Click to Chat

I'm online now.

When choosing an orbital wrapping machine, consider both your product requirements and the machine's performance. Ensure the machine is compatible with your product dimensions and shapes, especially for long or irregular items like pipes or profiles. Choose between semi-automatic or fully automatic models based on your production needs. Key factors include durability, ease of operation, and customization options—essential for handling diverse products. Additionally, ensure the machine supports your preferred packaging materials. Lastly, select a reliable supplier with industry expertise, strong after-sales support, and cost-effective solutions to ensure long-term efficiency and reliable operation.

Fhopepackaging machines have the highest production speed and lowest operating costs. Machine shape: Application: Following are some applications per clients pack...

Fhope packaging machines are designed to have the highest production speed and lowest operating costs, making them an ideal solution for businesses looking to str...

Fhope specializes in providing automatic packaging machines and balers for the waste industry, including RDF, SRF, MSW, and recyclable materials. With over 20 yea...

Fhope machinery range includes models specifically designed for packaging cement fiberboard and other industrial products. Our China-based horizontal wrapping mac...

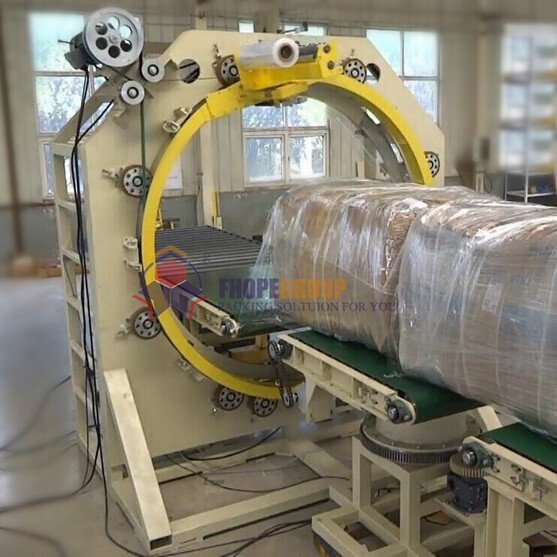

Automatic Orbital Wrapping Machine is designed for ease of operation, making it an ideal solution for businesses looking to streamline their packaging processes. ...

Fhopepackaging machines have the highest production speed and lowest operating costs. Machine shape: Application: Following are some applications per clients pack...

Horizontal, orbital stretch wrappers provide fast and secure wrapping of long products, regardless of their shape, even if not well-defined. Our plastic horizonta...

Orbital shrink wrapper uses a speed control inverter and foot pedal to wrap the film around the product for the required time. Once the package is wrapped, the sh...

Automatic wrapper is designed for horizontal wrapping with stretch film, providing final bubble wrap protection for your products. Our orbital wrappers come with ...

The price of an **orbital stretch wrapper** varies based on features, automation level, and customization. Fhopepack offers cost-effective solutions for securing ...

Horizontal orbital stretch wrapper is designed for pallet packing, providing both 4-sided and 6-sided packaging capabilities. The equipment is programmed to contr...

Our portable and innovative orbital stretch wrapper is designed to offer the same wrapping capabilities as traditional turntables, but with added convenience and ...

Stretch Wrapping machine is designed for easy installation, and requires only one person for setup. The machine features a chain-driven film carriage, a foldable ...

Our environmentally-friendly polyethylene film is designed to be recycled or used for energy recovery, making it a sustainable packaging solution. Our horizontal ...

Our packaging machine features adjustable top and bottom packaging capabilities, with an automatic sensor that detects the height of the tray. The machine is desi...

Fhopepackaging machines have the highest production speed and lowest operating costs. Machine shape: Application: Following are some applications per clients pack...

Our horizontal stretch wrapping machine is a cutting-edge packaging solution designed specifically for producing brass, steel profiles, aluminum, glass, stainless...

