Click to Chat

I'm online now.

Fhopepack Innovation

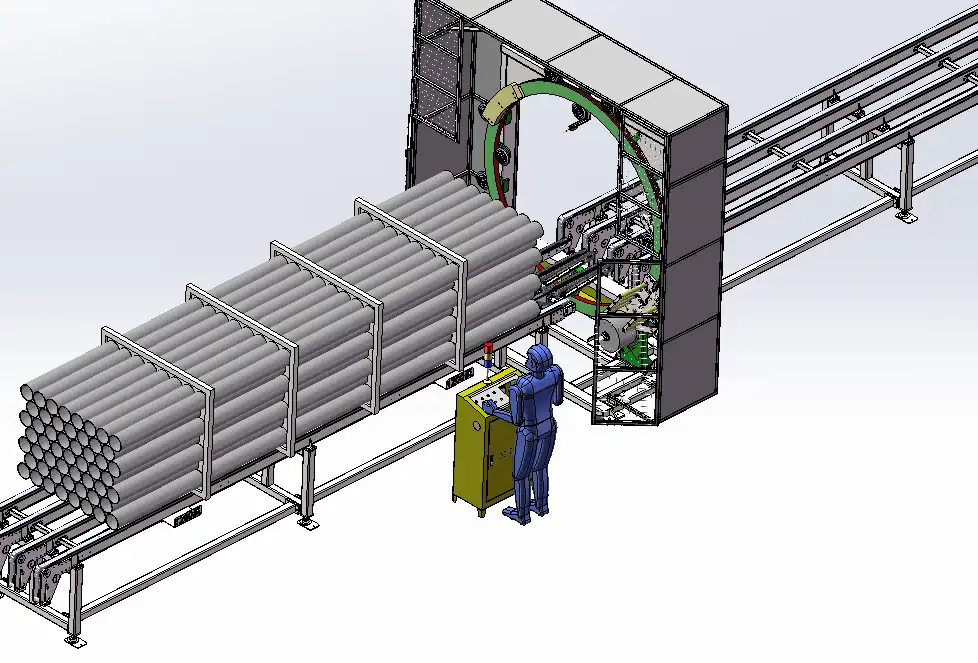

Pallet Orbital Wrapping Machines provide robust and efficient solutions for securing palletized goods. These machines wrap pallets horizontally, ensuring stability and protection against dust, moisture, and damage during storage and transit. Ideal for various industries, they enhance productivity and safeguard products effectively.

Pallet Orbital Wrapping Machines are indispensable tools for industries that demand secure, efficient, and cost-effective packaging solutions for palletized goods. These machines streamline the wrapping process by horizontally enveloping goods with stretch film, offering superior protection against external elements like moisture, dust, and physical damage.

This guide provides a detailed look into the features, specifications, and industry applications of these machines, emphasizing their role in enhancing operational efficiency and maintaining product integrity.

Efficient Horizontal Wrapping

Customizable Speed and Settings

Material Compatibility

Enhanced Protection

Labor and Material Savings

| Feature | Details |

|---|---|

| Machine Type | Orbital |

| Pallet Size Compatibility | Length: Up to 2400 mm, Width: Up to 1200 mm |

| Wrapping Material Type | Stretch Film |

| Film Specifications | Width: Up to 500 mm, Thickness: 17-35 microns |

| Wrap Speed |

Adjustable, up to 12 RPM |

Cost Efficiency

Operational Versatility

Environmental Sustainability

Enhanced Product Integrity

Pallet Orbital Wrapping Machines offer a robust, reliable, and scalable solution for businesses aiming to enhance the safety and security of their products during storage and transport. By automating the packaging process, these machines not only improve efficiency but also ensure consistent results, making them an invaluable asset in today’s demanding markets.

What industries benefit most from Pallet Orbital Wrapping Machines?

Can these machines handle irregularly shaped items?

What are the maintenance requirements?

How does using these machines reduce costs?

Are the machines compatible with eco-friendly materials?

The modern logistics landscape demands efficiency, speed, and precision, especially when handling palletized goods. Enter the pallet orbital wrapping machine: a game-changer for industries striving to meet these demands. This innovative technology simplifies securing loads, ensures product safety, and minimizes material waste—all while saving time and money.

Pallet orbital wrapping machines have revolutionized how businesses package and transport goods. But what makes them indispensable in today's fast-paced supply chain? Their ability to accommodate varying load sizes, improve wrapping consistency, and integrate seamlessly into automated systems makes them essential for operations of all scales.

For businesses looking to enhance efficiency without compromising on load security, understanding the advantages of pallet orbital wrapping machines is vital. Let’s explore how they work, their benefits, and what to consider when choosing one.

Pallet orbital wrapping machines employ a rotating ring to wrap film around a load. Unlike traditional stretch wrappers, these machines rotate the packaging material rather than the pallet, enabling precise and uniform wrapping even for irregularly shaped items.

