Click to Chat

I'm online now.

Fhopepack Innovation

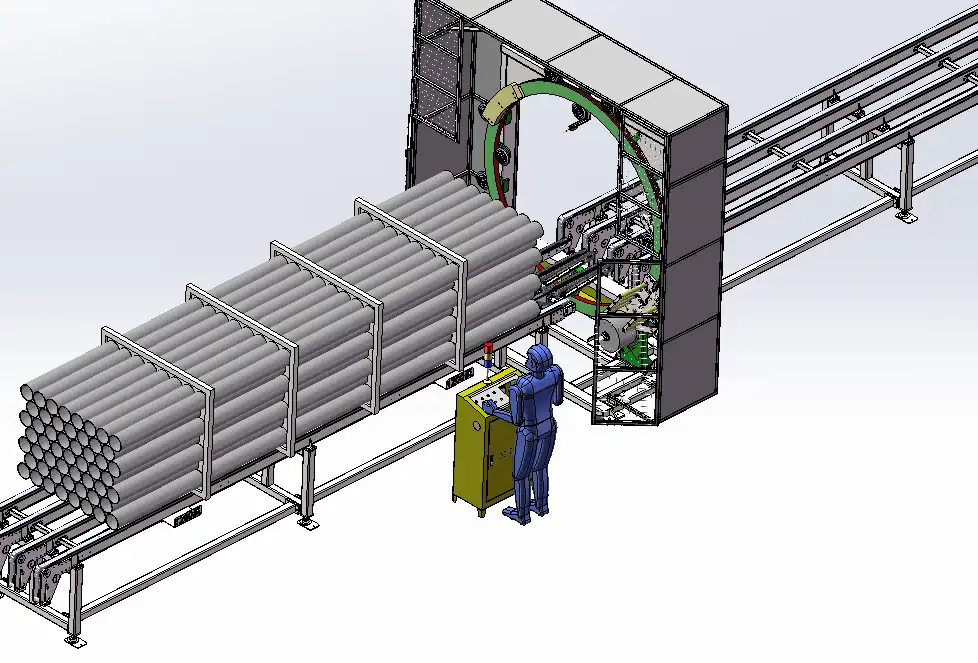

The horizontal pallet wrapping machine automates the process of wrapping pallets with stretch film, providing consistent and secure packaging. It enhances productivity, reduces the risk of damage during transportation, and ensures cost-effective use of materials. Suitable for diverse industries, this machine streamlines pallet packaging and improves overall efficiency.

With the rise in demand for warehouse automation, many businesses are now turning to horizontal pallet wrapping machines to optimize their packaging workflows. These machines are designed to handle large volumes of goods, offering consistent and reliable wrapping that reduces human error and increases efficiency. By integrating such technology, companies can significantly lower labor dependency, improve packaging speed, and enhance overall operational accuracy. As a result, horizontal pallet wrappers are revolutionizing how warehouses manage their packaging processes, enabling smoother, more secure transportation of goods while minimizing costly mistakes.

|

Object size |

Length:>800mm Bundle OD:200-600 Weight:20-200kg |

|

Infeed conveyor |

2000mm L×800mmW |

|

Outfeed conveyor |

2000mmL×800mmW |

|

Material |

LLDPE stretch film/ Paper/ Woven Width: 150-300mm OD: 100-250mm ID: 50mm (Let me know, if you need another size) |

|

Air Supply |

5~8kgf/cm2 |

|

Conveyor Speed |

3~12m/min |

|

Ring speed |

App. L5200 x W1800 x H1800mm |

|

Power output |

about 4.5kw |

|

Power voltage |

AC 380v,50Hz,3Phase |

|

Control Power voltage |

ADC24V

|

In today's fast-paced warehouse environments, efficiency and reliability are critical factors for maintaining competitive operations. The horizontal pallet wrapping machine plays an essential role in automating packaging processes, helping businesses enhance productivity, minimize labor costs, and ensure the secure transportation of goods. With the increasing demand for automation, many warehouses are turning to this technology to optimize packaging workflows and reduce human intervention. In this article, we'll explore the benefits, features, and key considerations of horizontal pallet wrapping machines and how they are revolutionizing warehouse packaging automation.

