Click to Chat

I'm online now.

Fhopepack Innovation

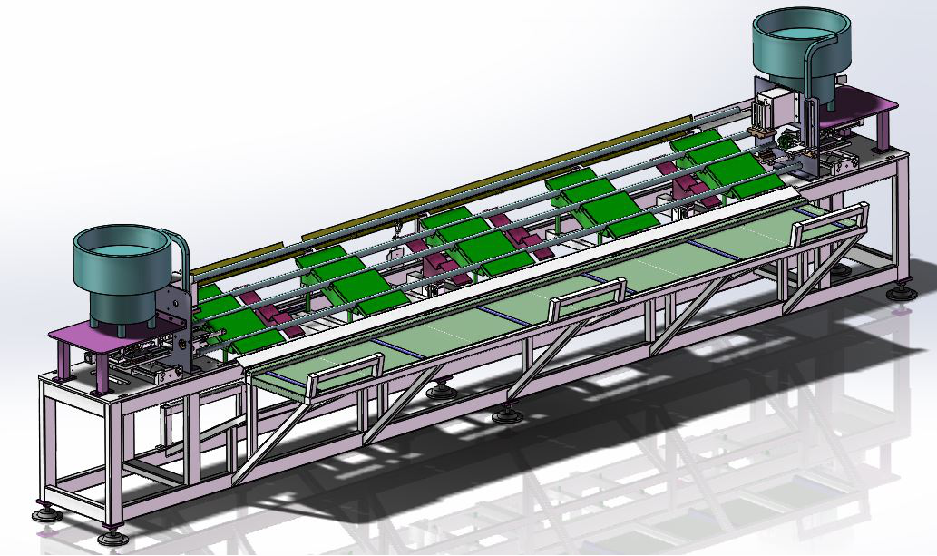

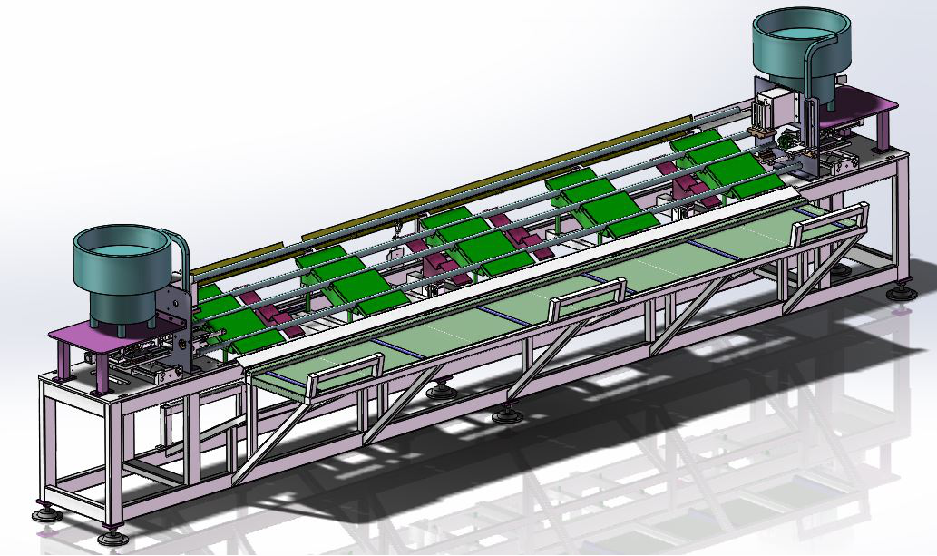

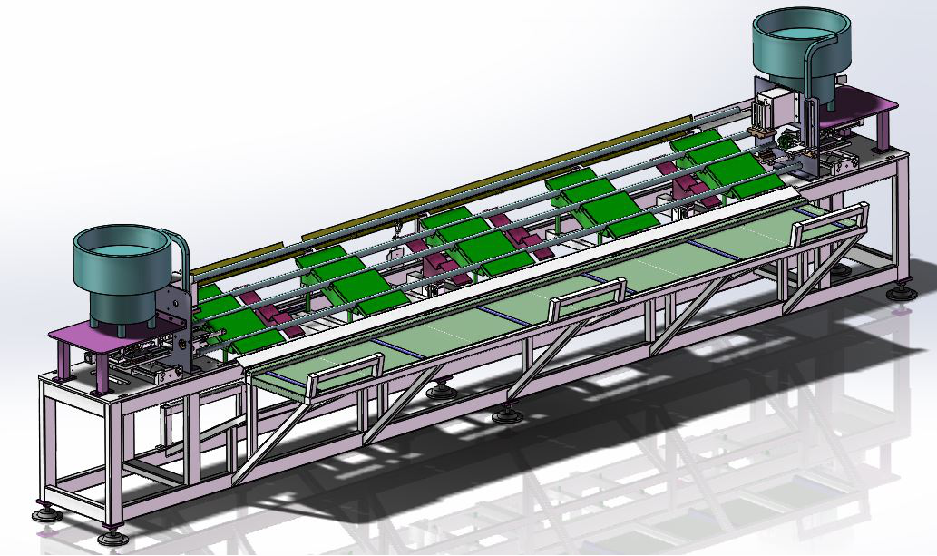

Design Drawing: Originality: Current industry status:The capping machine has high requirements on the geometric shape of the pipe cap, the cap can not have flash, and the failure rate of the cap is generally 1-5%. After many research and development tests, the industry's first opening and closing cap tooling was developed, which completely solved the failure of cap and the high requirements

Design Drawing:

Originality:

Current industry status:The capping machine has high requirements on the geometric shape of the pipe cap, the cap can not have flash, and the failure rate of the cap is generally 1-5%.

After many research and development tests, the industry's first opening and closing cap tooling was developed, which completely solved the failure of cap and the high requirements for cap.

QMGM capping machine has no special requirements for cap.

The failure rate is less than 0.002%.

This innovation is applying for a national patent.

In recent years, the labor cost has been rising continuously, and enterprises urgently need to upgrade the automation level to cope with the increasing cost pressure. Therefore, Shanghai Fhope Machinery Co., Ltd. has developed a full-automatic pipe capping machine after a year's efforts.

The machine has perfect self-checking function, highly reliable process and extremely low failure rate of cap.

The production process needs no human monitoring and is highly automated.

Compatible with multiple specifications (20,25,32), easy to change specifications.

Compatible with two length specifications (3m, 4m)

There is no requirement for the pipe cap.

Operational Environment:

Environment: indoor, no dust.

Mode: On-line, directly placed in the original turning rack.

Power supply: AC220V 50Hz.

Power: less than 1.5KW.

