Click to Chat

I'm online now.

Fhopepack Innovation

AUTOMATION IN THE WIRE COIL PACKING SOLUTIONS For the steel wire industry, there are many types of wire products such as high-carbon steel wire, alloy steel wire, wire rope, stainless steel wire, Aluminium alloys wire...So the handling and packing machine need to be designed according to the production. Following machines division is based on the packaging way.

For the steel wire industry, there are many types of wire products such as high-carbon steel wire, alloy steel wire, wire rope, stainless steel wire, Aluminium alloys wire...So the handling and packing machine need to be designed according to the production.

Following machines division is based on the packaging way.

A. HORIZONTAL WIRE COIL WINDING AND STRAPPING

B. VERTICAL WIRE COIL RE-WINDING AND STRAPPING

The automatic steel wire coiling & strapping machine is able to re-winding the steel wire per length into the coil. And strapping the coil with a PP belt automatically.

The machine can be connected to the packing machine for online packaging. And it is capable offline for wire drum payoff.

The automatic wire coiling and strapping machine is able to check the length and cutting with strapping.

Steel wire coiling and packing machine for automation of the wire packaging process in steel wire production.

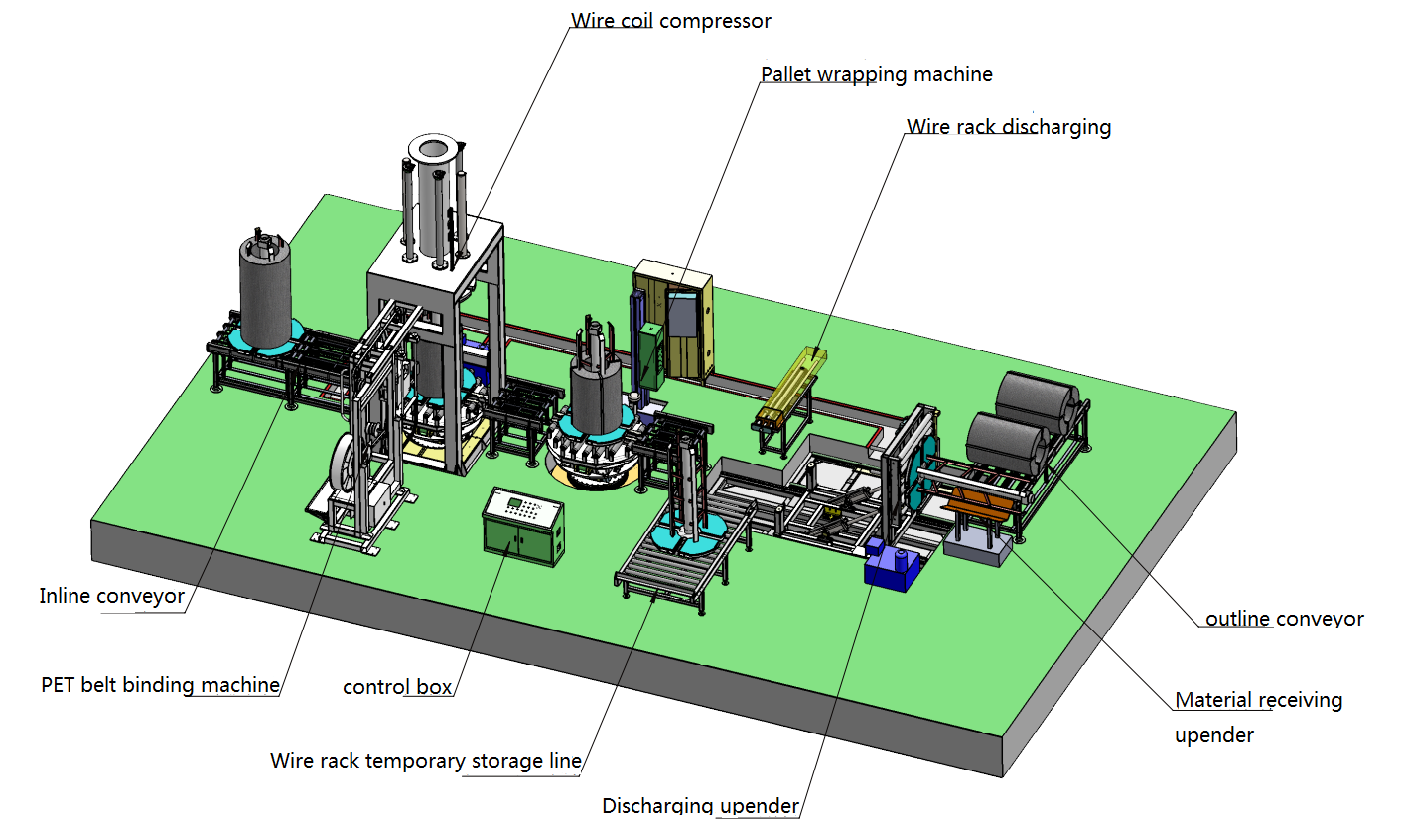

The wire coil compacting and strapping machine is normally for packing the steel wire coil with a rack. The system’s function is for compressing the wire coil and strapping it. And then take off the rack with steel wire. The rack was transferred to the production station for recycling. The wire coil will be moved from the wrapping machine to the storage area.

A. Automatic compressing and strapping machine

B. Automatic wire coil take off with a rack

It works for steel wire rod coil for wire coil wrapping with stretch film after taking off the rack in ID. The Max. Width up to 2000mm.

WIRE COIL PACKING IN VERTICAL

FOR MORE WIRE COIL PACKING MACHINE: https://www.fhopepack.com/Wire-coil-wrapping-machine/

There are machines works with different customer in different specification.

For our machine protection, we have our own process to make installation easier, and we have developed self-driven error recovery. If there is a problem inside the machine, we will let the operator enter the machine through the man-machine interface. The composition of the machine will be displayed inside, and the general scope and parts of the damage will be displayed. Operators can save a lot of time looking for damaged parts.

WIRE COIL PACKING IN HORIZONTAL

I'm online now.