Click to Chat

I'm online now.

Fhopepack Innovation

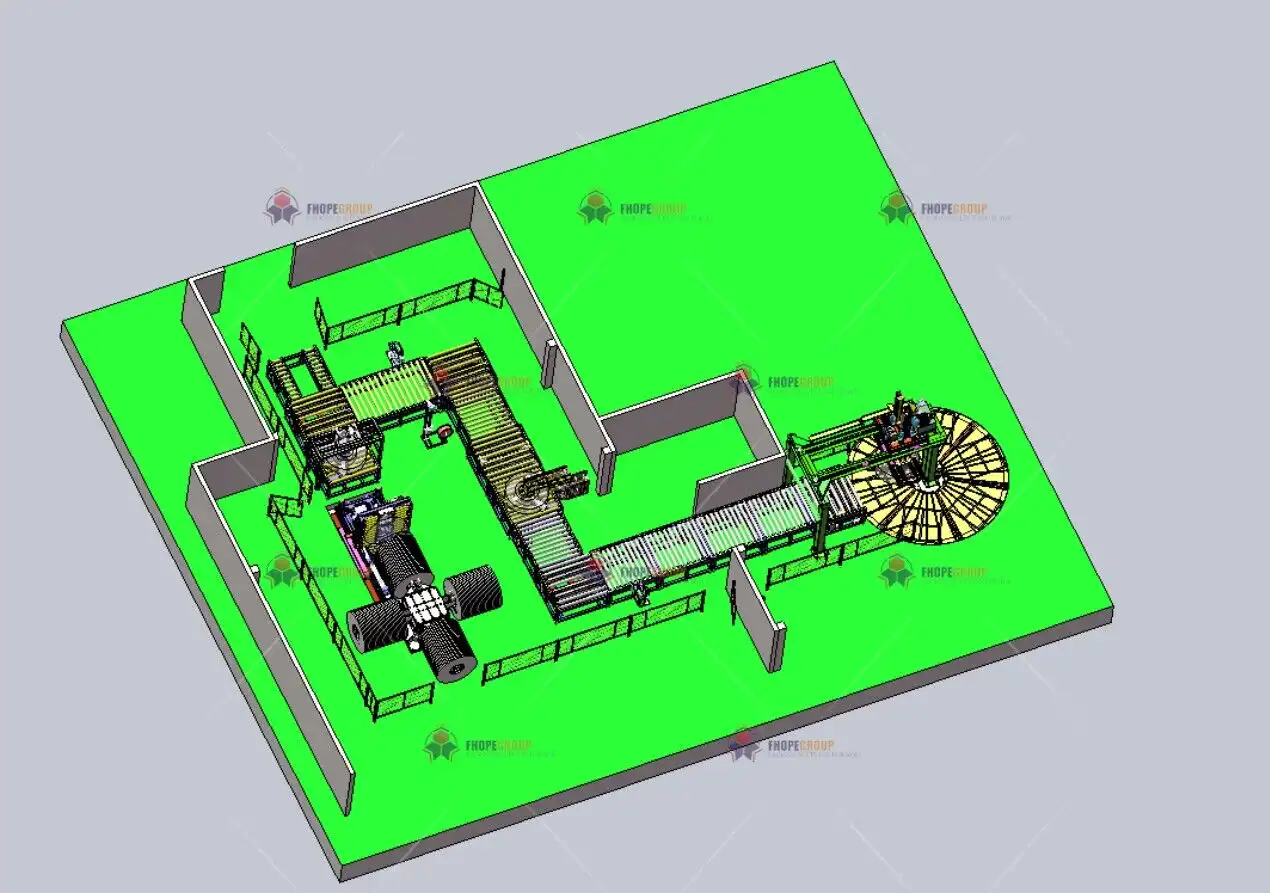

Discover the key takeaways from successful steel coil packing line projects, highlighting best practices that improve productivity and safety. This article covers essential strategies, from selecting the right equipment to streamlining processes, ensuring long-term benefits for manufacturers looking to optimize their packaging operations.

As automation tightens its grip on the shop floor, steel coil packing lines have shifted from optional upgrades to mission-critical systems. More than just a tool for streamlining workflow, a well-integrated packaging line plays a key role in maintaining throughput, minimizing damage, and keeping quality consistent—day in, day out.

But building a system that works today isn’t enough. Manufacturers now face the challenge of designing packing solutions that are not only robust and efficient but also scalable and future-ready. Successful implementations don’t just solve problems—they anticipate them.

