Real Leading Manufactuer In steel Wire Coil Packaging Machine

Welcome to our gallery showcasing over 50+ different steel Wire Coil Packaging Machine! Our collection features a wide range of machines designed to meet the diverse needs of various

24/7 Customer Support

There are different ender, coil wrapping machine, pallet inverter, autoamtic coilers per different packaging goal in the safety and efficiency packaging…

Tempore, ultrices morbi accusamus eos quos natus justo totam, quidem.

Tempore, ultrices morbi accusamus eos quos natus justo totam, quidem.

Tempore, ultrices morbi accusamus eos quos natus justo totam, quidem.

FHOPE provding the automation in the coil packaging lie, pallet inveter, upender…helping to improving the packaging efficicey and worker securtity.

There are more machine and packing solution availabe form FHOPE. The blog shows the case or solution with information in detail to help our user better understanding the

possiablity of the packaging and handling

Welcome to our gallery showcasing over 50+ different steel Wire Coil Packaging Machine! Our collection features a wide range of machines designed to meet the diverse needs of various

Welcome to our gallery showcasing over 100+ different Upender & Tilter! Our collection features a wide range of machines designed to meet the diverse needs of various industries. Explore

How to Choose an Injection Mold Flipper? If you’re in the manufacturing industry, then you know the importance of having the right equipment to optimize your operations. One such

more information: http://www.fhopepack.com/PPR%20PVC-pipe-packing-line.html Handling pipes can be a challenging task for industries that deal with them. It requires precision and efficiency to ensure that the pipes are transported and stored

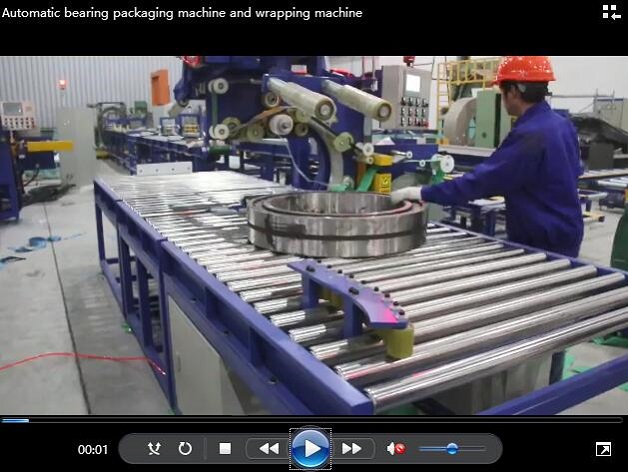

more information: https://www.fhopepack.com/Bearing-packing-machine/ Bearing Packing Machine Solutions A wrapping machine for bearings is a type of packaging equipment used to wrap bearings in protective materials such as plastic film or

Are you tired of the time-consuming and labor-intensive process of handling heavy coils of steel, aluminum, or copper? If so, it’s time to consider investing in a high-quality coil

More information: Automatic hose coil packing machine FPH200 Hose wrapping machine FPH-300 Hose wrapping machineFPH-400 hose wrapping machine FPH-500 hose wrapping machine The Automatic Machine Hose Packing system is designed to

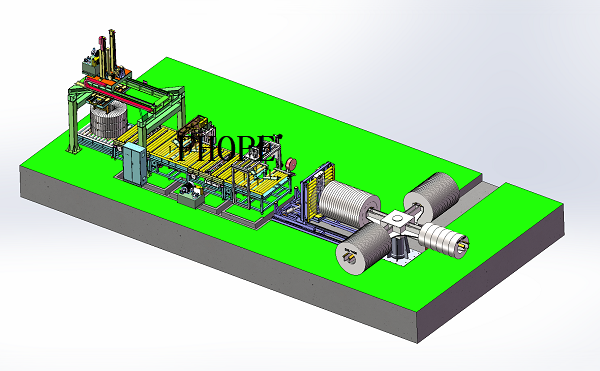

https://www.fhopepack.com/Automatic_Coil_packing_machinery.html A steel coil packaging line helps accelerate the packaging process and minimize the risks associated with handling heavy steel coils. A modern coil packaging line typically includes critical components such as a turnstile, coil wrapping

In Fhopepack, there is able providing a steel mother coil packaging machine for jumbo coil. So many people call it: jumbo coil packing machine, mother coil wrapper, coilmaster

