Click to Chat

I'm online now.

|

|

Fhope door packing machine is a series which has been designed by Fhope’s best engineers and designers. This series is for modern door industry and it utilizes in achieving special packaging goals for manufacturers in door industry. The machine makes perfect package to prevent the products from abrasion, friction, scratch,dust and water during storage and transportation. Easy operation and high efficiency are the main factors to the machine’s popularity. Our reasonable price also made the machine become an accessable solution for the customers.

Our rich experience helps us to have the opportunity of covering many scales of industrial products companies. We will try our best efforts to assist with your projects.

■ Flooring industries (parquet, laminate, cork, and solid wood).

■ Moulding industries (panels, strips, and solid wood).

■ Kitchen and bathroom industries.

■ Furniture (knockdown).

■ Board industries (bench, ceiling, wall boards).

■ Door and window industries.

How to packing machine door by machine and what is the possible solution to reduce the door packing procession, following is the main ways:

Economic Type Door Shrink Packing Machine: A Cost-Effective Packaging Solution The economic type door shrink packing machine offers a highly efficient solution fo...

Door Horizontal Orbital Wrapping Machine: A Comprehensive Packaging Solution The Door Horizontal Orbital Wrapping Machine is a versatile and efficient packaging s...

Door Shrinking Machine with Motion Sealer: Advanced Packaging Technology for the Modern Manufacturer The Door Shrinking Machine with Motion Sealer is an advanced ...

This semi-automatic door wrapping machine offers high performance. Wrapping layers are fully adjustable, supporting bottom, middle, and top wrapping for enhanced ...

The Door Stretch Wrapping System offers comprehensive horizontal sealing and shrink-wrapping for large items such as doors and sheets. Equipped with an optional s...

This machine is a versatile sealing and shrinking system designed for fully enclosed packaging of doors and sheets. With one cross-sealer and two motion sealers, ...

A door packing machine streamlines the packaging process for doors by ensuring safe, efficient, and secure wrapping. It reduces manual labor, increases productivi...

A door packing machine streamlines the packaging process by securely wrapping doors with protective materials. Designed to enhance efficiency and minimize manual ...

A door packing machine is an efficient solution for packaging doors of various materials, including wood, metal, and PVC. Designed for durability and precision, i...

The automated door packing machine offers a seamless solution for efficiently packaging doors. Designed to optimize speed and accuracy, it ensures products are se...

Designed for protective packaging of wooden doors, metal doors, and flat panels, these machines wrap products with high-quality bubble film to safeguard against s...

