Click to Chat

I'm online now.

FHOPEPACK is one of leading manufcuterer for pallet invereter and pallet changing machines in China. The pallet inverter equipments manufactured by Fhone Group, is used to change or remove the pallet from the bottom of the load. Our pallet changer is designed with different types in order to be suitable for different loads. This machine can be used in the whole process of touch operation without human involvement. The pallet inverter will meet the customer's different needs from the stack heights, pallet size and weight. The strong structure and clamper ensure the pallet is stable in changing process. Some model equipped with side clamping maintains the integrity of the load. For meeting the EU standard, there is totally automated system with fancy guarding or light barriers. Our team provides customized solution and modification services. Hope to give you the perfect service by the design and manufacture of our pallet inverter.

The pallet inverter is designed to load pallet loads onto the inverter base using a forklift, with faster turning speeds and easy operation. The 180° Pallet Inve...

The lower clamp on this pallet inverter is designed to touch the ground, making it workable with a pallet jack and suitable for workplaces that do not have a fork...

This machine is designed with two clampers, making it faster and more efficient than ever before. Its strong energy support system enables it to handle large and ...

This pallet handling machine boasts a classic design that is both high quality and cost-effective, making it a popular choice in the market. Its strong structure ...

Heavy load reclining pallet inverter With heavy load recline pallet inverter you can quickly and easily change the pallet from a load or replace a broken pallet t...

The pallet inverter is an efficient floor-level handling machine designed for pallet handling. This equipment is constructed with high-quality components from wel...

The Pallet Inverter with two clamps is designed for heavy pallet load handling, with a capacity of up to 2T. The specific models of pallet inverters may vary in t...

The mobile pallet changer is a versatile pallet handling equipment that can handle up to 1000kg, with the ability to handle, turn, and change pallets. It provides...

The mobile pallet changer is a versatile handling equipment that is used to change pallets in a variety of applications. It is designed to be powered by a battery...

Mobile pallet inverters are specialized handling equipment that are used to rotate or flip pallets for various purposes, such as for loading or unloading goods on...

The Mobile Pallet Changer - Side Press offers a dynamic solution for seamless pallet transfers. This device employs lateral pressing technology to secure products...

This hydraulic pallet exchanger rotates pallets 95 degrees for easy pallet changing. Driven by a high-quality hydraulic system with international brand components...

This floor-level pallet changer rotates pallets 95 degrees for removing and changign the pallet on bottom. From a leading manufacturer, this heavy-duty pallet cha...

For operator safety, the pallet changer isolates the load handling process from the operators. It uses a V-shaped design and scissor-lift mechanism to securely cl...

The heavy-duty pallet changer is designed for handling large pallets of goods. Ideal for industrial warehouse environments handling heavy loads, it enables effici...

Fhope Group offers a high-performance pallet changer that uses a pushing method to smoothly change pallets without the need to rotate them. Ideal for high-volume ...

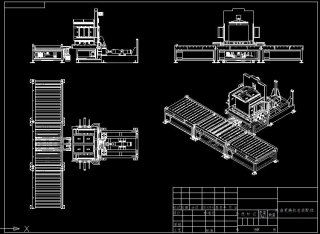

Our online pallet handling equipment is designed for automatic in and out control, offering a customizable and efficient solution for businesses seeking reliable ...

Our online type pallet handling equipment is designed to connect to different automation lines, providing a seamless and efficient pallet handling process without...

The Toppy Master Inverter Logy is an automated pallet changing system that features a linear pallet changer, enabling gentle pallet replacement without the need f...

We offer ODM services for pallet changing systems that can be connected to MES for IoT information sharing and management. Our inline pallet changers are high-per...

A high-speed automatic pallet changing line streamlines material handling processes by efficiently swapping pallets without manual intervention. Ideal for industr...

This Online 180° Pallet Changer is an ideal solution for Kalesi Technology, combining reliability, efficiency, and flexibility. With premium components and cutti...

The key reason is efficiency and operational compatibility. Different handling methods require specific equipment to optimize performance, ensure safety, and reduce manual labor. Choosing the right pallet inverter tailored to your handling way can make a significant difference in productivity and cost-effectiveness.

Here's why:

Hand Hydraulic Tool for Floor-Level Operation:For manual handling at ground level, a pallet inverter designed for hand hydraulic tools ensures simple, straightforward operation. This is ideal for smaller-scale operations where space and budget constraints are critical.

Forklifter Integration: If forklifts are part of your workflow, a pallet inverter compatible with forklifter operations allows for smoother, faster handling. It minimizes the risk of product damage and boosts throughput for medium to large-scale operations.

Conveyor Online In & Out Feeding: For automated or semi-automated systems, a conveyor-compatible pallet inverter streamlines processes, enabling seamless in-feed and out-feed handling. This is crucial for high-volume operations where continuous material flow is essential.

Matching your pallet inverter to your handling method ensures optimal performance, minimizes downtime, and supports long-term operational efficiency.

》By Manually

》By Crane

》By Conveyor

》By Forklifter

Selecting the right pallet inverter involves evaluating specific operational requirements to ensure compatibility, efficiency, and safety. Here are the essential factors to keep in mind:

Load Size (Min & Max Dimensions): Understand the range of load sizes your pallet inverter needs to handle, including the minimum and maximum length, width, and height. This ensures the machine can accommodate a variety of products without risking instability or inefficiency.

Maximum Weight Capacity: Determine the heaviest load the pallet inverter will need to manage. Overloading can compromise safety and damage the equipment, so selecting a model that supports your maximum weight requirement is critical.

Working Environment: Assess the operational environment, including temperature, humidity, and cleanliness. For example, harsh industrial settings may require a rugged, heavy-duty machine, while food or pharmaceutical industries might prioritize hygiene and corrosion resistance.

By considering these factors, you can select a pallet inverter that aligns with your specific needs, enhances operational efficiency, and ensures long-term reliability.

Safety is a top priority when selecting and operating a pallet inverter. To minimize risks and protect both workers and products, consider these essential safety features:

Safety for operation: With Fencing and Light Beams, Modern pallet inverters often come equipped with safety fences and light beams to create a secure working zone. These barriers prevent unauthorized access to the operating area and automatically halt operations if a person or object enters the danger zone, reducing the risk of accidents.

Safety for pallet load: With Clampers and Pressure Control, Ensuring pallet safety during the inversion process is critical. Adjustable clampers and precise pressure controls secure the load firmly without causing damage to the goods or the pallet. This is especially important for fragile or unevenly distributed loads, providing reliable protection during handling.

By choosing a pallet inverter with these safety features, you can ensure a safer working environment and protect valuable products throughout the process.

Our team will reply in 24 hours

![]() Email: info@fhopepack.com

Email: info@fhopepack.com

![]() Whatsapp: 0086-13951501635

Whatsapp: 0086-13951501635

I'm online now.