Click to Chat

I'm online now.

Fhopepack Innovation

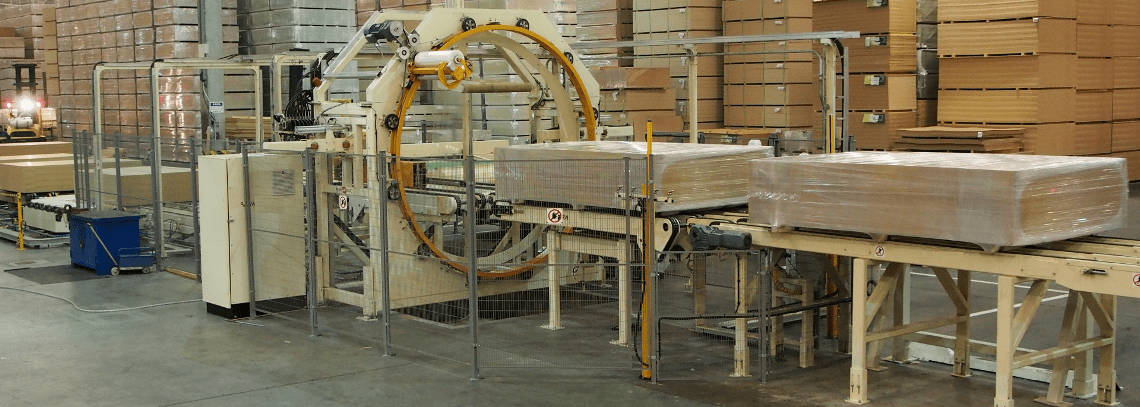

The Spiral Orbital Wrapping Machine is engineered for high-efficiency wrapping of elongated products such as lumber, pipes, and profiles. Utilizing a spiral motion, it securely wraps items in continuous film, ensuring thorough protection and stabilization for transportation and storage. This machine is robust, fast, and adaptable to various product dimensions.

The Spiral Orbital Wrapping Machine is specifically designed for efficient and secure packaging of elongated items such as metal rods, wooden planks, and plastic tubing. This machine utilizes a unique orbital motion to wrap products in a tight spiral of protective film, providing superior protection against moisture, dirt, and physical damage during transit or storage.

Key Features:

This machine is an invaluable asset for manufacturers and distributors aiming to elevate their packaging processes while safeguarding product quality.

| Feature | Details |

|---|---|

| Machine Type | Orbital |

| Maximum Wrap Size | Length: Unlimited; Diameter: Up to 400 mm |

| Wrap Speed | Up to 100 meters per minute |

| Film Width | 250 mm to 500 mm |

| Power Supply | 220V/380V, 50/60 Hz |

Efficient and durable packaging solutions are at the heart of every thriving manufacturing process. A spiral orbital wrapping machine embodies this ethos, offering an automated, secure way to protect products during transit and storage.

These machines aren’t just about wrapping; they’re about enhancing efficiency, reducing costs, and providing reliability for businesses looking to scale their operations. With innovation as the driving force, understanding their capabilities and advantages is paramount for decision-makers.

From heavy-duty industrial applications to niche packaging requirements, spiral orbital wrapping machines redefine operational standards. Let’s delve into the essential factors and unique attributes that make these machines a staple in advanced production lines.

Efficiency is a cornerstone of modern production, and spiral orbital wrapping machines deliver on this promise by streamlining packaging tasks. Unlike manual or semi-automatic solutions, these machines can handle high volumes with minimal downtime. By automating the wrapping process, they not only reduce labor dependency but also ensure consistent, uniform packaging that enhances product presentation and protection.

A well-designed spiral orbital wrapper integrates seamlessly into assembly lines, adapting to varying product dimensions and shapes. This versatility makes it an ideal solution for industries dealing with irregularly shaped or delicate goods.

What sets these machines apart is their design—a harmony of form and function. They feature an orbital ring system that rotates the wrapping material around the product, creating a snug, protective layer without compromising the item’s structural integrity. This innovative mechanism minimizes material usage while maximizing coverage, which is a win-win for both operational costs and environmental impact.

The ability to customize settings for tension, speed, and material type further underscores the adaptability of these machines. Whether it’s lightweight plastic or heavy-duty stretch film, the machine handles it effortlessly, catering to diverse industrial needs.

In industrial environments, durability isn’t just an advantage—it’s a necessity. Spiral orbital wrapping machines are built with robust components designed to withstand continuous operation in demanding conditions. High-grade materials, precision engineering, and minimal wear-and-tear mechanisms contribute to their long operational life.

For businesses investing in long-term packaging solutions, this durability translates into lower maintenance costs and reduced equipment downtime. Over time, the return on investment becomes apparent, as the machine’s consistent performance boosts overall productivity.

