Click to Chat

I'm online now.

Fhopepack Innovation

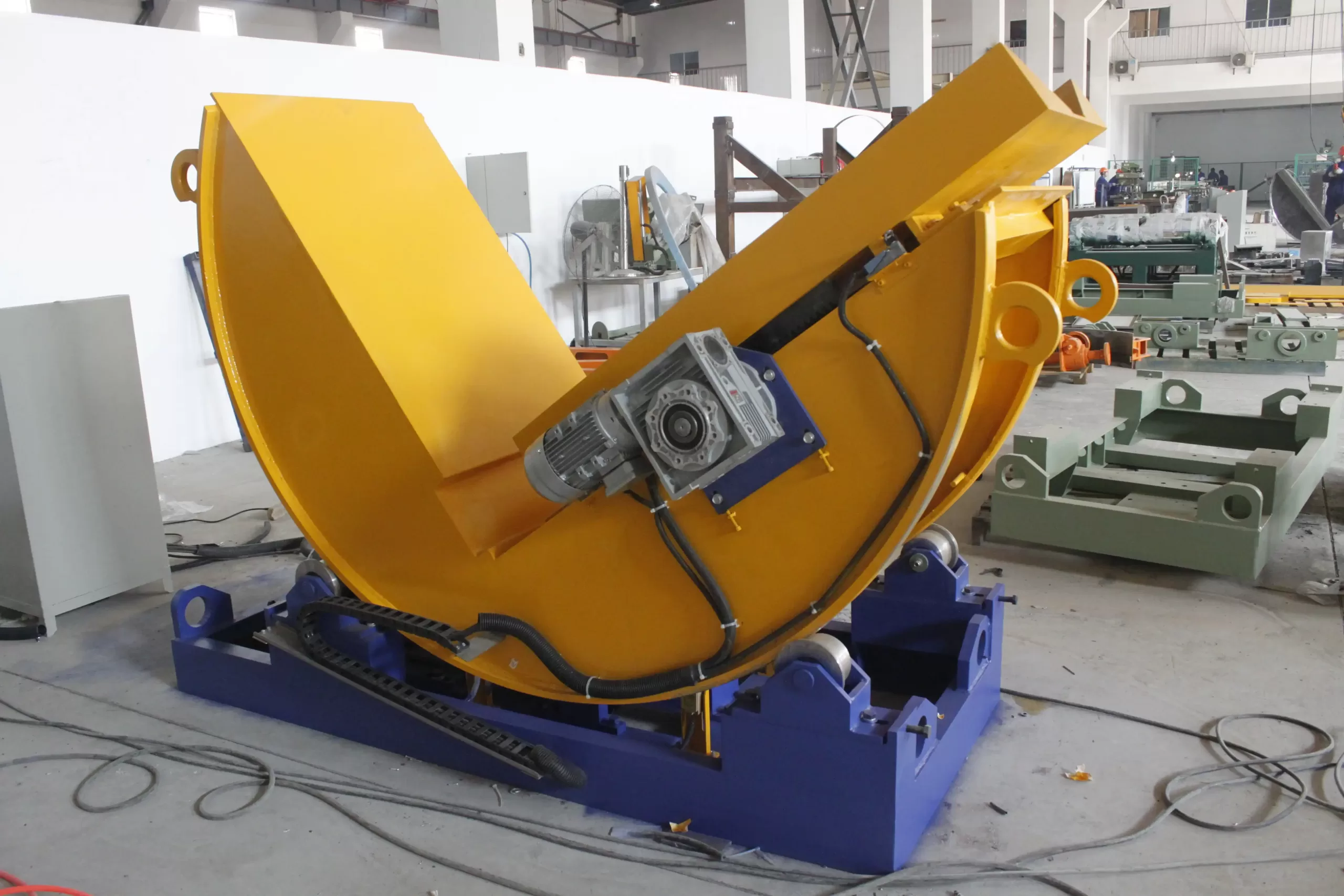

Stationary Upenders are engineered for safe and efficient repositioning of heavy and bulky loads. Ideal for industries requiring the rotation of coils, dies, and other materials, these upenders provide a 90-degree tilt, enhancing workflow and reducing labor strain. Built with robust materials, they ensure durability and reliability in demanding environments.

This article delves into the myriad ways coil upenders contribute to operational cost savings. We will explore how these machines streamline labor requirements, reducing the number of personnel needed for coil handling, which not only cuts wage costs but also minimizes the risk of workplace injuries. Additionally, we will discuss how coil upenders can decrease maintenance needs through their robust design and efficiency, leading to fewer disruptions in production. By understanding the full range of benefits that coil upenders offer, businesses can optimize their operations and significantly enhance their bottom line. If you’re looking for effective strategies to improve efficiency and reduce expenditures, grasping the advantages of coil upenders is essential.

| Item | FPMT-03 | FPMT-05 | FPMT-10 | FPMT-20 | FPMT-30 | FPMT-40 |

|

Power Supply (V/Hz) |

Per requirement |

|||||

|

Power (Kw) |

1.5 | 2.2 | 3.0 | 5.5 | 10.5 | 16.0 |

|

Max. Loading (T) |

3.0 |

5.0 | 10.0 | 20.0 | 30.0 | 40.0 |

|

Table size (mm) |

Per Load size | |||||

|

Speed (sec) |

50-90 | 50-90 | 60-90 | 70-90 | 70-90 | 60-100 |

|

Machine Weight (T) |

2.2 | 2.8 | 3.5 | 4.0 | 5.0 | 6.0 |

|

Machine size (mm) |

Desinged Per Load size | |||||

| Warrantee | 24 Month | |||||

Introduction

This article will explore how coil upenders contribute to operational cost savings. We’ll examine the various ways these machines can reduce labor requirements, minimize maintenance needs, and ultimately improve your bottom line. If you’re looking to optimize your operations and cut costs, understanding the advantages of coil upenders is crucial.