Compressed air: more than 0.5MPa

Gas consumption: 200cm³/ time.

Center height: standard 1m, customized with other specifications.

Working specifications mm: 20,25,32.

Tube cap requirements: injection molded tube cap, allowing elastic deformation, no adhesion.

Fitting of pipe cap: the inner diameter of cap shall not be smaller than the outer diameter of pipe.

Tube length: 3m, 4m+/-4mm, and the time for changing the length specification is less than 10min.

Vibrating disc: Three specifications are compatible, and the time for changing the pipe diameter specification is less than 10 minutes.

Failure rate of cap: the typical value is less than 1/50,000 (the equipment is electrically normal and the machinery is free from abnormal wear).

Functional Mode:

Cap pressure is adjusted separately.

The minimum cycle time of cap is 1.5 seconds (the maximum frequency is 40 times/min, and the maximum production speed can reach 160 meters/min if the pipe length is 4 meters).

The action of cap has double interlocking of time and switch signal.

Cap count.

Failure count (optional)

Cycle timing

Calculation of production speed.

Class yield calculation.

Packaging counting is convenient for manual packaging.

Manual function

Protection time setting.

fault-tolerant capability

Pipe diameter detection (optional, imported from Japan, with accuracy of 1 micron).

Labeling (optional, disc label)

Abnormal interlocking (if the customer provides size or other abnormal signals, identify whether the cap is blocked, and do not turn the cap over to the abnormal side).

Alarm Prompt:

Tube cap bin detection alarm.

Check the position of the cap pipe, and give an alarm if a switch is damaged or the pipe position is incorrect.

Button connection error or disconnection alarm.

Cap failure detection alarm (optional).

Pipe cap tooling inspection to identify whether to send the cap (optional).

Abnormal cylinder action alarm.

I'm online now.