Our horizontal shrink wrapping machine offers a range of processes, including welding, embossing, printing, cutting, sealing, and clamping, commonly used on produ...

Our used horizontal stretch wrapping machines are structurally similar to the semi-automatic series, featuring motorized belt conveyors or rollers, photoelectric ...

Our Yellow Jacket Orbital Stretch Wrappers, available in the semi-automatic series, are equipped with motorized belt conveyors or rollers, photocell product surve...

Our Yellow Jacket Pallet Wrappers meet the challenge of balancing high productivity with the need for flexibility across a diverse range of products. These opposi...

We have a horizontal wrapping machine featuring feed and discharge roller conveyors ideal for particularly long packaged goods, across galvanized or PVC coated fr...

Our automatic packaging machine and baler are designed for the waste industry, including RDF, SRF, MSW, and recyclable materials. As a part of Fhope, we offer inn...

Our Fhope packaging machines offer the highest production speed and lowest operating costs in the industry, making them a top choice for our clients. We offer cus...

Bale wrappers are essential machines used in agriculture to wrap baled hay, straw, and other materials with plastic film. They protect these materials from the ef...

Our bubble film wrapping machine is expertly designed for heating plates, with a special design tailored to meet our customers' unique packaging requirements. As ...

Our orbital stretch wrapper with superior tension packaging is expertly designed to wrap pallets or large items with bubble film. The machine rotates the item aro...