1. Enhanced Labor Efficiency

With a coil upender, the need for a large labor force is drastically reduced. These machines can effortlessly lift and rotate heavy coils, allowing one operator to perform tasks that previously required a team. This reduction in manpower not only decreases payroll expenses but also minimizes the risk of worker fatigue and injury, creating a safer workplace.

Moreover, fewer employees are needed to monitor and operate the equipment, enabling companies to reallocate their workforce to other essential areas. For instance, workers who would have otherwise been engaged in coil handling can focus on quality control or other value-added processes, enhancing overall operational productivity.

2. Streamlined Workflow and Reduced Downtime

By automating the rotation and positioning of coils, these machines significantly reduce the time required for setup and changeovers. For example, instead of manually adjusting and lifting coils, operators can set the desired position and let the machine do the work. This not only speeds up the handling process but also allows for consistent positioning, which is crucial for maintaining product quality.

Additionally, coil upenders are often designed for quick operation, with intuitive controls that enable operators to make adjustments on the fly. This efficiency leads to reduced downtime, which is one of the largest hidden costs in any operation. The less time spent waiting for coils to be positioned, the more time can be dedicated to actual production, translating into higher output and reduced operational costs.

3. Lower Maintenance Requirements

Modern coil upenders come equipped with advanced materials and technology designed to withstand heavy loads without compromising performance. Their robust construction means fewer breakdowns and less frequent repairs. Additionally, many upenders feature built-in diagnostics that alert operators to potential issues before they become serious problems, further reducing maintenance costs.

The lower maintenance requirements also contribute to a longer lifespan for the equipment. Investing in a coil upender not only reduces immediate costs associated with repairs and downtime but also enhances the overall return on investment (ROI) for your machinery.

4. Energy Efficiency and Cost Savings

Many modern upenders utilize variable frequency drives (VFDs), which adjust the motor speed according to the load requirements. This means that the machine only uses the power necessary for the task at hand, rather than running at full capacity all the time. By minimizing energy use, companies can see a significant reduction in their utility bills.

Additionally, energy-efficient coil upenders often include standby modes that reduce power consumption during periods of inactivity. This feature not only lowers energy costs but also aligns with sustainability goals, making your operations more environmentally friendly.

Overall, investing in energy-efficient machinery like coil upenders can lead to substantial long-term savings, as lower energy consumption directly translates to reduced operational costs.

5. Improved Safety and Compliance

By using coil upenders, companies can ensure compliance with safety regulations and standards. Many machines come equipped with safety features such as emergency stop buttons, guarding systems, and sensors that prevent operation when safety parameters are not met. These features not only protect workers but also reduce the likelihood of costly legal issues related to workplace accidents.

Furthermore, a safer work environment can lead to higher employee morale and lower turnover rates, which are additional factors contributing to operational cost savings. When workers feel secure in their environment, they are more productive and engaged, ultimately benefiting the overall operation.

6. Enhanced Product Quality and Consistency

With a coil upender, the precision in positioning and handling coils ensures that each operation is performed consistently. This consistency not only enhances product quality but also reduces the risk of errors that can lead to waste. Improved quality translates to fewer returns and greater customer satisfaction, which can significantly impact profitability.

Moreover, consistent handling processes enable manufacturers to meet strict quality standards and certifications, further enhancing their marketability and competitive edge.

7. Reduced Inventory Holding Costs

Additionally, more efficient handling means that you can optimize your storage solutions. Coil upenders can facilitate better stacking and organization of coils, allowing for more effective use of space. This means you may need less floor space dedicated to inventory, which can reduce overhead costs associated with storage.

Lower inventory holding costs free up capital that can be invested in other areas of the business, enhancing overall financial stability.

8. Versatility Across Applications

This adaptability allows companies to minimize the need for additional specialized machinery, which can significantly reduce capital expenditures. Rather than investing in separate machines for different tasks, a single coil upender can serve multiple functions, leading to lower operational costs.

By maximizing the use of one machine for various applications, you can streamline your operations and reduce the need for extensive training on multiple pieces of equipment.

9. Long-Term Financial Investment

When evaluating the financial implications, it’s important to consider both short-term savings and long-term benefits. A coil upender will not only reduce operational costs immediately but will also contribute to long-term financial stability through reduced labor and maintenance expenses, as well as improved product quality.

Moreover, the longevity and durability of these machines mean that you’ll enjoy years of reliable service, making it a wise investment for any operation focused on sustainable growth.

10. Future-Proofing Your Operations

Whether it’s enhancing automation capabilities, integrating with smart factory systems, or adapting to different coil sizes, coil upenders provide the flexibility needed to keep pace with industry advancements. This adaptability not only safeguards your investment but also ensures that your operations remain competitive in a rapidly changing market.

By choosing equipment that can evolve with your business needs, you position yourself for sustained success and operational efficiency.

Conclusion

From energy savings and improved product quality to reduced inventory holding costs and versatility across applications, the benefits of investing in a coil upender are clear. Additionally, the long-term financial gains and future-proofing capabilities make them a strategic choice for businesses looking to optimize operations.

In a competitive industrial environment, leveraging the advantages of coil upenders can set your operation apart, ensuring that you not only survive but thrive.

I'm online now.