From modular coil packing system design to integration with Industry 4.0 technologies, we look at the best practices driving real-world results. Whether you’re retrofitting legacy lines or planning a new build, these insights can help you boost productivity, reduce downtime, and stay competitive in an increasingly automated manufacturing landscape.

|

Coil parameters |

|

|

Object characteristic |

Steel coil |

|

Single coil weight |

100-4000kg |

|

Coil OD |

750-1600mm |

|

Coil ID |

508-610mm |

|

Coil width |

15-500mm |

|

Power supply |

380V-3p-50HZ |

|

Packing speed |

20-30 coils per hour |

| No. | Component Name | Model / Specification (Example) | Function Description |

|---|---|---|---|

| 1 | PLC Controller | Siemens S7-1200 / Mitsubishi FX5U | Core logic controller for the entire packing line |

| 2 | HMI Touch Screen | Siemens KTP700 / Weinview TK6070 | Operator interface for monitoring and parameter settings |

| 3 | VFD (Variable Frequency Drive) | Danfoss VLT2800 / Delta VFD-E | Motor speed control for soft start/stop and energy efficiency |

| 4 | AC Contactor | Schneider LC1D / Siemens 3RT | Motor start/stop control and load switching |

| 5 | Thermal Overload Relay | Schneider LRD / Siemens 3RU | Protects motors from overload or phase failure |

| 6 | Switching Power Supply | MeanWell 24V 10A | Stable DC power source for control units and sensors |

| 7 | Safety Relay | PILZ PNOZ / Omron G9SP | Ensures safety circuit operation, emergency stop, and interlocks |

| 8 | Photoelectric Sensor | Sick WT18 / Omron E3Z | Detects coil position and enables auto positioning |

| 9 | Proximity Sensor | Omron E2E / Schneider XS | Senses metal targets or travel limits |

| 10 | Encoder | Omron E6B2-C / Koyo TRD Series | Provides feedback on speed, rotation, or length |

| 11 | Intermediate Relay | Finder 55.34 / Omron MY4 | Signal isolation and relay logic control |

| 12 | Servo Drive & Motor | Delta ASDA-B2 / Yaskawa Sigma-7 | High-precision motion control for wrapping arm or ring rotation |

| 13 | Relay Terminal Modules | Weidmüller / Phoenix Contact | Centralized signal control and wiring management |

| 14 | MCCB Circuit Breaker | Schneider NSX / ABB Tmax | Main and sub-circuit overload/short-circuit protection |

| 15 | Control Buttons & Indicators | Schneider Harmony / IDEC | Manual control for start, stop, reset, fault display, etc. |

| 16 | Communication Module (Optional) | Profinet / Modbus / Ethernet/IP | For connecting to MES/ERP systems, enabling remote monitoring and data exchange |

| 17 | Temperature Controller | Omron E5CC | For regulating heating elements in shrink wrap stations |

| 18 | Safety Light Curtain (Optional) | Sick / Keyence GL-R Series | Personnel safety to prevent access during machine operation |

| 19 | UPS (Uninterruptible Power Supply) | APC / Delta | Maintains power for PLC/HMI during outages to ensure data safety |

| 20 | Cables & Terminal Blocks | LAPP / Phoenix Contact | Power and signal transmission with reliable connections |

Brand Consistency: Use components from the same manufacturer where possible to ensure compatibility and easier maintenance.

Voltage Levels: Typical control voltage is 24VDC; motor and drive voltage is 380VAC (three-phase).

Redundancy: For critical systems, consider backup PLCs or power supplies.

Safety Compliance: Ensure system meets at least SIL2 / PLd safety standards.

As the manufacturing landscape evolves, steel coil packing have become indispensable for ensuring efficiency and consistency in production. With the increasing demand for automated solutions, successful implementations are not just about addressing current needs but also planning for future scalability and integration with cutting-edge technologies. This article will explore the best practices that have emerged from successful steel coil packing line implementations, offering insights into how businesses can optimize their operations and future-proof their investments.

When setting up a steel coil packing line, the initial design phase is critical. Companies that have experienced success in their implementation often start with a detailed strategic plan. This plan not only addresses the immediate needs of production but also considers long-term objectives such as automation integration, capacity expansion, and equipment upgrades.

By creating a roadmap from the beginning, businesses can avoid unnecessary costs and disruptions in the future. Strategic planning ensures that every aspect of the packing line — from the placement of machines to their functionality — aligns with the company’s overall goals.

One of the most significant lessons learned from successful steel coil packing line implementations is the need to design for future automation integration. The fourth industrial revolution, also known as Industry 4.0, emphasizes the integration of smart technologies and automated systems into manufacturing. To ensure a long-lasting and future-proof solution, companies must design their packing lines with this in mind.

