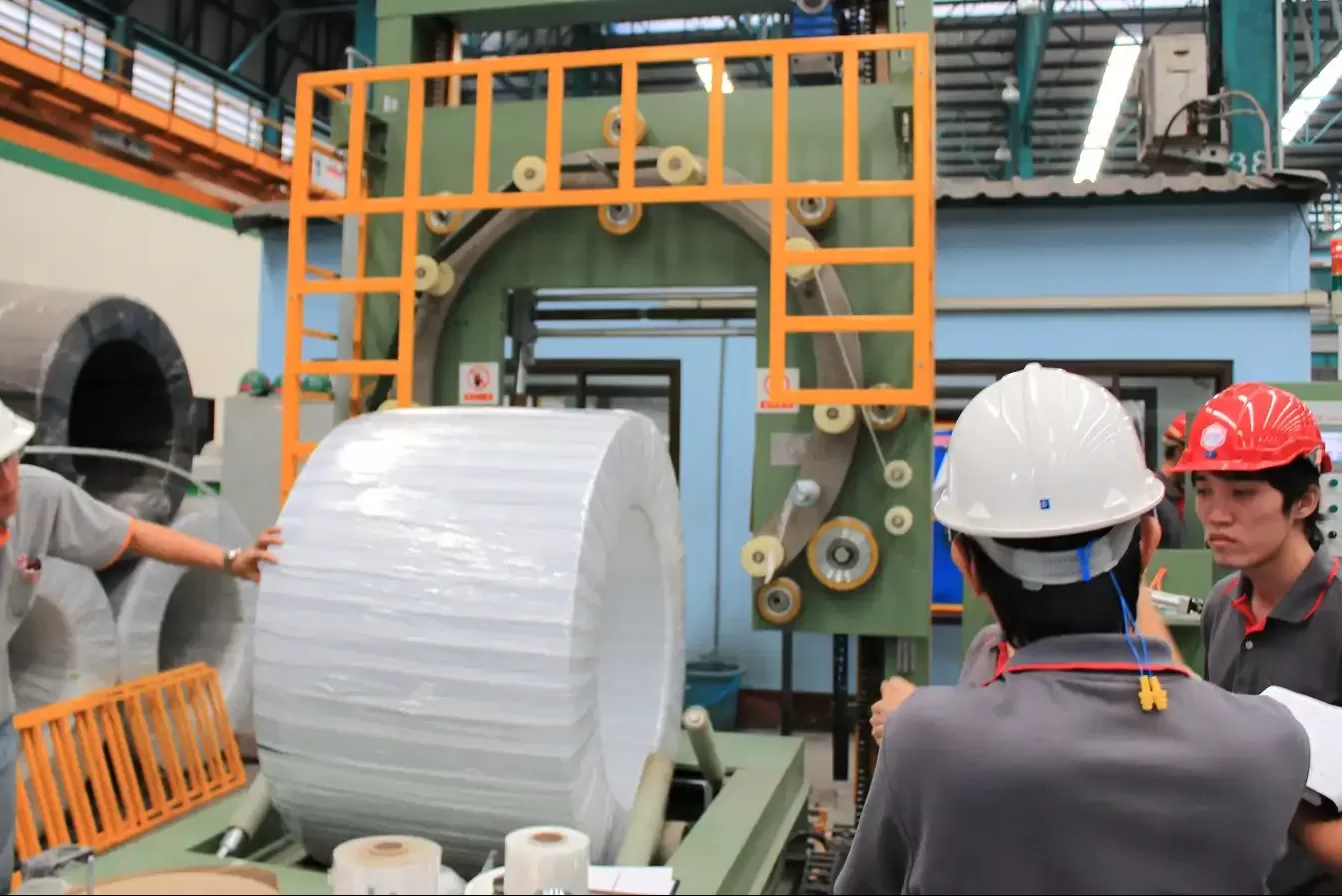

Selecting a coil wrapping machine tailored to your handling method is crucial for optimizing efficiency and ensuring seamless operations. The machine must align with how coils are managed in your facility. For instance, lighter products may require manual loading, while conveyor systems are ideal for production line integration. Heavy coils often demand crane-loading capabilities, and forklifts provide flexibility for mid-weight handling. Choosing the right configuration enhances workflow, reduces downtime, and prevents mishandling. By matching the machine to your specific handling method, you ensure maximum compatibility and operational performance, tailored to your coil weight and size.

》By Manually

》By Crane

》By Conveyor

》By Forklifter

Selecting the right coil wrapping machine depends on the specific packaging requirements and coil handling methods. There are three key design types to consider:

Vertical Coil Wrapping Machine: Ideal for coils standing upright with their ID facing the wall. This economical solution is suitable for manual loading using forklifts, cranes, or rolling methods. It's particularly efficient for standard packaging needs with minimal automation.

Horizontal Coil Wrapping Machine: Designed for coils lying flat with their ID facing upward, this type is perfect for automated systems or specialized coils like copper or hose. Horizontal wrapping ensures secure packaging for irregularly shaped, lightweight, or small-ID coils, offering flexibility and precision.

Automatic Coil Wrapping Machine: Fully automated solutions cater to high-volume production lines, ensuring consistent and efficient packaging. These systems integrate seamlessly with conveyors and other automated equipment.

By understanding your coil type, handling method, and desired automation level, you can select a wrapping machine that enhances efficiency and meets your specific operational needs.

Selecting the appropriate packing material for coil packaging is essential to ensure product safety and cost-effectiveness. The choice depends on the coil type, transportation needs, and environmental factors. Here are the key options:

Stretch Film: Made of LLDPE, this is a cost-effective material offering sealed packaging with excellent tension control and overlap. It’s ideal for water and moisture resistance, making it a top choice for general-purpose packaging.

Reinforced Paper: While standard paper lacks strength, reinforced paper with PP belts and PE film provides durable, wear-resistant packaging. It’s suitable for steel, copper, and wire coils, offering moisture protection with VCI formulas for sea-worthy or rainy-season packaging.

HDPE/PE Film: A non-glue film over 50 microns thick, it protects coils from scratches and is ideal for ensuring surface integrity during transport.

Woven Knit Belt: Made of PP, this flexible yet strong material is perfect for rough handling, such as razor wire and heavy steel coils, providing enhanced protection against abrasions.

Our team will reply in 24 hours

![]() Email: info@fhopepack.com

Email: info@fhopepack.com

![]() Whatsapp: 0086-13951501635

Whatsapp: 0086-13951501635

I'm online now.