Click to Chat

I'm online now.

Fhopepack Innovation

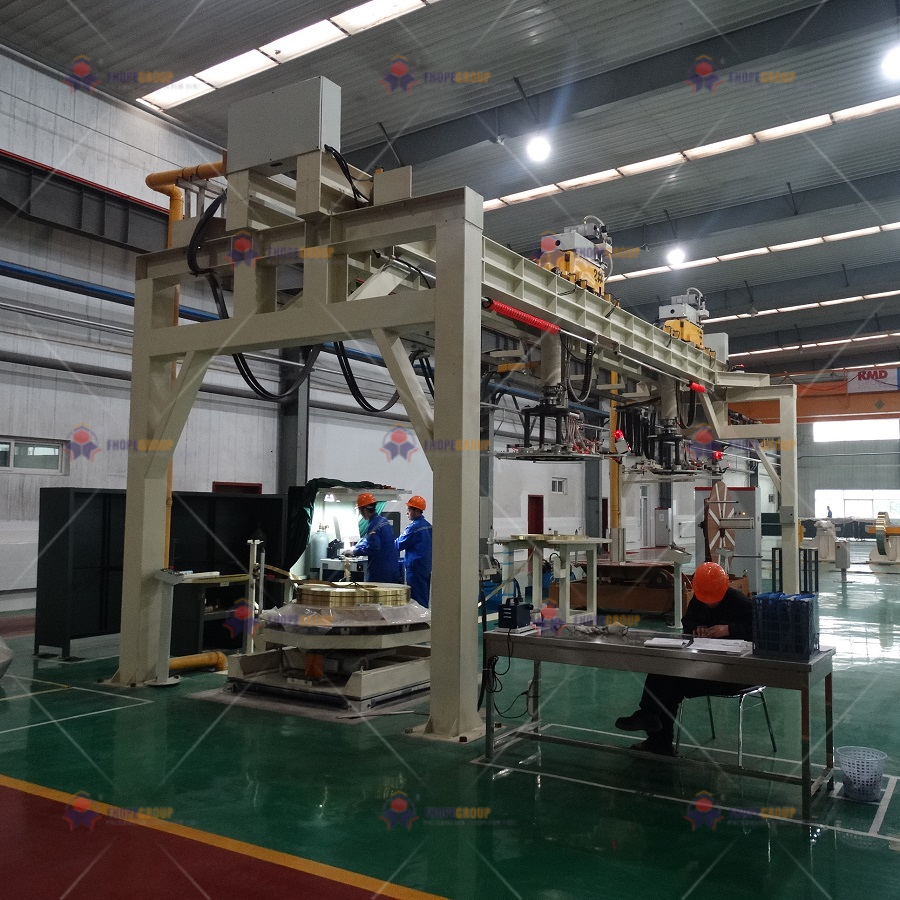

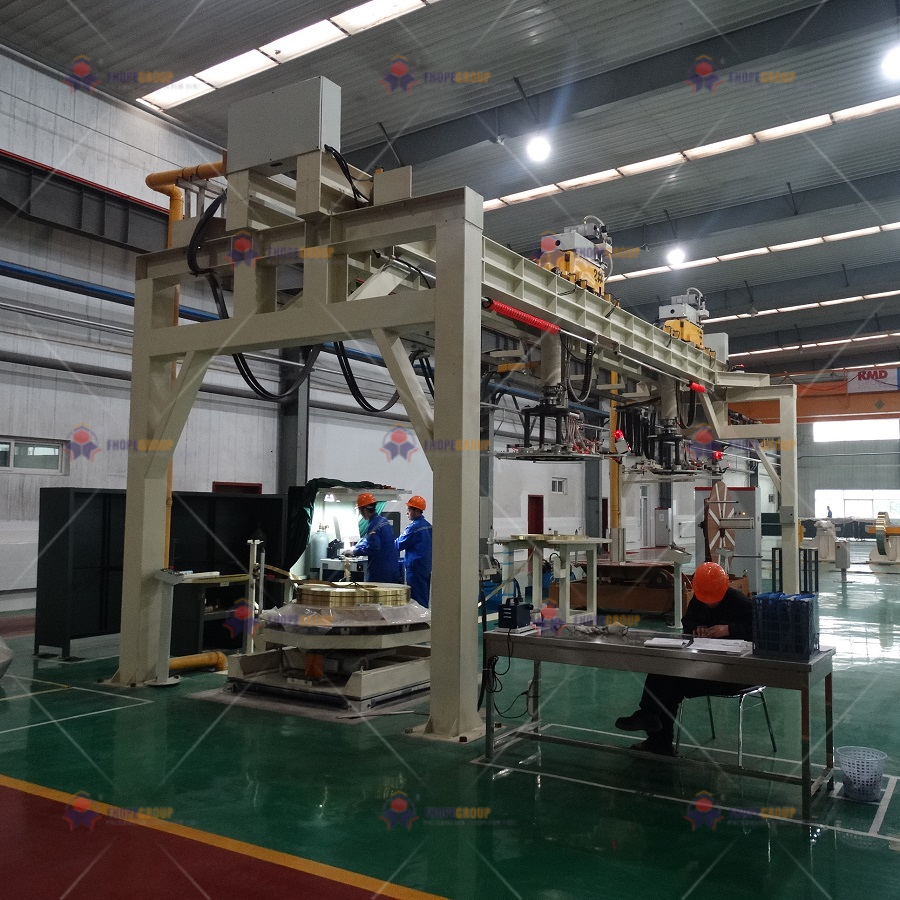

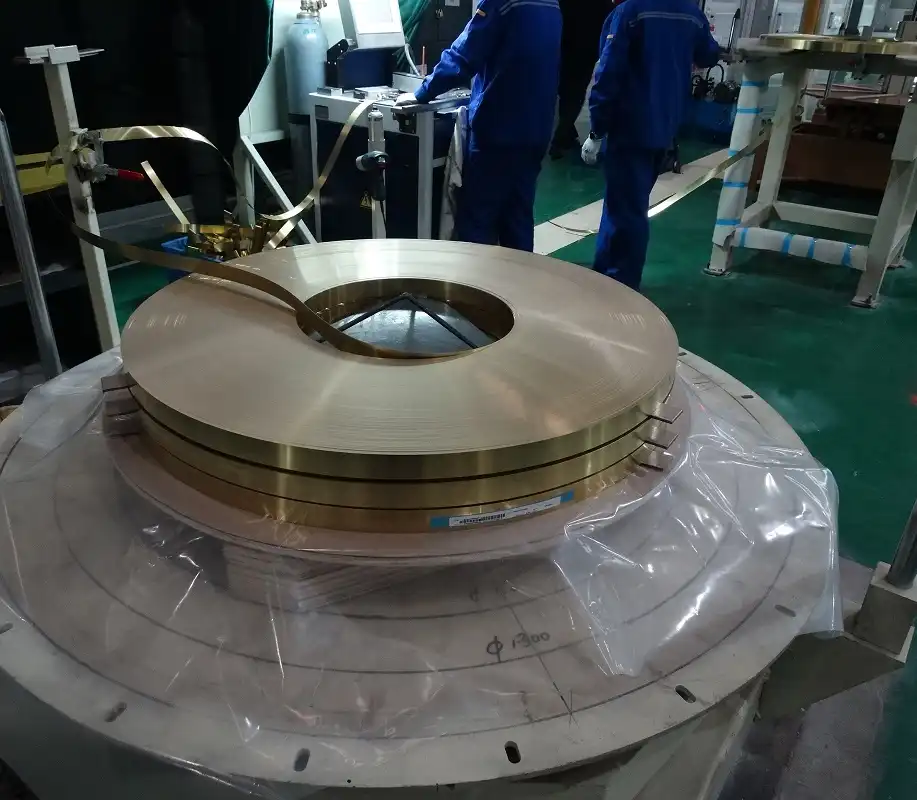

Welding lines are industrial equipment used to efficiently and consistently weld multiple copper coils together. This process minimizes manual handling and ensures high-quality welding. The exterior joint of the coil is welded on a rotating platform, while the interior joint is welded on a transit platform. A vacuum chuck is used to position the coil precisely and stably during the welding operati