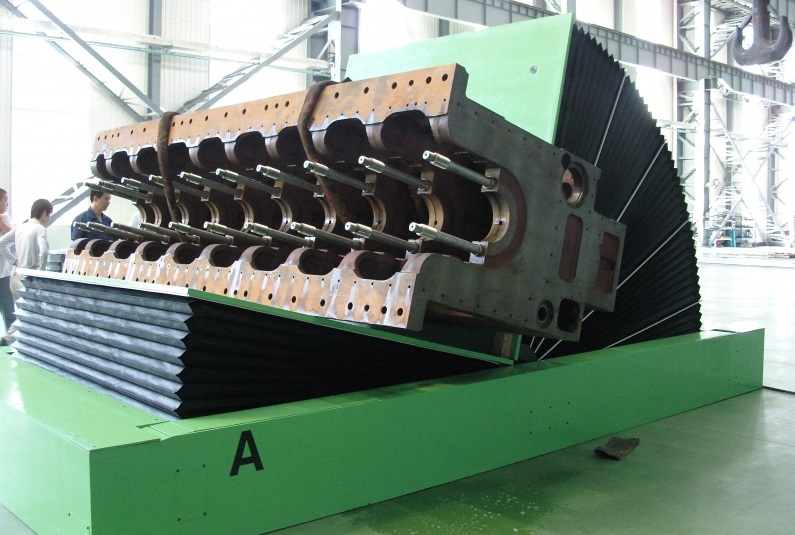

The Steel Coil Tilter is an essential device utilized in the transformer production industry, specifically designed to handle and reposition heavy steel coils used in the manufacturing of transformer

Integrating an automatic aluminum profile film tapping machine into your production process can bring numerous benefits and streamline your operations. This advanced equipment automates the process of applying film

Upgraded Packaging Facility : The upgraded slitting coil service ceter at Mexico now boasts an advanced steel coil packaging line tailored specifically for bundling strip coils post slitting-and-shearing. This

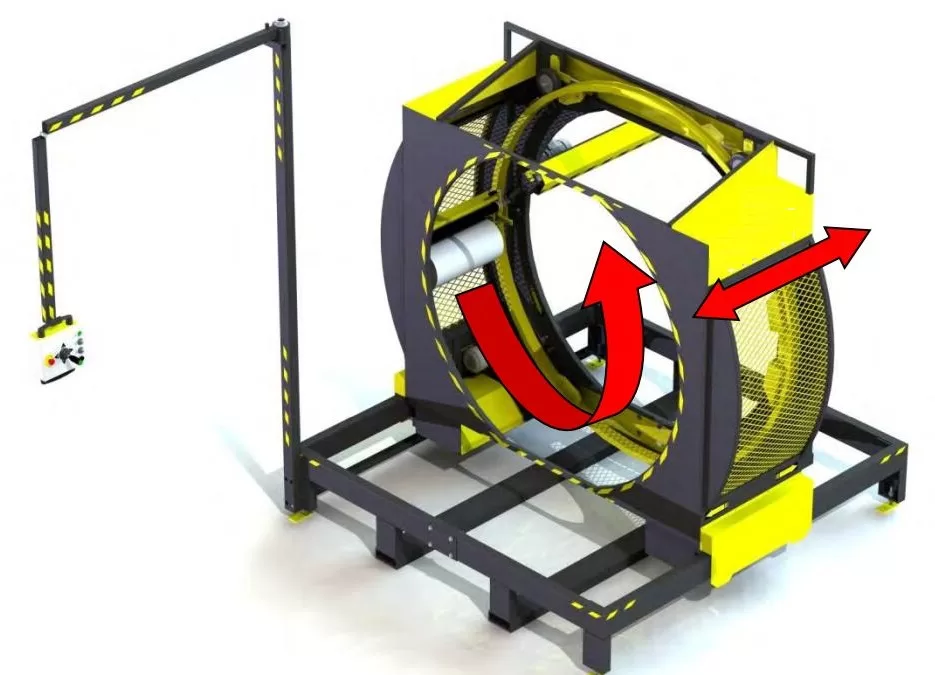

Introduce Introducing the Yellow Jacket Pallet Orbital Wrapper, our user-friendly and efficient machine designed to keep your products safe and secure during transit or storage. With its CE certification,

The High-Speed Side Film Shrink Wrapping Machine is engineered specifically for the packaging of printed materials such as books, filers, notebooks, and magazines. This machine utilizes a side sealing

A shrink packaging machine for notebooks, files, magazines, and similar items is a specialized equipment used for wrapping these products with shrink film to create a tight and protective

The automated steel coil pallet turntable stretch wrap machine is a specialized equipment designed for wrapping steel coils on pallets with stretch film in an automated manner. This machine

The pallet wrapping machine with automatic film cutting is a state-of-the-art equipment designed to streamline the pallet wrapping process and enhance efficiency. This machine offers advanced features and capabilities,