A horizontal pallet wrapping machine is a specialized piece of equipment used to wrap products with stretch film for added protection during storage and transit. Unlike traditional vertical wrapping machines, horizontal wrappers operate on a horizontal axis, making them ideal for securing elongated products or large bundles that may not be easily wrapped by conventional methods. These machines are widely used in industries ranging from logistics and warehousing to manufacturing and distribution, offering robust, reliable solutions for fast-paced environments.、

Manual wrapping can be time-consuming, inconsistent, and prone to errors. For warehouses dealing with high volumes of goods, automating the packaging process is a game-changer. Automated pallet wrapping machines streamline the process by reducing the need for manual intervention, ensuring uniform wrapping, and minimizing material waste. These machines also significantly increase the throughput of packaging operations, allowing businesses to meet tight deadlines and reduce bottlenecks in production or distribution lines.

Key benefits of warehouse packaging automation include:

Horizontal pallet wrapping machines function by rotating stretch film around a horizontally placed product. As the product is fed through the machine, the wrapping arm moves around it, tightly securing the stretch film. This wrapping process is suitable for products like lumber, pipes, and long bundles, as well as for pallets with unevenly shaped loads.

The key steps in the operation of a horizontal pallet wrapper include:

When selecting a horizontal pallet wrapping machine, it’s essential to consider specific features that will enhance the efficiency and versatility of your packaging line. Some of the most important features include:

The introduction of horizontal pallet wrapping machines into warehouse automation offers several transformative benefits. These machines are designed to tackle the common challenges warehouses face in handling and securing large, irregularly shaped loads. Here are some of the standout benefits:

While both horizontal and vertical wrapping machines serve similar purposes, they are designed for different types of products and workflows. Vertical wrapping machines are ideal for standard pallet loads and smaller items, while horizontal machines are better suited for elongated or irregularly shaped goods.

Choosing the right machine depends on the types of products you handle in your warehouse. If your inventory includes a mix of regular and irregularly shaped items, integrating both vertical and horizontal machines may provide a comprehensive solution.

In a fully automated warehouse, horizontal pallet wrapping machines can be integrated with Warehouse Management Systems (WMS) for seamless operations. A WMS allows for better coordination between packaging machines and other warehouse functions, such as inventory management and shipping. This integration enhances productivity by ensuring that wrapping operations align with the broader logistics workflow.

With real-time data from WMS, pallet wrapping machines can be adjusted for different product types, load sizes, and shipping requirements, providing maximum operational efficiency.

One of the critical goals in warehouse automation is to minimize downtime, and horizontal pallet wrapping machines excel in this area. By automating the wrapping process, businesses can reduce human error and inefficiencies that often cause delays. Additionally, these machines are built for durability and continuous operation, allowing warehouses to maintain high throughput without frequent breakdowns.

Regular maintenance and having the right machine for your operation are essential steps to ensuring smooth performance and preventing costly downtime.

Not all warehouses have the same packaging needs, which is why customizable wrapping solutions are so important. Many horizontal pallet wrapping machines offer modular designs, allowing businesses to configure the machine according to their specific operational requirements. Customization options include:

The adoption of horizontal pallet wrapping machines in warehouses is more than just a trend—it’s becoming a necessity for operations looking to scale efficiently. These machines not only save time and reduce labor costs but also ensure that products are securely wrapped and ready for transport with minimal risk of damage. As automation technology continues to evolve, we can expect horizontal pallet wrappers to become more integrated with smart systems, enhancing overall warehouse productivity and safety.

By investing in an automated wrapping solution, businesses can future-proof their operations, reduce material waste, and ensure the seamless flow of goods through the supply chain.

I'm online now.