Multi-coil Welding lines are typically industrial equipment that are designed for multi-coil of welding together, as be a good choice for efficiently and consistently welding the copper coils. The welding line has the operation process, including:

The welding operation will ensure efficient and high-quality welding of the copper coils, and to minimize the need for manual handling of the coils. In the welding operation, the exterior joint of the coil is welded in the rotate-lifter platform and the interior joint is welded in the transit platform. The vacuum chuck will carry the coil between the different stages of the welding operation can be a useful way to ensure precise and stable positioning of the coil during welding.

Main features of the welding line

The relentless demand for copper components in electronics, automotive, and HVAC systems has exposed a critical bottleneck in manufacturing: the disruptive handoff between copper coils. As production speeds increase and labor costs soar, facilities processing copper strip face mounting pressure to eliminate downtime between coil changes while ensuring perfect material continuity for high-tolerance processes like electroplating and precision stamping.

Coil-to-coil transitions remain manufacturing's silent productivity killer. According to industry studies, coil changeovers consume 15-30 minutes per transition in manual operations, creating compounding losses:

Costly Production Breaks: "We struggle with 20+ minutes of dead time every changeover," reports a stamping plant supervisor. "Our 1,200-ton presses sit idle while technicians scramble to thread new material." This translates to 5-8% annual capacity loss for high-volume facilities.

Material Waste & Quality Issues: End-users confirm: "Our biggest frustration is inconsistent welds causing strip breaks in plating tanks." Each manual splice wastes 1.2-2 meters of copper strip, while weak joints lead to downstream defects. One connector manufacturer reported 12% rejection rates at weld points during audits.

Safety & Labor Intensiveness: Handling 3-5 ton copper coils poses critical risks. A safety manager at a transformer plant admits: "We've had three near-misses this year during coil changes. Manual stacking also causes back injuries and pallet instability during shipping."

Throughput Limitations: "Automated presses starve during changeovers," laments an automotive parts producer. "We can't leverage our 1,500-strokes/minute capability when coils change every 90 minutes."

The next-generation copper processing line integrates laser welding precision with robotic material handling to create uninterrupted production flow. This turnkey system directly attacks the core challenges:

Core Technical Specifications:

Operational Workflow:

Innovative Features:

| Performance Metric | Traditional Manual Process | Automated Welding & Stacking | Improvement |

|---|---|---|---|

| Changeover Time | 15-30 minutes | < 30 seconds | 97% reduction |

| Material Waste | 1.5-2 meters/changeover | 0.2 meters/changeover | 87% reduction |

| Labor Requirements | 2-3 operators/shift | 0.5 operators (monitoring) | 75% reduction |

| Damage Incidence | 3-5% of coils | <0.5% of coils | 90% reduction |

| Max Line Speed | Limited by changeovers | Uninterrupted 24/7 operation | 15-20% throughput increase |

| ROI Payback Period | N/A (baseline) | 8-14 months | [Industry average] |

Ningbo Jintian Copper, Production Director reports:

"Before implementation, we lost 22 minutes per coil change with 3% material waste. After installing the automated welding and stacking line, we've achieved near-zero transition downtime and reduced scrap by 86%. The system paid for itself in 11 months through labor savings and increased press utilization alone."

The era of production interruptions from copper coil changes is ending. Integrated welding-stacking systems represent more than incremental improvement—they enable truly continuous manufacturing essential for electrification component production. As copper demand surges 300% by 2040 (IEA projections) , these automated solutions will become competitive necessities. Next-generation developments include AI-driven weld quality prediction and fully autonomous material handling fleets. For facilities targeting zero-changeover production, the path forward is clear: audit your current coil transition process and calculate your hidden downtime costs. The automation payoff isn't just possible—it's measurable from day one.

I'm online now.