Click to Chat

I'm online now.

Fhopepack Innovation

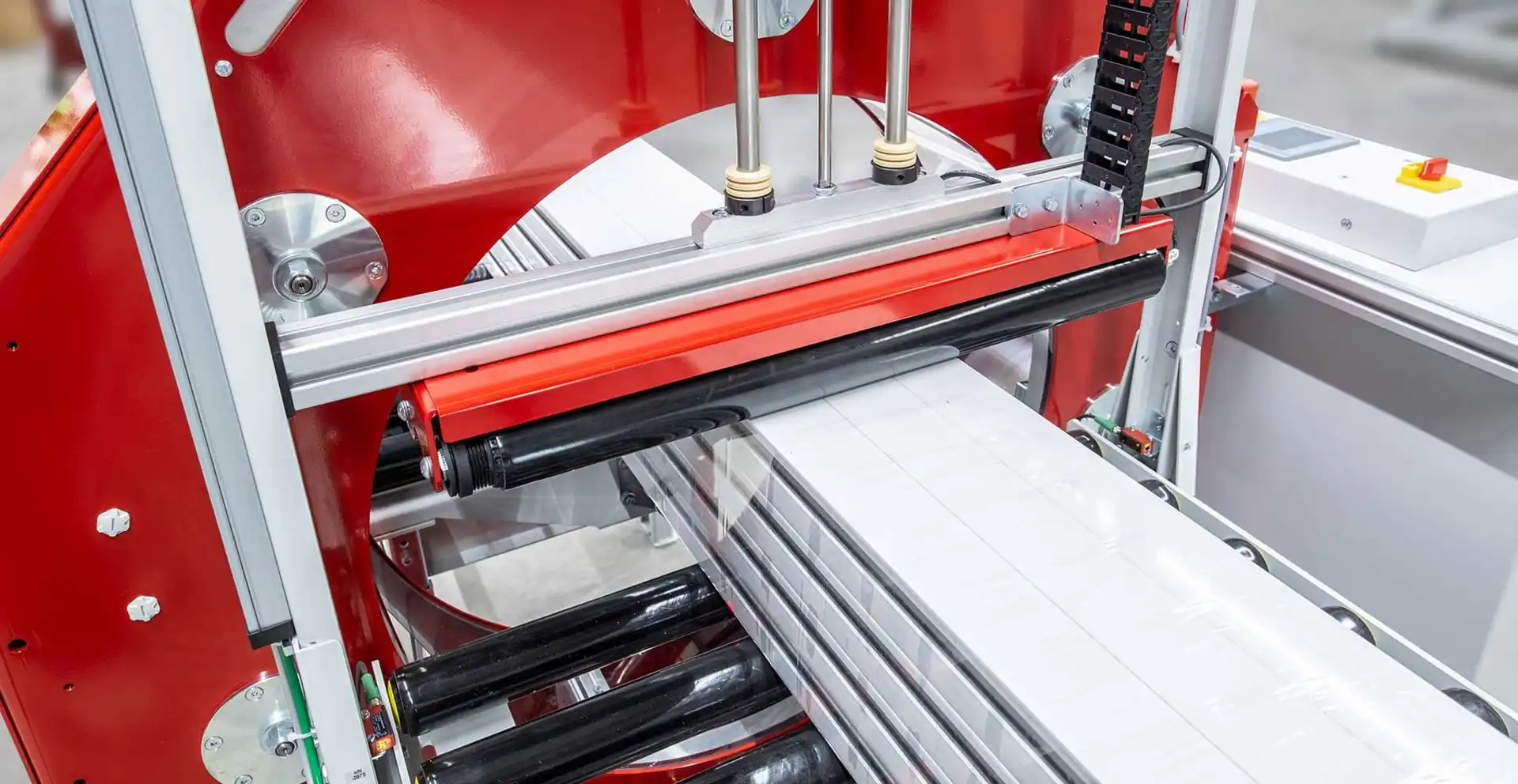

The Box Horizontal Wrapper is a cutting-edge machine tailored for efficient and secure packaging of boxes. It streamlines operations, minimizes material usage, and delivers uniform wrapping results. Perfect for high-volume industries, it combines reliability, speed, and versatility to meet diverse packaging requirements seamlessly.

The Automatic Horizontal Orbital Stretch Wrapper Machine by Fhope is engineered to deliver unparalleled performance for wrapping horizontal-shaped products. From pipes and sheets to doors, aluminum profiles, and building products, this machine ensures that every package is well-protected, sealed, and neatly arranged. Its ability to integrate seamlessly into a packing line enhances productivity and reduces labor dependence, making it a vital solution for modern industrial packaging.

Specialized Wrapping for Horizontal Shapes:

Seamless Automation:

Cost-Effective Packaging Solutions:

Stable and Efficient Operation:

Advanced Wrapping Capabilities:

Safety-First Design:

Product Protection:

Fully Automated Operation:

Customizable Speed and Adjustments:

Advanced Automation:

Error Detection and Alerts:

User-Friendly Interface:

Unmanned Operation:

Efficient Material Handling:

The Fhope orbital wrapper is versatile and designed for a wide range of industries, including:

Cost-Effective Systems:

Versatile Product Handling:

Reliable and Durable:

Fhope provides complete orbital wrapping solutions, including stretch films and advanced wrapping equipment, delivering the most cost-effective and efficient packaging systems for your needs.

| Technical Parameter | Details |

|---|---|

| Bundle OD | 100-300mm |

| Bundle Length | >1000mm |

| Weight | 15-100kg |

| In-Feeding Conveyor Length | 2000mm with motor |

| Out-Feeding Conveyor Length | 2000mm with motor |

| Speed | 6~12m/min |

| Ring Speed | 20-90r/min |

| Wrapping Speed | 5-15m/min |

| Power Output | About 2.5kw |

| Power Voltage | 380v, 3PH, 60Hz |

| Packing Material | Polyethylene Foil |

| OD | 100-200mm |

| Width | 100-200mm |

| ID | 50mm |

I'm online now.