THE SHOW CASES ABOUT THE HANDLING EQUIPMENTS

Handling equipment for load refers to any machinery or tools used to move, carry, or transport heavy items or loads. Examples include cranes, forklifts, conveyors, pallet jacks, hoists, dollies, and hydraulic lift tables. These devices are used in many different industries and settings, including construction sites, warehouses, manufacturing facilities, and shipping docks, to make it easier and safer to move heavy loads.

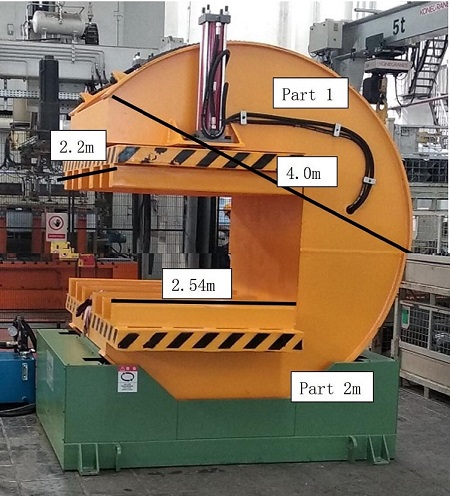

The handling equipment meet the engineering turnover requirements of goods of different specifications, and can safely, stably and effectively carry out process transportation. The whole application covers metallurgy, stamping, sheet metal, mould, paper making, refrigeration, steel strip, coil, barrel material, etc., so as to realize the operation goal of converting goods from horizontal to vertical or vice versa.

General Features

1. The equipment is operated by remote control, so it can not slip or rotate backwards when turning over large objects.

2. It has the function of rotating the workpiece, the angle can be according to the customer's requirements, and has the characteristics of simple operation, flexible and reliable use.

3. The equipment is controlled by remote control, so that the operator can remotely control the turnover, and it has the characteristics of easy turnover with light lifting and light falling.

4. The equipment has the characteristics of light weight and flexible movement, and can be turned over by moving the equipment to the site where the workpiece is suspended and turned over without moving large workpieces.

Handling Equipments

-

Board and panel upender for MDF| Sandwich | woodenBoard and panel Upender for MDF Brief Introduction: A heavy Capacity load inverter was created to rotate a maximum load of 5 tons by 180 degrees. Its design includes a durable hydraulic cylinder to press and fix production position to ensure safety and facilitate a smooth. The power motors robustness allows it to handle heavy loa...

-

Tilting table for flat precast concrete elementsTilting tables are integral to producing large, level precast concrete elements efficiently. The ground table surface ensures an optimal finish. Shuttering forms of various sizes create openings for doors and windows. High-frequency vibrators compact wet concrete thoroughly. Heating systems can accelerate curing. Hydraulic tel...

-

Moldtech tilting tables for precast manufacturersAn ideal surface requires grinding the table. Shuttering forms in diverse sizes and thicknesses facilitate elements with openings for doors and windows.High-frequency vibrators compact freshly poured concrete. Heating systems expedite curing by fitting the table.Hydraulic telescoping cylinders tilt the table, enabling safe, secur...

-

Mold Rotator | for mould and Die handlingA mold rotator rotates molds controllably for manufacturing processes. It casts, forms or shapes materials into desired shapes by pouring into molds until set.Steady, consistent rotation distributes materials uniformly, resulting in more uniform, consistent finished products. The rotator enables economical production of high-qual...

-

Mold Upender machine 5TA mold upender inverts molds precisely for filling and sealing. It handles heavy loads with care and control. Mold upenders expedite manufacturing by automating a manual process. They flip molds swiftly yet steadfastly for efficient, consistent work. Uprighting molds as quickly and steadily as overturning them, upenders minimi...

-

Tipper on stockCOIL TIPPER FOR SALE FHOPE is responsible for the design and manufacture of the vertical one-piece turning equipment and performs all manufacturing processes and commissioning steps. Fhope's main business is to provide packaging equipment for the steel industry, construction industry, and food and beverage can industry.Steel cons...

-

Die flipper for Die and mouldDie flippers invert molds swiftly and surely without damage. Two versions assist in handling and flipping heavy molds up to 60 tons: 180-degree flippers and hydraulic systems. 180-degree flippers flip molds 180 degrees, minimizing contact. Hydraulic systems harness pressurized oil to flip, rotate or tilt molds up to angles for...

