Click to Chat

I'm online now.

Fhopepack Innovation

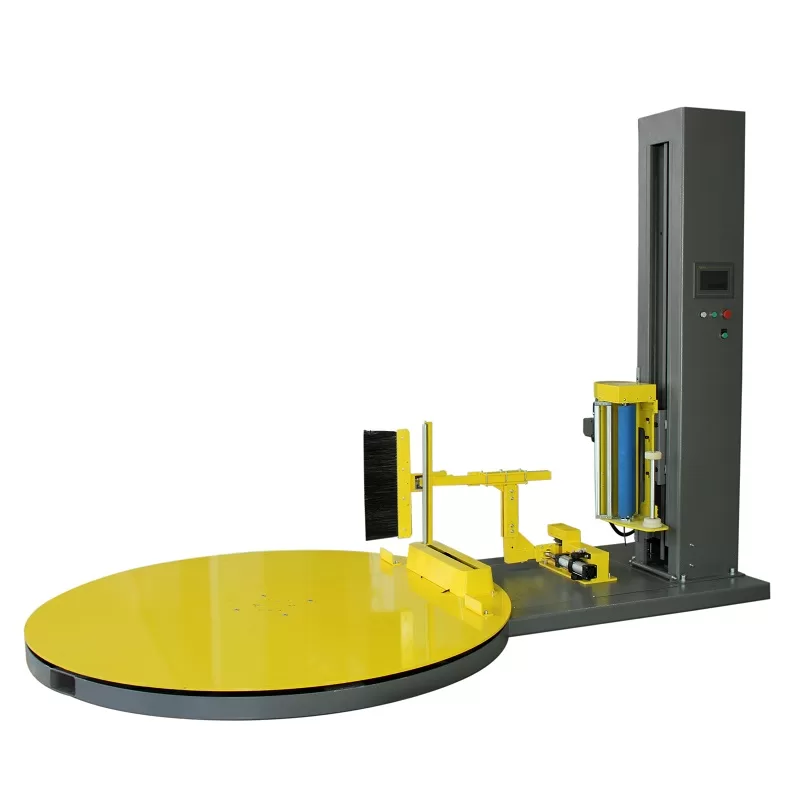

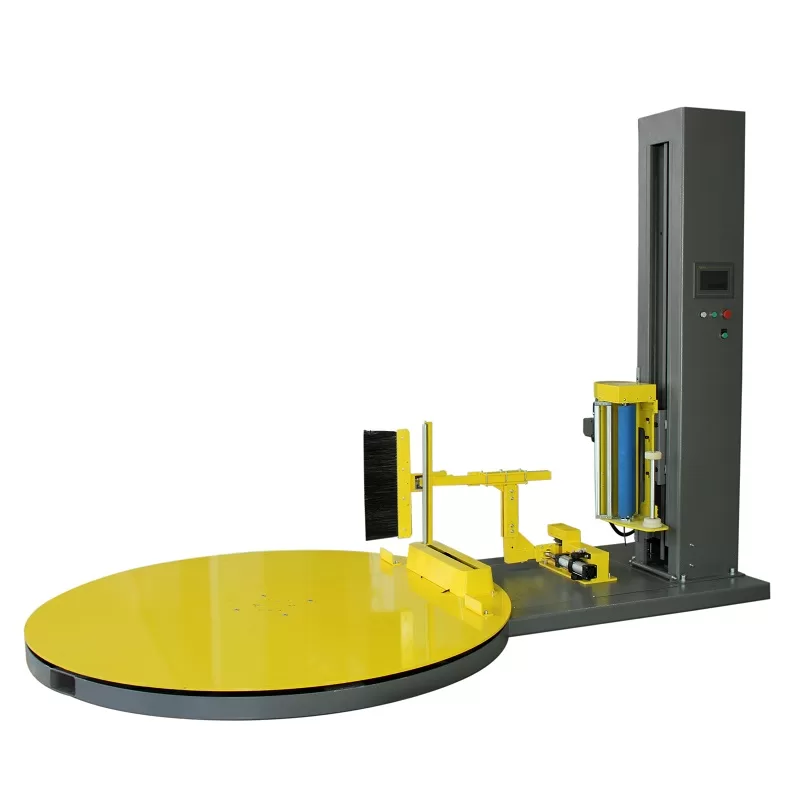

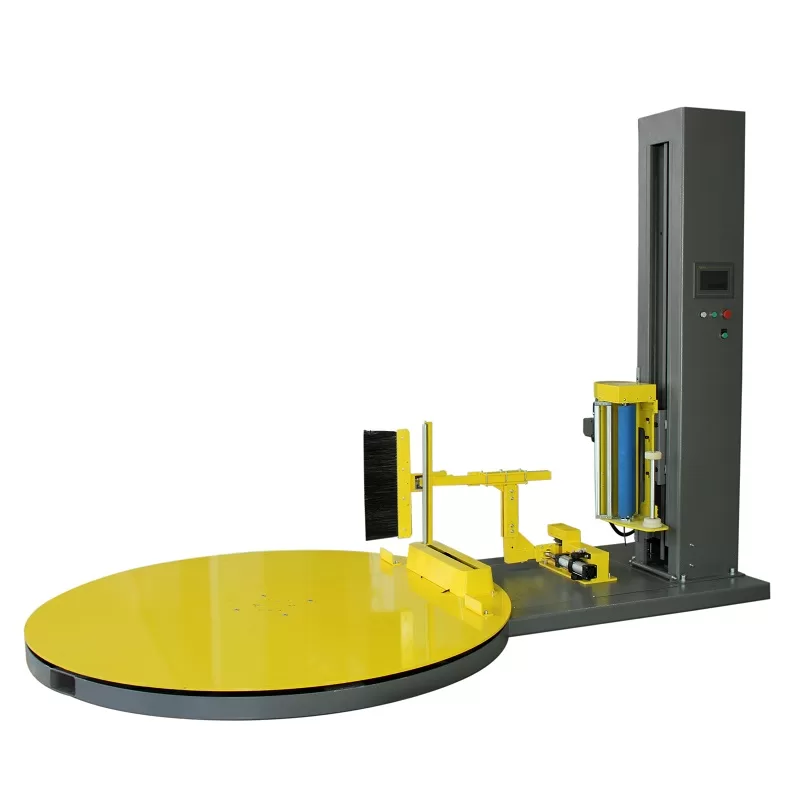

The Box Pallet Wrapper is a versatile packaging solution designed for secure and efficient wrapping of box pallets. It features advanced controls, adjustable pre-stretch ratios, and robust safety mechanisms. Built with durable materials, it ensures stability and adaptability, making it ideal for diverse industrial and logistical applications.

Manufactured by Fhope in China, the Fhope series Pallet Stretch Wrap Machine range stands out as a beacon of innovation and superior quality. It integrates the best of European engineering with cutting-edge technology, delivering unparalleled performance. Among its remarkable features, the Fhope pre-stretch system sets a new industry benchmark by significantly reducing film usage—over 50%—while maintaining exceptional wrapping quality.

Fhope's revolutionary advancements have garnered global recognition, positioning it far ahead of competitors. Let’s explore its key features and performance highlights.

Flexible Wrapping Settings:

Advanced Wrapping Options:

Portable and Customizable:

Emergency Features:

Safety Mechanisms:

Durable Design:

Reinforced Build:

Innovative Pre-Stretch System:

Comprehensive Support:

Fhope’s semi-automatic stretch wrapping machines are specifically designed for low-volume applications, efficiently handling up to 30 loads per hour. These machines are compatible with:

With its blend of advanced features, user-focused design, and exceptional performance, the Fhope Pallet Stretch Wrap Machine is a game-changer in the packaging industry. Whether you are looking to enhance efficiency, ensure safety, or reduce operational costs, this machine offers a comprehensive solution.

| Item/Data | Details |

|---|---|

| A300 | |

| MAX Load Size (L*W*H) | 1500mm * 1500mm |

| Min Load Size (L*W*H) | 500mm * 500mm * 500mm |

| Max Load Height | 1800mm |

| Max Weight | 2000kg |

| Turntable Rotation Speed | 13r/min (adjustable) |

| Turntable Diameter | 2000mm |

| Turntable Height | 100mm |

| Carriage Up/Down Speed | Adjustable |

| Power Supply Voltage (adjustable) | Standard 220 Volt 1 Ph-50 Hz |

| Tower Motor Power | 0.4w |

| Pre-Stretch Motor Power | 0.35w |

| Turntable Motor Power | 0.75w |

| Packing Efficiency | 20-40 loads/hour |

| Forklifting | Front & Rear |

| Machine Weight | 650kg |

| PLC Control | ▲ |

| Film Sealer | / |

| HMI | ▲ |

| Pre-Stretch | ▲ |

| External Diameter | 150-250mm |

| Internal Diameter | 76 |

| Film Roll Height | 500m |

| Film Thickness | 0.025mm |

I'm online now.