Packaging is an indispensable factor for the sales of door panel packaging machines. For buyers, they also hope that their door panels can be packaged more beautifully. For this reason, FHOPE Group provides customers with the following schemes:

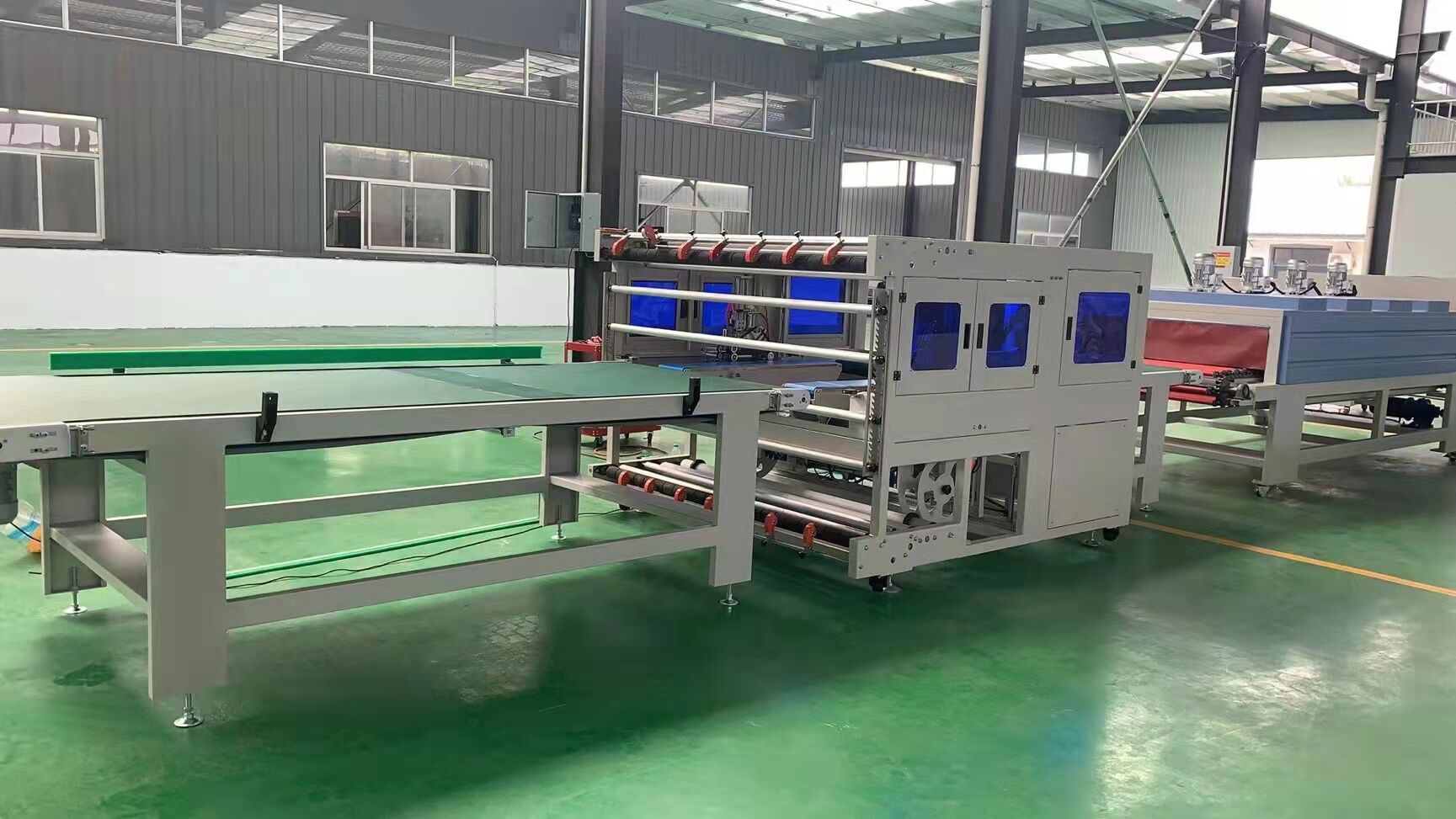

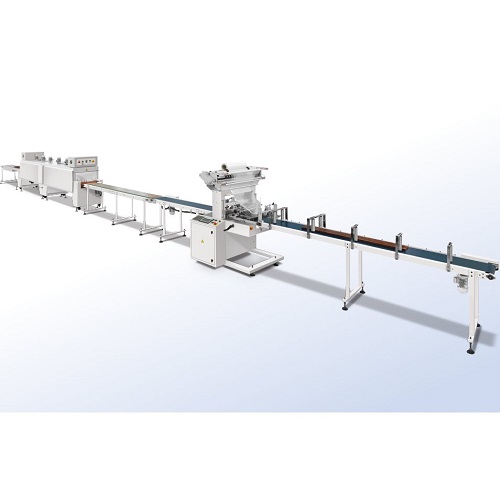

1. Model A: One sealer with two press device

Door Shrink packaging machine is a good way to make this kind of door and panel packaging. Use shrinkable plastic packaging to completely cover the product, and heat shrink the tunnel at constant temperature to make the packaging tight and high tension. There are several materials to choose from, such as PE film, PVC and POF. The recommended thickness is 80-150 microns. For some customers who want thicker and more protective packaging, 200 micron packaging can be provided. Compared with the horizontal stretching packaging machine, this shrinking packaging machine has faster packaging speed, less materials and less restrictions on product size. First of all, our cutter can ensure that the front and back films of customers can be cut off. Secondly, our left and right nip rollers can make the left and right sides of the door packaging more beautiful.

2. Door shrinking machine with three cutters

Different from the first one, with the increase of the number of cutters, the cutters can make the cross section look smoother and less wrinkled than the nip rollers, and the function is the same as above, which is more suitable for stacked door panels and some large goods.

3. Door panel shrinking machine with Motion sealer

This product is upgraded according to the first product, which can provide great convenience for customers. First of all, we have special guard plates in the conveying line to prevent some products with smooth surfaces from shaking during transportation. Workers only need to put the door plate between the two guard plates, without manually adjusting the position of the door plate. At the end of laminating, we will have heat sealing knives on both sides, which can avoid the limitations of the knives and can be adjusted to deal with many different products.