-

Die&mold flipperMold flipping upenders invert molds rapidly yet carefully, enabling material pouring and sealing. They handle heavy loads, up to 60 tons, with precision, accuracy and ease, ensuring worker safety. Two versions facilitate mold flipping: 180-degree and hydraulic upenders. 180-degree upenders flip molds 180 degrees for minimal cont...

-

Precast slab upenderA precast slab upender flips slabs rapidly yet carefully, expediting installation while preserving safety. It handles large, heavy slabs, improving a manual process prone to injury or damage. Manual slab flipping proves perilous and time-consuming. Upenders transform this through automation, delivering economical efficiency a...

-

Steel sheet upenderThe steel sheet upender and tilter is a crucial machine in the steel industry. It features a C-shaped turnover body that is motor-powered to flip piled steel sheets up to 180 degrees. To load the products, a forklift is required. The machine can also be adapted to a semi-submersible layout, where it is placed in a pit on the floo...

-

Mobile pallet turnerThe Fhope mobile pallet inverter is a highly useful equipment for warehouse handling. It is designed for easy movement and tilting of pallets with the help of a hydraulic cylinder that can handle heavy loads. The machine allows for manual rotation and pallet change, which enhances workers' efficiency. Its reinforced structure and...

-

customized hydraulic upenderThe hydraulic upender features a U-shaped saddle and a powered conveyor. It is specifically designed for indoor applications, with various models available that differ in capacity, lift height, and platform size. While all models share a similar design, each is tailored to meet the specific needs of different customers. Whether y...

-

manual drum upenderThe manual drum upender is a customized mechanical upender that comes equipped with tie-down bars to secure molds during the upending process. Its extra-wide platform is designed to accommodate larger loads, making it a versatile solution for a wide range of industrial applications. With its innovative design and reliable perform...

-

china roll upenderWhen looking for a Chinese manufacturer of upenders, it is crucial to conduct thorough research and compare different companies to find the best fit for your needs and budget. Factors to consider include the quality and durability of the machinery, the level of customer service and support provided, and the reputation of the comp...

-

up ender machineLoad upenders are available in various structures and driving mechanisms that are customized to fit specific load sizes, shapes, and moving tools or kits. To ensure that the machine is designed to meet the user's needs, it is essential to provide all necessary information during the communication and purchasing process. This step...

-

Chinese coil tilter manufacturer / Upender / steel coil/Companies that specialize in handling and processing steel coils typically offer a variety of machinery, such as coil tilters, cranes, and other material handling equipment. In addition to these standard products, they may also provide customized solutions to meet specific customer requirements. With their expertise in the indust...

-

china mechanical upendersThe China coil tilter is fully electrically controlled, with an isolating switch and button station mounted on the unit. To ensure safety, lift the platform and disengage the maintenance safety bar. The limit switch automatically controls rotation. Before use, it's crucial to wear protective equipment, follow manufacturer instruc...

-

mechanical upendersWhether you need a standard configuration or a custom-engineered solution, mechanical upenders are versatile tools for your application. For floor applications, use the chalk line on the platform to measure hoist position. Heavy-duty, welded steel construction forms the frame, while four or more precision machined steel rolls wit...

-

customized coil upenderOur customized coil upenders are tailored to meet your unique needs and requirements. From specific load capacities to handling coils of a particular size or shape, we design the features you need. Our specialized features ensure that your application is handled with precision and efficiency. Trust us to deliver a customized solu...

-

customized coil upendersThe upender provided to lift coil material typically comes with a V-bracket mounted on one of the platforms. This cradle supports the circular cross-section material and prevents lateral rolling when in a horizontal position. For units used at the lower end, the platform serves as the offload platform. Those without a V-bracket c...

-

customized roll upenderOur roll upenders come in different versions for handling paper, carpet, curtain, and other rolls. Depending on the factory, there may be various ways to shift the roll position from the production line to the workhouse or to load and unload from storage or cars. Regardless of your handling needs, our roll upenders provide the ve...

-

customized upenders tiltersAn upender (also known as a tilter or a coil upender) is a machine that is used to rotate heavy or awkward objects from a horizontal position to a vertical position. They are commonly used in the manufacturing and processing industries to facilitate the handling, storage, and transportation of materials such as steel coils, drums...