The beauty of automation lies in its ability to handle repetitive tasks with pinpoint accuracy. Spiral orbital wrapping machines exemplify this by delivering precision in every wrap, ensuring products are securely packaged for transport or storage. Advanced sensors and programmable logic controllers (PLCs) enable real-time adjustments, accommodating variations in product size or material properties without manual intervention.

Automation also eliminates the risk of human error, which is a common issue in manual wrapping processes. This reduction in errors improves not only product safety but also customer satisfaction, as fewer goods are damaged or improperly packaged.

One of the most compelling benefits of adopting spiral orbital wrapping machines is the cost savings they bring. By optimizing material usage, these machines significantly reduce wastage compared to traditional wrapping methods. Stretch film and other materials are applied precisely where needed, minimizing excess consumption and contributing to sustainability goals.

Moreover, the reduction in labor costs cannot be overlooked. These machines allow operators to focus on higher-value tasks, streamlining workforce allocation and improving overall efficiency. Over time, the combined savings on materials, labor, and maintenance make a strong financial case for adopting this technology.

Businesses across various sectors have reaped transformative benefits from integrating spiral orbital wrapping machines into their workflows. For instance, a steel manufacturer saw a 30% reduction in packaging costs after transitioning from manual wrapping to automated orbital systems. This not only improved their profit margins but also enhanced their ability to meet tight deadlines without compromising quality.

The adaptability of these machines also extends to smaller-scale operations. A local furniture manufacturer reported a significant drop in customer complaints related to damaged goods, thanks to the reliable packaging provided by their new orbital wrapping system.

The heavy manufacturing sector relies on robust packaging solutions to protect products like steel coils, pipes, and other industrial components during transit. Spiral orbital wrapping machines are tailor-made for these scenarios, providing the durability and adaptability needed to handle large, heavy items. Their ability to securely wrap irregular shapes and dimensions minimizes the risk of damage, ensuring that goods arrive at their destination in perfect condition.

The reliability of these machines makes them indispensable in high-stakes environments where damaged shipments can result in substantial financial losses or customer dissatisfaction.

Logistics and warehousing companies face unique challenges in managing diverse inventory, often requiring rapid packaging solutions. Spiral orbital wrapping machines excel in this context, offering speed and versatility to handle varying product sizes and quantities. By automating the wrapping process, these businesses can enhance throughput, reduce delays, and maintain a consistent packaging standard.

In a competitive industry where time is money, the efficiency brought by these machines allows businesses to process orders faster, improving their overall supply chain performance and customer satisfaction.

The rise of e-commerce has placed an emphasis on secure, visually appealing packaging. Spiral orbital wrapping machines meet these demands by providing a professional finish while protecting goods during transit. For retailers, this ensures that their products arrive intact and maintain their presentation, which is crucial for customer retention and brand loyalty.

Smaller e-commerce businesses can also benefit by using compact models of these machines, making advanced packaging technology accessible even to operations with limited space and budget. This scalability underscores their broad applicability across industries.

Sustainability is a pressing concern across industries, and spiral orbital wrapping machines contribute by optimizing material usage. These machines apply only the necessary amount of wrapping material, reducing waste significantly compared to manual methods. Advanced tension controls ensure that the film is stretched to its maximum potential, providing effective coverage with minimal resource consumption.

The reduction in waste not only lowers operational costs but also aligns businesses with environmental standards, improving their corporate social responsibility (CSR) profiles.

Modern spiral orbital wrapping machines are designed with energy efficiency in mind. Innovations such as low-energy motors and intelligent standby modes ensure that power consumption is minimized without compromising performance. For large-scale operations, this translates into substantial savings on energy bills and a smaller carbon footprint.

Moreover, businesses adopting energy-efficient equipment are better positioned to comply with sustainability regulations, enhancing their market reputation and competitive edge.

By reducing waste and improving resource efficiency, spiral orbital wrapping machines play a vital role in supporting circular economy goals. They enable businesses to reuse materials more effectively and streamline recycling processes. For example, some advanced models are compatible with biodegradable or recyclable wrapping films, further enhancing their eco-friendly credentials.

Companies adopting these technologies not only reduce their environmental impact but also demonstrate a commitment to innovation and sustainability, which resonates strongly with modern consumers.

The spiral orbital wrapping machine is more than just a tool; it’s a game-changer for industries seeking efficiency, durability, and sustainability in their packaging operations. By automating complex tasks and reducing material usage, these machines empower businesses to achieve operational excellence while minimizing costs and environmental impact.

[Claim]

Investing in a spiral orbital wrapping machine isn’t just about keeping up with industry standards; it’s about staying ahead. For businesses aiming to scale sustainably and efficiently, this technology offers an unparalleled opportunity to revolutionize their operations.

I'm online now.