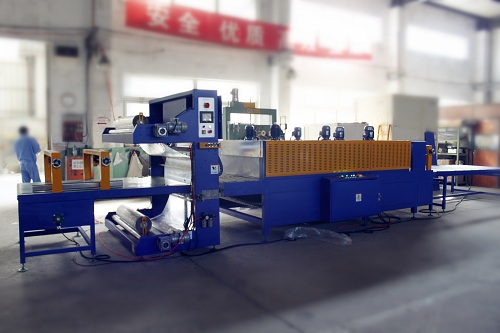

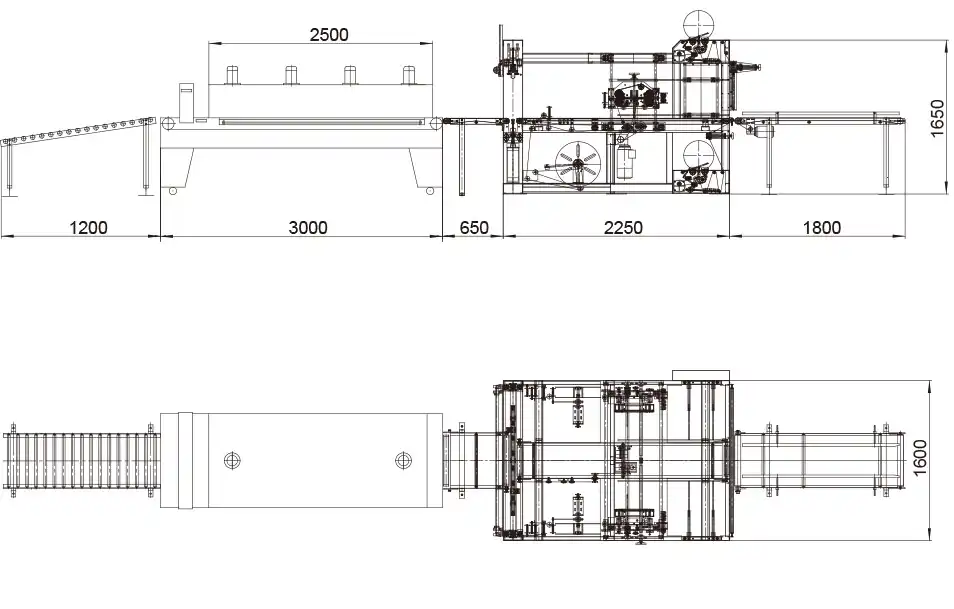

Door shrinking machine is consisted of conveyors, panel bagging machine and shrink tunnel. Easy to accomdate different products, providing a better protection and having a better appearance. After passing through the film covering machine, the door will be covered with film and moving into the shrinking tunnel. By heating, the film will be shrink wrap on the surface of the door which is smooth and nice for the door package

This is the solution with one sealer + two press device for door sealed pcking. The door panel first will be covered with plastic film and after that the heat blade will cut and seal the edges of the package. The bagged panel then will be sent into the hot tunnel for shrinking. The package will be very tight and neat after shrinking process.

After feeding the door into infeeding conveyor, the door will be covered by film applicator, And than the door passing throught the shriking tunnel for shrink heating. After door come out the shrinking tunnel, the door both sides will be pressed by two vertical press rolls. That is used to press the two sides of the panel after shrinking and make a tidy edge.

This advanced packaging machine features three efficient sealers that simultaneously seal three sides of each package, significantly speeding up the process and securely encasing products. After sealing, the package enters a shrinking tunnel where it conforms closely to the product, further reducing packaging time.

The fully sealed package provides superior protection against dust, moisture, and transport damage, making it ideal for sensitive items. This sealing technology enhances product safety and longevity while improving packaging efficiency, ensuring products reach consumers in optimal condition.

The motion sealer door shrink packing macine includes one cross sealer with two motion sealers for sealed door bag packing which adds the shrinking tunnel and horizontal conveyor for efficiency door packing.Our tean offer the equipments with international advanced and reliable high-speed edge sealing technology.

How to get a perfect door packaging withoug wrinkle all sides? The three sealers door shrinking solution is a good choice. The door will be infeeing into the film sealing station so that all side of the film will be cutt and sealed nicely by three sealers with proper size bag. And after shrinking procession, the door will be nice packing by regular, smooth shink at the surface.

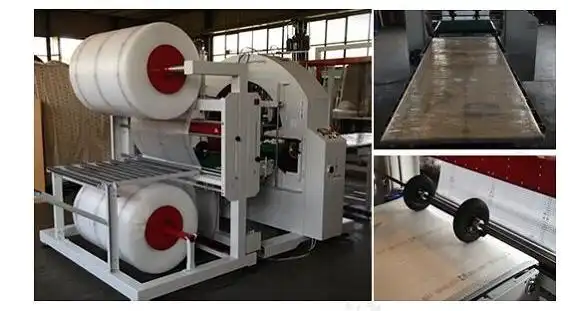

Door horizontal wrapping machine is designed for packaging the product through stretch wrapping. Stretch film will be used as the packaging material to wrap the door panel and the machine is controlled by the control system. The setting is changeable and can be operated by users themselves. Different packaging methods such as overlap rate control, over wrapping on front and rare parts, bubble film covering are achivevable as well. Below are specification of the different machines.