Features:

1. It is a automatic shrinking machine and it can be combined with another line for automatic packaging.

2. PLC&HMI adopted.

3. The solution availableincludes the packing materialn automatic feeding, sealing parts, material recover,shrinking…

4. Full sides shrinking packaging with nice surface.

5. Sensors adopt for inducing the products for fix the position.

6. Two feed-in modes, auto/manual for easily operation,

7. PE film can be choosing with three sides automatically sealing.

8. The different collocations device for different products.

9. Constantly high temperature film heat sealing system for all industrial standard shrink films in the market such as PE. PVC. POF etc.

10. The width of sealing is adjustable for different products.

11. The front feed speed is adjustable according different packaging speed.

12. Hi-speed hot air circulating system inside of shrink tunnel .

13. Sealing system control by sensors, sealing temperature adjusted but PLC.

Parameters:

1.Sealing part

Control: PLC

Structure Material: Carbon steel

Packing Objects:

Length: 1000-4000mm

Width: 1200mm

Height: 180-210mm

Height of Working Table: app. 800mm

Conveyor speed: app. 4-9m/min

Packaging Type: Full packaging

Packing Material: PE/POF/PVC film with reserve pore.

Sealing part power consumption: app.4KW

Power Supply: 380V

Air Supply: 6~8kgf/cm2

2. Shrinking part

Structure Material: Carbon Steel

Length:5000mm

Shrinking tunnel:4000mm

Shrinking Side: W 1400mm x 300mm

Heating Power Consumption: App.20Kw

Calorific: 4PCS

Cooling Fans: 1 Group

Drive Part: Frequency control Motor

Conveyor speed: app. 6m/min

Temperature: 100℃-220℃

Packing Material: PE/POF film with reserve pore.

Power Supply: 380V