-

hydraulic upenders manufOur hydraulic upenders are adaptable to various systems and feature automatic operation for molds, rollers, coils, and more. We offer two types of upenders: mechanical and hydraulic. Choose from our selection of hydraulic upenders to find the perfect solution for your application. With reliable performance and easy operation, our...

-

used coil upendersOur upenders are a versatile solution for both production and maintenance applications, with multiple options available to customize them to your specific needs. Choose between our two types of upenders, mechanical and hydraulic, to find the ideal fit for your operation. With our reliable and efficient upenders, you can optimize ...

-

low price coil upender tilterOur hydraulic upender platforms are designed to handle a diverse range of load configurations, including long loads like paper rolls or other materials with a length significantly greater than their width or diameter. With our upender platforms, you can efficiently and safely handle your unique loads, no matter their shape or siz...

-

china movable coil upender tilterOur high-quality double-acting tilt cylinders efficiently rotate the platforms, powered by an industrial-duty motor, hydraulic pump, valve system, and oil reservoir. These components are expertly embedded within the unit or packaged for external mounting, ensuring reliable and efficient operation. With our tilt cylinders, you can...

-

customized hydraulic coil upenderA hydraulic coil upender is a machine that uses hydraulic cylinders to lift and rotate coils of material, such as steel or aluminum, from a horizontal position to a vertical position. They are typically used in the manufacturing and processing industries to facilitate the handling, storage, and transportation of these materials.W...

-

mechanical upenderOur mechanical upenders, also known as coil positioners, offer efficient rotation of steel coils and other loads up to 90 degrees in either direction. We offer two types of upenders, mechanical and hydraulic, to ensure that you have the best solution for your application. With our mechanical upenders, you can optimize your produc...

-

hydraulic upenderA hydraulic upender (also known as a hydraulic tilter or hydraulic coil upender) is a machine that uses hydraulic cylinders to lift and rotate heavy or awkward objects from a horizontal position to a vertical position. They are commonly used in the manufacturing and processing industries to facilitate the handling, storage, and t...

-

coils tiltersOur upenders offer versatile solutions for both production and maintenance applications, and are customizable with a range of options to suit your unique needs. Choose between our two types of upenders, mechanical and hydraulic, to find the best fit for your operation. Check out our related pictures, including upender/tilter + co...

-

customized coil tilterWe offer a range of steel coil tilters, each with their own customized services and comprehensive technical support. Choose from our professional mold tilters or mechanical coil tilters with customizable services, or opt for our coil upender with turntable rotary tilter. We also offer hydraulic 90 coil tilters with adjustable wor...

With most Upender models, there is no requirement to set up a pallet rack. Actually set up the base rack, lock the load up and put the pallets on top of the coils. Some models of load upenders even showcase swing round wheels for simple transportation of supplies between workplaces. Pallet racks can be an exorbitant business tool, because they enhance productivity and make better the efficiency for carring the load from one station to another station

There are numerous tools and resources obtainable to aid with distinct ways to enhance worker safety by fetching routine audits and scheduling for betterment. One way to make better the safety is the usage of raising help which are recorded among the top foolproof best practices since the equipment lessens the requirement for lifting, turning, twisting, and bending. There are many famous lifting aids for example forklifts, hoists, scissor lifts, tilters, stackers, conveyors, pallet trucks, etc. But are you accustomed with the Upender?

Coil Upenders serve to enhance the line speed by letting an operator to load a coil onto a spinning pallet earlier to spin the coil over a stationary deck. This device also enhances line speed by refreshing an operator to pre-stretch coils while the decrator is operating, by doing so lessening the contact time between the coils. These devices are important for preparing large quantities of materials for instance loose materials, rolled products, and other specialty items. Maximum Coil Upenders are configurable and add on a programming facility that permits you to set the settings for all operation kinds. Numerable models let the users to choose from many operating modes, which comprises of ceaseless Run, Slip, and Repeat.

The very popular sizes of Upenders are those that are amid handling the mold, steel coil, pallet...and that have in the the spefication deck load capacity. Over and above that, maximum load Upenders attributes the alternatives of working table form per handling tools.

Product Inquiry

![]() Email: [email protected]

Email: [email protected]

![]() Whatsapp: 0086-13951501635

Whatsapp: 0086-13951501635