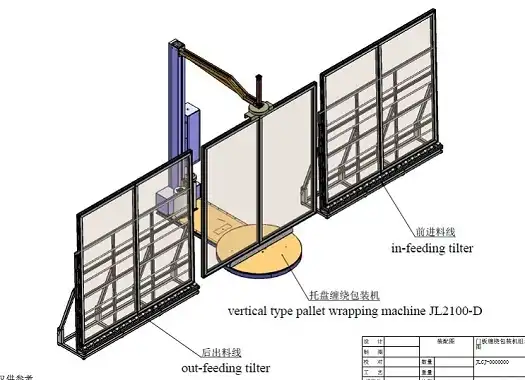

The Fhope Pack packaging solution integrates an in-feeding conveyor, a sophisticated wrapping machine, and an out-feed conveyor, expertly designed to accommodate doors of various sizes, weights, and lengths. This system ensures that each door is securely wrapped, protecting it from environmental factors and transportation damage. The adjustable settings on the wrapping machine allow for a customized fit for each product, ensuring efficient and tight packaging.

As doors move through the system from the in-feeding conveyor through the wrapping phase, and finally to the out-feed conveyor, the transition is seamless and efficient. This design minimizes the potential for damage while maximizing productivity, making the Fhope Pack solution ideal for door manufacturers and distributors seeking a reliable and adaptable packaging process.

The comprehensive packaging solution includes a film covering machine, a wrapping machine, and an out-feeding conveyor, designed to fully protect doors during transit. This system uses PE and bubble films applied by the film covering machine to create a barrier against environmental and physical damage. The films are cut and sealed to match each door's dimensions, ensuring enhanced integrity.

Once the films are applied, the doors move to the wrapping machine where they are wrapped in additional protective material using a stretch wrapping technique that immobilizes the doors, ensuring they stay secure during distribution. The out-feeding conveyor then moves the packaged doors smoothly to their next destination. This efficient packaging solution is ideal for manufacturers and distributors seeking to reliably protect their products.

Our economic door packaging solution combines a film covering machine with a top pressing down device to efficiently encase doors in protective film. This system utilizes a turntable with a film applicator, ensuring thorough and uniform coverage. The innovative turntable design allows for the door to be rotated during the wrapping process, guaranteeing that every part of the door is tightly wrapped and fully protected against external elements.

The inclusion of a top pressing down device in this solution is key, as it stabilizes the door, preventing any movement that could disrupt the film application. This feature ensures that the stretch film is applied smoothly and consistently, providing superior protection. Ideal for businesses seeking a cost-effective yet robust packaging method, this solution minimizes waste and optimizes material use, ensuring that doors are securely packaged and remain in pristine condition during transportation and storage.

We've compiled key FAQs about coil packing line projects for your convenience. If you don't find your question, call us at +8613951501635 or email info@fhopepack.com.

An automatic door packing machine is specialized equipment used to wrap and protect doors during packaging and transportation. It automates the process, applying materials like stretch film or PE film to ensure the door remains secure and free from damage during handling. This machine helps streamline the door packaging process, improving productivity, and ensuring consistent, high-quality wrapping for doors of various sizes and materials.

A manual door packing machine requires an operator to control each step of the packing process. While it still utilizes some level of automation in wrapping or sealing, the manual machine demands a higher degree of human intervention. Common features of a manual door packing machine include semi-automated wrapping systems, manual adjustment controls, and the ability to switch between various packaging materials.

Typically, manual door packing machines are favored by smaller businesses or operations with limited packaging needs, as they offer a cost-effective solution without a significant upfront investment in automation.

Manual door packing machines offer several key advantages:

Cost-Effective for Small-Scale Production: With lower initial costs than their automatic counterparts, manual machines are ideal for small and medium-sized enterprises (SMEs) or businesses just starting out. They provide essential packaging functions without the need for a large capital outlay.

Greater Flexibility: Manual packing allows operators to make adjustments and handle custom packaging needs more easily. This adaptability makes manual machines a preferred choice for businesses with diverse product ranges or those that frequently adjust their packaging styles.

