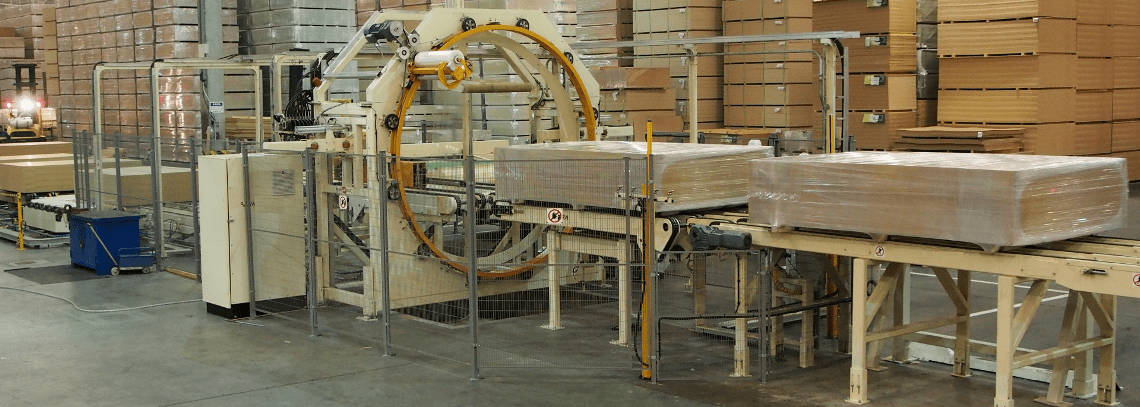

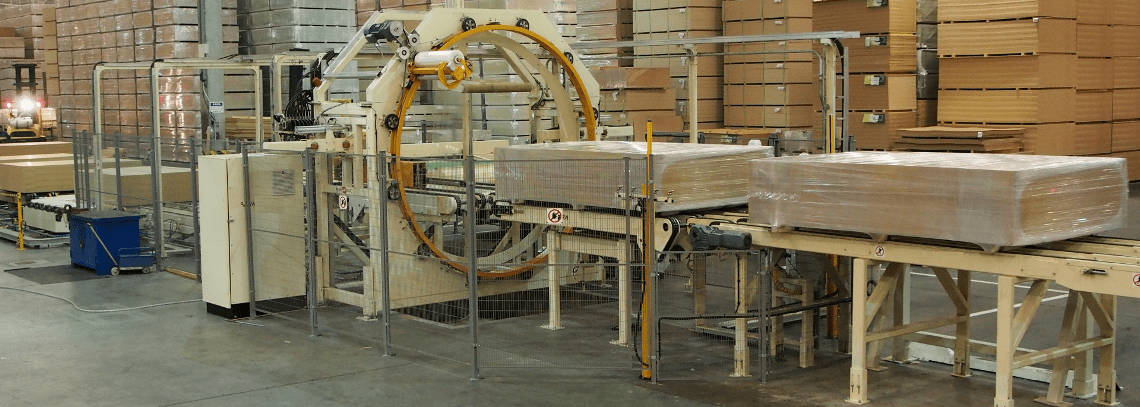

Panel Orbital Wrapping Machine: Your Ultimate Packaging Solution

The Panel Orbital Wrapping Machine provides an advanced packaging solution designed specifically for flat and elongated items such as panels, boards, and other large sheet materials. By leveraging state-of-the-art orbital technology, this machine ensures seamless wrapping with a continuous band of stretch film, offering comprehensive protection during transit and storage. Here’s everything you need to know about this efficient, durable, and versatile machine.

Features and Benefits

1. Superior Protection

-

Dust and Moisture Shield: The tight wrapping safeguards products from environmental factors like dust and moisture.

-

Surface Damage Prevention: Ensures no scratches or abrasions occur during handling and transit.

2. Versatile Applications

-

Suitable for wrapping a wide variety of products, including flat panels, boards, doors, and more.

3. Advanced Customization

-

Adjustable Speed: Tailor the wrapping speed based on product dimensions and materials.

-

Film Tension Control: Fine-tune the film tension to achieve optimal security without damaging the product.