Industry 4.0 involves the integration of digital technologies such as the Internet of Things (IoT), artificial intelligence (AI), and real-time data analytics into the manufacturing process. These technologies enable machines to communicate with each other, monitor performance in real-time, and optimize operations without human intervention.

For a steel coil packing line to remain competitive, it must be designed to integrate these technologies seamlessly. By incorporating sensors, PLC systems, and cloud-based monitoring platforms, the machines can become part of an interconnected network, improving efficiency and reducing downtime.

Designing a steel coil packing line that is ready for future automation requires careful consideration of several factors:

To prepare for Industry 4.0 integration, the machines in a steel coil packing line must meet specific technical criteria:

By considering these factors during the design and implementation phase, businesses can ensure that their steel coil packing lines will not only meet today’s production demands but also be ready for tomorrow’s challenges. The ability to seamlessly integrate Industry 4.0 technologies will enable faster production, more reliable operations, and ultimately, a higher return on investment (ROI).

The wrapping machine is one of the most critical components of a steel coil packing line. Its role in protecting steel coils during transport and storage cannot be overstated. Selecting and setting up the right wrapping machine requires attention to both technical specifications and the future needs of the business.

To ensure that the wrapping machine integrates seamlessly with future technologies, it's essential to select models that are IoT-enabled and equipped with smart sensors. These machines will be able to collect and analyze performance data, contributing to predictive maintenance strategies and reducing downtime. Furthermore, IoT-enabled machines allow remote monitoring and troubleshooting, which is crucial for Industry 4.0 operations.

A reliable strapping machine is essential for securing steel coils after they have been wrapped. Proper strapping ensures that the coils remain intact during transportation, preventing damage and minimizing the risk of accidents during handling. Optimizing the strapping machine for long-term use and future automation is another critical element in minimizing downtime.

Similar to the wrapping machine, a strapping machine should be PLC-controlled and capable of data communication via IoT. Advanced models also offer automated strapping material feeds, reducing human intervention and keeping the line moving smoothly.

For businesses anticipating growth, it’s wise to invest in modular strapping machines that can easily be upgraded or expanded to accommodate increased production needs.

After the coils have been wrapped and strapped, the coil stacking machine plays a vital role in arranging them for storage or shipment. Without a reliable stacking solution, the risk of damaging coils or creating unsafe work conditions increases.

As with the other machines on the line, the stacking machine should be designed with Industry 4.0 integration in mind. This means incorporating real-time monitoring capabilities, such as cameras and sensors, to ensure the coils are stacked correctly and without the risk of instability. Additionally, data collected from these machines can provide valuable insights into optimizing storage space and reducing time spent on manual stacking operations.

While automation can significantly reduce human intervention, it is still critical that operators and maintenance teams are properly trained on how to run and troubleshoot these sophisticated systems. Regular training programs not only ensure that your team is equipped with the knowledge to handle the current technology but also prepare them for future upgrades and integrations.

One of the most important strategies for reducing downtime is the implementation of a predictive maintenance program. Predictive maintenance uses data collected from IoT sensors and machine monitoring systems to predict when a machine is likely to fail, allowing for preemptive repairs before a breakdown occurs.

Implementing a predictive maintenance system ensures that the packing line remains operational, minimizing costly unplanned downtime and extending the life of your machines.

Many businesses have successfully implemented steel coil packing lines and reaped significant benefits, not just in terms of increased efficiency but also in cost savings and reduced downtime. For instance:

These examples demonstrate the tangible benefits of planning for future automation and investing in robust, flexible solutions that can grow with your business.

One of the major benefits of investing in automated packing lines is the long-term return on investment. While the initial setup costs may be significant, the savings generated through increased efficiency, reduced labor costs, and minimized downtime quickly offset these expenses.

Companies that invest in future-ready automated systems will find that their ROI continues to improve over time as their machines evolve with Industry 4.0 capabilities.

In conclusion, successful steel coil packing line implementations are not just about meeting today’s production demands. Businesses must also plan for the future by designing systems that can integrate with Industry 4.0 technologies and scale as production needs increase.

By focusing on key elements like modular designs, IoT integration, and predictive maintenance, businesses can minimize downtime, increase efficiency, and ensure that their investments provide a long-term return. Moreover, ongoing operator training and a commitment to future automation will help companies stay competitive and prepared for the next wave of technological advancements in manufacturing.

Ultimately, investing in a future-proof steel coil packing line ensures that your business is well-positioned for continued success in a rapidly changing industry.

I'm online now.