Lower Maintenance Costs: Since these machines do not rely heavily on advanced technology, their maintenance requirements tend to be simpler and less costly. They generally have fewer mechanical components, which translates into reduced repair and downtime expenses.

While manual door packing machines can be cost-effective and flexible, they come with notable downsides:

Labor-Intensive: The need for constant operator involvement can be a drawback, especially when scaling up production. This labor requirement can lead to fatigue and limit the production capacity.

Inconsistent Quality: Unlike automated systems that standardize packaging processes, manual machines depend on the operator's skill, leading to potential inconsistencies. Variability in the quality of packaging can affect product presentation and even durability.

Increased Risk of Human Error: Manual operations are more prone to mistakes, which can impact quality and increase the likelihood of packaging flaws. Repeated errors may lead to product returns and ultimately impact the company’s reputation.

Automatic door packing machines, as the name suggests, use automation to handle the majority of the packaging process, from wrapping and sealing to labeling. These machines are engineered with advanced technologies, including sensors, conveyors, and programmable logic controllers (PLCs) that enable precise and consistent operations. Automatic machines are typically employed by large-scale manufacturers who require high-speed, high-volume packaging with minimal manual intervention.

Automatic door packing machines come with several powerful advantages:

Speed and High Productivity: One of the main appeals of an automatic machine is its ability to handle large volumes at high speeds. This efficiency boosts production output, making it suitable for manufacturers with demanding schedules or high customer demand.

Consistent Quality Control: Automation minimizes the impact of human error, ensuring uniform packaging quality across each product. This is essential for brands that prioritize consistent, high-quality packaging as part of their reputation.

Reduced Manual Labor and Improved Safety: With less need for human intervention, automatic machines help minimize labor costs and reduce the risk of accidents associated with repetitive tasks. Enhanced safety features, such as automated shutdowns and sensors, further reduce potential hazards for operators.

Although automatic door packing machines excel in high-output environments, they do come with some drawbacks:

Higher Initial Investment: The advanced technology in automated machines comes with a significant initial price. For businesses operating on a limited budget, this cost may be a barrier.

Complex Maintenance Requirements: Due to their sophisticated technology, automatic machines require skilled technicians for maintenance, increasing the costs and risk of downtime.

Less Flexibility for Small-Scale Production: Automatic machines are designed for high-volume, standardized packaging, which may not be suitable for businesses requiring frequent adjustments or custom packaging options.

When deciding between automatic and manual door packing machines, businesses should consider the following factors:

Cost: While manual machines are more affordable upfront, automatic machines tend to yield a better return on investment (ROI) for high-output needs due to their speed and efficiency.

Speed and Productivity: Automatic machines lead in productivity, making them ideal for large-scale operations, whereas manual machines may struggle to meet the same output levels.

Quality and Consistency: Automatic machines ensure standardized quality, while manual machines may produce variable results due to operator dependency.

The cost of door packing machines can vary widely depending on factors such as the level of automation, production capacity, brand, and additional features. Here’s a breakdown of typical price ranges:

When choosing an automatic door packing machine, selecting a model with the right features is essential to maximize efficiency, quality, and ease of use. Here are the top features to consider:

Automation Level and Control System

Material Compatibility

Adjustable Packing Size and Flexibility

Speed and Efficiency

Precision and Quality Control

Safety Features

Energy Efficiency

Durability and Build Quality

Integrated Labeling and Printing

Internet of Things (IoT) and Connectivity

Modularity and Customization Options

Ease of Maintenance

FHOPE, a well-known manufacturer of packaging solutions, provides comprehensive support for the installation, maintenance, and ongoing operation of its door shrink-wrapping machines. Here's an overview of the main types of support offered by FHOPE:

Installation Support

On-Site Installation Services: FHOPE offers on-site installation services with trained technicians who ensure the shrink-wrapping machine is set up correctly and configured according to your specific operational needs. This includes assembling the machine, connecting it to power sources, and testing all functions to ensure optimal performance.