4. Enhanced Operational Efficiency

-

Semi-Automatic and Fully-Automatic Modes: Offers operational flexibility to suit diverse industrial requirements.

-

Reliable Performance: Built for durability, ensuring long-term reliability in demanding environments.

Technical Specifications

|

Category

|

Details

|

|

Machine Type

|

Orbital Stretch Wrapper

|

|

Product Compatibility

|

Flat panels, boards, doors, and large sheets

|

|

Operation Modes

|

Semi-Automatic and Fully-Automatic

|

|

Wrapping Material

|

Stretch film, polyethylene film, woven tape

|

|

Power Requirement

|

240V/380V, 50/60Hz

|

Industrial Applications

1. Handlebar Assembly Protection

-

Application: Safeguards handlebars from scratches during transport.

-

Product Dimensions: 800mm (length), 100mm (width), 3kg (weight).

-

Wrapping Materials:

-

Stretch Film: OD: 150mm, ID: 76mm, Width: 200mm.

-

Foam Film: Adds 300mm width for extra cushioning.

-

Benefits: Protects against impacts and ensures handlebars remain in pristine condition upon delivery.

2. Accessory Kit Packaging

-

Application: Efficiently wraps smaller motorcycle accessories like mirrors, brake handles, and gear levers.

-

Product Dimensions: Typically ≤0.3 meters in any dimension, weighing ~5kg.

-

Wrapping Materials:

-

Stretch Film: OD: 100mm, ID: 76mm, Width: 100mm.

-

Bubble Film: Width: 500mm for added cushioning.

-

Benefits: Minimizes transit damage, ensuring accessories are securely fastened and ready for immediate use.

3. Complete Motorcycle Packaging

-

Application: Wraps and protects whole motorcycles for transit.

-

Product Dimensions:

-

Length: 2.1 meters.

-

Width: 0.8 meters.

-

Weight: ~150kg.

-

Wrapping Materials:

-

Stretch Film: OD: 200mm, ID: 76mm, Width: 500mm.

-

Woven Sheet: Width: 1200mm for superior protection.

-

Benefits: Prevents scratches and environmental damages, maintaining motorcycles in showroom-ready condition.

Why Choose the Panel Orbital Wrapping Machine?

1. Cost-Effectiveness

-

Reduces packaging waste while offering excellent product protection.

2. Productivity Boost

-

Speeds up the wrapping process, reducing manual labor and operational downtime.

3. Reliability and Durability

-

Designed to withstand industrial use, ensuring consistent performance for years.

4. Customization Flexibility

-

Adapts seamlessly to various industries and product requirements.

Conclusion

The Panel Orbital Wrapping Machine revolutionizes the packaging process with its blend of technology, efficiency, and versatility. Whether you’re protecting small accessories or wrapping entire motorcycles, this machine guarantees top-notch results, enhancing your operations and ensuring customer satisfaction. Upgrade your packaging workflow today with this indispensable tool.

Frequently Asked Questions (FAQs)

1. What materials can be used with the Panel Orbital Wrapping Machine?

The machine is compatible with stretch film, polyethylene film, and woven tape, making it adaptable to different packaging needs.

2. Is the machine suitable for fragile items?

Yes, its adjustable tension control and optional bubble or foam film layers make it ideal for wrapping delicate products securely.

3. Can this machine handle irregularly shaped items?

Yes, the orbital wrapping technology allows for effective wrapping of irregularly shaped items, ensuring complete coverage.

4. What industries benefit most from this machine?

Industries like manufacturing, logistics, furniture, and automotive benefit significantly from the Panel Orbital Wrapping Machine.

5. Is the machine easy to operate?

Absolutely! With both semi-automatic and fully-automatic modes, the machine is user-friendly and requires minimal training.

Panel Orbital Wrapping Machine

The packaging process is the unsung hero of product delivery. Think about it: no matter how innovative or pristine your product is, if it doesn’t arrive intact, all that effort goes down the drain. That’s where the Panel Orbital Wrapping Machine steps in. This isn’t just another industrial tool; it’s a revolutionary solution for protecting large, flat items during transport and storage.