The design ensures optimal film tension and placement, which enhances load stability during transit. With customizable settings, businesses can adjust film overlap and wrapping speed based on the requirements of specific shipments, ensuring a perfect balance between security and material usage.

Material waste is a common challenge in packaging operations, but orbital wrapping machines address this issue effectively. By leveraging pre-stretch film technology, they maximize the use of each roll, reducing the overall material cost and environmental footprint.

Moreover, advanced models include sensors that adjust the film application based on load dimensions, ensuring no unnecessary layers are applied. This level of precision not only cuts costs but also supports sustainability initiatives, a growing priority for many organizations.

One of the standout advantages of pallet orbital wrapping machines is their ability to streamline workflows. Traditional wrapping methods often involve manual labor, which can lead to inconsistencies and slower turnaround times.

With automated systems, wrapping speeds increase significantly, allowing businesses to process more pallets in less time. Furthermore, the consistency achieved with these machines reduces the risk of improperly secured loads, preventing damage and enhancing customer satisfaction.

Every operation has unique needs, from load sizes to throughput requirements. When selecting a pallet orbital wrapping machine, it's crucial to ensure compatibility with existing workflows and infrastructure.

Consider factors such as the types of pallets handled, the size of the available floor space, and the integration potential with other systems like conveyors or automated guided vehicles (AGVs). Choosing a machine that aligns seamlessly with your operations can prevent costly downtime and maximize ROI.

While automation can significantly enhance efficiency, it’s essential to weigh the upfront investment against long-term savings. Factors like reduced labor costs, faster cycle times, and minimized material waste contribute to a compelling value proposition for orbital wrapping machines.

Additionally, automation reduces reliance on manual intervention, lowering the risk of workplace injuries and ensuring compliance with safety standards. For businesses scaling operations, these benefits often outweigh the initial expenditure.

Modern pallet orbital wrapping machines come equipped with a range of features designed to improve adaptability. Look for machines with adjustable tension controls, variable wrapping modes, and easy-to-use interfaces.

The ability to customize settings allows businesses to handle diverse load types, from fragile goods to heavy-duty industrial equipment. Machines that offer quick-change film systems and remote monitoring capabilities further enhance operational flexibility, making them a versatile choice for dynamic supply chains.

Pallet orbital wrapping machines are at the forefront of sustainable packaging solutions. By utilizing pre-stretch technology, these machines minimize plastic usage per load without compromising on load security. Businesses can achieve optimal wrapping with less material, significantly reducing their plastic waste.

Furthermore, many modern machines are compatible with biodegradable and recyclable films, aligning with eco-conscious practices. Companies adopting these solutions can enhance their environmental credentials and appeal to sustainability-focused customers.

Energy efficiency is another critical aspect of sustainability. Advanced pallet orbital wrapping machines are designed to consume less power, thanks to optimized motors and automated control systems.

Incorporating such machines into operations reduces utility costs and aligns with global initiatives to minimize carbon footprints. For large-scale facilities, the cumulative energy savings over time can be substantial, contributing to both environmental and economic benefits.

Sustainability doesn’t stop at material reduction—it extends to fostering a circular economy. Businesses can implement pallet orbital wrapping systems to complement recycling programs by reclaiming and reusing packaging films.

These machines' precise application reduces film damage, allowing for more effective recycling. The integration of such systems into packaging workflows demonstrates a commitment to sustainable practices, setting a benchmark for the industry.

One of the most significant advantages of pallet orbital wrapping machines is the reduction of manual labor. Traditional wrapping methods often involve repetitive movements, increasing the risk of strain injuries among workers.

By automating the wrapping process, these machines eliminate the need for employees to manually handle heavy loads or stretch film, creating a safer and more ergonomic work environment.

Proper load stabilization is crucial for preventing accidents during handling, transit, and storage. Pallet orbital wrapping machines ensure that loads are consistently wrapped to withstand external forces, reducing the likelihood of shifting or collapsing pallets.

This stability not only protects products but also safeguards employees from potential hazards associated with unstable loads. With features like tension control and customizable wrap patterns, these machines provide enhanced safety at every stage of the supply chain.

Compliance with workplace safety regulations is a top priority for any business. Pallet orbital wrapping machines often come equipped with advanced safety features such as emergency stop buttons, sensors to detect obstructions, and protective barriers around moving parts.

By incorporating these machines, companies can ensure adherence to safety standards, avoiding potential fines and fostering a culture of safety. In industries where regulations are strict, these features become an invaluable asset.

Pallet orbital wrapping machines are more than just tools—they are transformative assets for businesses aiming to optimize packaging efficiency, enhance workplace safety, and achieve sustainability goals. By automating and refining the wrapping process, these machines deliver tangible benefits across the supply chain, from reducing costs to improving load security.

For organizations ready to innovate and future-proof their operations, investing in a pallet orbital wrapping machine isn’t just a choice—it’s a strategic move toward long-term success.

[Claim]: Pallet orbital wrapping machines redefine efficiency and sustainability, setting new standards for packaging solutions.

I'm online now.