Detailed Installation Guides and Documentation: If on-site installation isn’t feasible, FHOPE provides detailed installation manuals and video tutorials. These resources walk customers through each step of the installation process, ensuring that even remote teams can handle setup with minimal confusion.

Remote Installation Assistance: For companies that prefer remote guidance, FHOPE offers support via video calls, phone consultations, or chat assistance. A technician can walk operators through the setup and answer any questions in real time.

Training and Operation Support

Comprehensive Training Programs: FHOPE offers on-site or remote training sessions to ensure your team knows how to operate the shrink-wrapping machine safely and efficiently. Training covers everything from basic operations and troubleshooting to advanced machine settings and quality control practices.

User Manuals and Video Tutorials: To assist operators in learning how to use the machine, FHOPE provides user manuals, videos, and quick-start guides. These resources allow teams to refer back to specific instructions as needed, which can be helpful for new hires or refresher training.

Ongoing Technical Support: FHOPE’s support team remains available for questions even after the initial setup and training. This ensures operators can get real-time answers to operational questions or guidance for handling new packaging requirements.

Preventive Maintenance Programs

Scheduled Maintenance Plans: FHOPE offers preventive maintenance plans designed to maximize machine uptime and prevent unexpected breakdowns. These plans often include routine inspections, adjustments, and replacements of parts subject to wear and tear.

Maintenance Checklists: For companies handling maintenance internally, FHOPE provides checklists that outline regular maintenance tasks, such as cleaning, lubrication, and calibration. These checklists help operators stay consistent with maintenance schedules and keep the machine in top working condition.

Replacement Parts Supply: FHOPE maintains a stock of commonly needed replacement parts and can quickly ship them to minimize downtime. They also provide a parts catalog and recommendations on which parts to keep on hand for rapid response to potential issues.

Technical Support for Troubleshooting

Remote Diagnostics Support: FHOPE’s technicians can assist with diagnosing issues remotely, helping operators identify and resolve problems as quickly as possible. For IoT-enabled machines, FHOPE can sometimes remotely access the machine’s diagnostics data to pinpoint issues without requiring a physical inspection.

Hotline and Chat Support: FHOPE offers phone and online chat support with technical experts who can walk operators through common troubleshooting processes, reducing downtime caused by minor issues.

On-Site Technician Dispatch: For more complex issues, FHOPE can dispatch technicians to your location for in-depth diagnostics and repairs. This ensures that significant problems are addressed by professionals who are highly familiar with the machine.

Warranty and Extended Support Options

Comprehensive Warranty: Most FHOPE door shrink-wrapping machines come with a standard warranty covering parts and labor for a specified period, protecting your investment against manufacturing defects or early component failure.

Extended Warranty and Service Contracts: For added peace of mind, FHOPE offers extended warranty options and service contracts that cover a broader range of services or a longer duration. This is beneficial for companies looking to secure predictable support costs and minimize risk over the machine’s lifespan.

Upgrades and Optimization Support

Software and Firmware Updates: For machines with programmable logic controllers (PLCs) or IoT capabilities, FHOPE offers software and firmware updates to improve functionality or add new features. Keeping the machine up-to-date can enhance performance and extend its usable life.

Custom Optimization Services: FHOPE can also help modify machine settings or configurations to match new packaging requirements, providing optimization services to align the machine’s operation with evolving production needs.

Resource Library and Knowledge Base Access

Online Knowledge Base: FHOPE provides access to a resource library filled with manuals, troubleshooting guides, and best practice documents. This self-service option is valuable for operators looking to resolve minor issues or better understand the machine’s functions without needing to contact support.

Video Tutorials and Training Modules: In addition to written resources, FHOPE maintains a collection of video tutorials and training modules that cover various aspects of machine operation, maintenance, and troubleshooting.

Our team will reply in 24 hours

![]() Email: info@fhopepack.com

Email: info@fhopepack.com

![]() Whatsapp: 0086-13951501635

Whatsapp: 0086-13951501635

I'm online now.