Imagine sending a custom-made wooden door or a delicate glass panel across miles. You can’t afford scratches, moisture damage, or debris ruining your hard work. This machine takes that stress off your shoulders, wrapping each product securely, like a protective cocoon.

Whether you're managing high-volume production lines or dealing with smaller batches, this machine tailors its performance to your specific needs. It's efficiency, precision, and protection all rolled into one sleek, robust design.

1. How Does the Panel Orbital Wrapping Machine Work?

1.1 Understanding Orbital Wrapping Technology

At the heart of the Panel Orbital Wrapping Machine lies an innovative orbital wrapping mechanism. Unlike conventional packaging tools, this machine wraps products with a continuous band of stretch film while rotating around them. Think of it like a planet orbiting the sun—every revolution tightens the wrap, providing consistent coverage.

The beauty of this design is its adaptability. Whether you’re wrapping a flat metal sheet or a stack of large boards, the orbital process ensures every inch is securely enveloped. By maintaining even pressure and tension, it prevents loose ends or weak spots in the packaging.

This technology also eliminates the need for bulky boxes or excessive padding. Instead, it delivers sleek, space-saving packaging that’s lighter to transport and easier to handle.

1.2 Why Stretch Film is Ideal for Wrapping

Stretch film isn’t just any plastic—it’s a marvel of engineering. Its elasticity, strength, and transparency make it a superstar in the packaging world. When applied with the orbital wrapping machine, stretch film provides:

-

Tight Coverage: It clings to the product like a second skin.

-

Moisture Resistance: Keeps water, humidity, and dirt at bay.

-

Durability: Resistant to tears and punctures, even during rough handling.

The film's transparency is another game-changer. Need to identify a panel without unwrapping it? No problem—just peek through the film. Additionally, the material is cost-effective and eco-friendly when used efficiently.

1.3 Adapting to Various Product Sizes and Shapes

One of the standout features of the Panel Orbital Wrapping Machine is its ability to handle diverse shapes and sizes. With customizable settings, it adjusts seamlessly to wrap items as small as compact boards or as large as full-size panels.

How does it achieve this?

-

Adjustable Tension Control: Tailors the film’s tightness to match the product's fragility.

-

Flexible Rotation Speeds: Allows for faster wrapping of smaller items or careful, slower coverage for delicate materials.

-

Universal Compatibility: Accepts various wrapping films, from polyethylene to woven tape, ensuring optimal protection for every use case.

This adaptability translates to increased versatility on the production floor, saving time and reducing the need for multiple machines.

2. What Are the Benefits of Using an Orbital Wrapping Machine?

2.1 Enhanced Protection for Products

The primary goal of any packaging solution is to protect the product—and this machine excels at it. The continuous stretch film wrap acts as an impenetrable barrier against external threats such as:

-

Dust and dirt accumulation.

-

Moisture damage, including corrosion or warping.

-

Scratches and surface abrasions.

Let’s not forget the added layer of safety during transport. Even in high-vibration conditions, the snug wrapping prevents products from shifting, reducing the risk of damage.

2.2 Efficiency Gains for Your Operations

Time is money, especially in high-output industries. The Panel Orbital Wrapping Machine speeds up the packaging process significantly compared to manual wrapping or older technologies. Here’s how:

-

Reduced Labor: With semi-automatic and fully-automatic modes, fewer hands are needed on deck.

-

Consistent Quality: Machines don’t get tired, which means every product is wrapped perfectly, every time.

-

Faster Turnaround: High-speed rotation and wrapping ensure your production line keeps moving smoothly.

These efficiency gains ripple through the rest of your operation, enhancing productivity and lowering costs.

2.3 Customization Features That Save Time and Money

Every industry has unique packaging needs, and the Panel Orbital Wrapping Machine caters to them all. Its customization options make it a one-size-fits-all solution:

-

Variable Wrapping Modes: Switch between light protective wraps and heavy-duty coverings.

-

Film Usage Optimization: Minimizes material waste by applying just the right amount of film.

-

Built-In Diagnostics: Many models feature self-check systems, alerting you to maintenance needs before problems arise.

These features not only improve operational efficiency but also reduce material costs and downtime, ensuring a higher return on investment.

3. Which Industries Rely on the Panel Orbital Wrapping Machine?

3.1 Applications in Manufacturing

Manufacturing is one of the primary industries benefiting from the Panel Orbital Wrapping Machine. Whether it’s large-scale furniture production or custom metalworking, protecting flat products is crucial. Delicate wooden boards, industrial glass panels, or even aluminum sheets require careful packaging to maintain their surface integrity.

By integrating orbital wrapping into their workflow, manufacturers achieve:

-

Seamless Product Protection: The stretch film shields products from dust, moisture, and accidental scratches.

-

Efficient Bulk Packaging: Large batches of items can be wrapped in a fraction of the time required by manual methods.

-

Reduced Material Waste: The machine optimizes film usage, saving money while minimizing environmental impact.

In manufacturing, precision and speed are paramount. This machine ensures both, enabling businesses to meet tight deadlines without compromising quality.

3.2 Use Cases in Logistics and Shipping

In logistics and shipping, the journey is often the most perilous part of a product’s lifecycle. Items face vibrations, collisions, and exposure to harsh environments. The Panel Orbital Wrapping Machine ensures products are packed securely, preventing:

-

Shifting during transit, which often leads to damage.

-

Contamination from dirt, oil, or water during handling.

Take, for example, logistics hubs dealing with large sheet metal shipments. Wrapping each panel tightly with durable stretch film minimizes risks and maximizes customer satisfaction upon delivery.

3.3 Adoption Across Niche Sectors

Beyond traditional manufacturing and logistics, niche industries are also leveraging the machine’s capabilities. For instance:

-

Automotive Sector: Wrapping delicate vehicle components such as door panels or dashboard materials.

-

Solar Panel Production: Protecting fragile solar cells and frames during storage and transport.

-

Architectural Glass Industry: Ensuring high-value glass panels are preserved without surface imperfections.

The Panel Orbital Wrapping Machine is becoming a universal solution, adaptable to countless scenarios across industries.

4. How to Choose the Right Panel Orbital Wrapping Machine for Your Needs?

4.1 Factors to Consider When Choosing

Selecting the right wrapping machine depends on your specific operational requirements. Here are key factors to weigh:

-

Product Dimensions: Does the machine accommodate the size and shape of your products?

-

Material Compatibility: Check if it supports stretch film, polyethylene, or woven tape based on your needs.

-

Automation Level: Decide between semi-automatic and fully-automatic models based on your production volume.

-

Speed and Efficiency: Ensure the machine matches your desired throughput without compromising wrap quality.

By analyzing these factors, you can pinpoint the model that aligns with your packaging goals.

4.2 Comparing Features Across Models

Not all orbital wrapping machines are created equal. When comparing models, focus on these distinguishing features:

-

Tension Control Options: Essential for fragile or delicate items.

-

Film Feed Mechanism: Look for machines with precise film-feeding systems to minimize waste.

-

Maintenance Requirements: Opt for models with self-diagnostic tools to reduce downtime.

Investing time in comparison ensures your choice delivers long-term value.

4.3 Making the Most of Your Investment

Once you’ve chosen the right machine, maximizing its potential is the next step:

-

Employee Training: Ensure operators are well-versed in using the machine for optimal performance.

-

Regular Maintenance: Schedule maintenance checks to keep the machine running smoothly.

-

Customization Trials: Experiment with settings to find the perfect combination for different product types.

A strategic approach to implementation ensures your investment pays off in terms of efficiency and reliability.

Conclusion

The Panel Orbital Wrapping Machine is more than just a tool—it’s a game-changer for industries requiring secure, efficient, and adaptable packaging solutions. From manufacturing plants to logistics hubs, this machine provides unmatched protection, saving time, reducing waste, and ensuring products reach their destination in pristine condition.

Whether you’re wrapping delicate accessories or large, flat panels, this machine is your partner in achieving operational excellence. Its flexibility, precision, and durability make it a must-have for businesses that prioritize quality and efficiency.

Claim

When it comes to packaging flat or elongated products, there’s no better choice than the Panel Orbital Wrapping Machine.