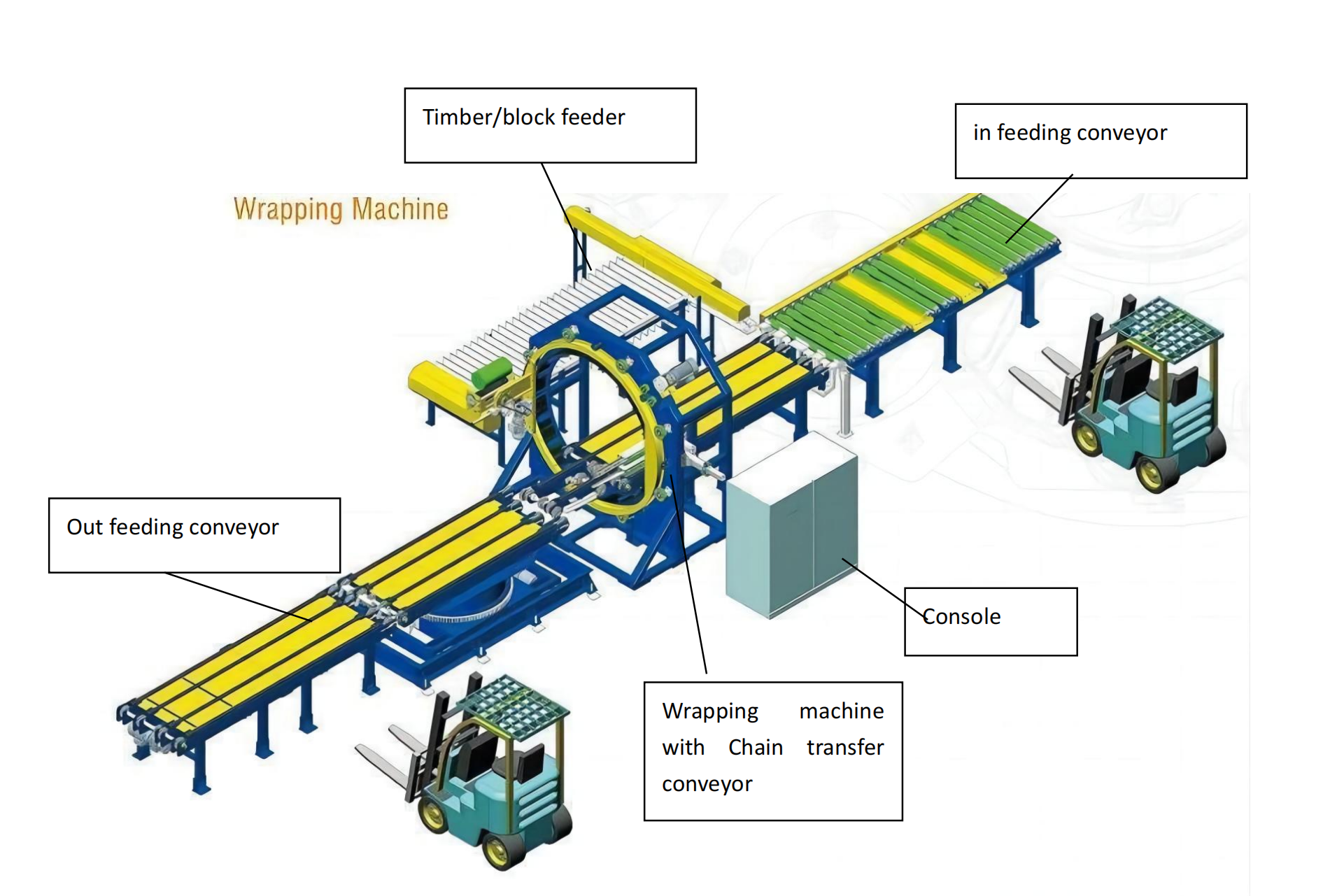

Our E500 Horizontal Orbital Wrapper Machine is designed for wrapping wood packaging materials, such as stretch film and paper, to protect them during storage and ...

Our orbital stretch wrapper with PVC belt conveyor is an effective machine for wrapping pallets or large items with stretch film. The wrapper rotates the item bei...

Our spiral orbital wrapper is specifically designed for wrapping bubble film. With its unique spiral design, this wrapper offers efficient and reliable wrapping f...

Our orbital stretch wrapper is specifically designed for packages with a minimum length of 400mm. For small and short packages, the wrapper faces two main challen...

This article evaluates different horizontal wrapping systems, comparing their features and performance to help businesses find the best solution for their packagi...

Implementation and Delivery: Effective Setup of a Horizontal Orbital Wrapping System Implementing a horizontal orbital wrapping system is a significant step towar...

Manufacturers face various packaging challenges, such as handling large or awkwardly shaped products, ensuring stability during transport, and maintaining efficie...

This analysis delves into the essential aspects of selecting the ideal orbital packaging machine for various applications. It highlights important considerations ...

Horizontal rotary wrapping machines offer versatile packaging solutions for various industries, enhancing efficiency and ensuring product protection. By comparing...

Choosing a horizontal pallet wrapping machine requires assessing key factors such as wrapping speed, machine reliability, and compatibility with various pallet si...

How to Assess the Automation Levels in Six-Sided Horizontal Orbital Stretch Wrappers for Board Bundles As industries strive to improve operational efficiency and ...

Evaluating the ROI of Upgrading Your Six-Sided Horizontal Orbital Stretch Wrapper for Board Package In the fast-paced world of manufacturing and logistics, effici...

Learn effective negotiation tactics to secure the best ring wrapping machine for bulk packaging. This guide offers strategies to help you assess supplier offers, ...

This guide outlines essential steps for implementing a spiral stretch wrapper to improve product handling efficiency. It covers the installation process, staff tr...

This guide outlines the demand identification process for implementing a rotational stretch wrapping machine for high-speed packaging. It discusses important cons...

The Horizontal Cargo Wrapping Machine plays a crucial role in enhancing packaging processes across industries. This market analysis delves into the rising adoptio...

The Horizontal Bundling Machine plays a key role in protecting products during shipping and storage. This comparison of available solutions highlights factors lik...

This guide provides insights into selecting the ideal ring orbital wrapping machine for cost optimization. It highlights essential aspects like machine performanc...

The Internal Decision Guide for Choosing a Horizontal Shrink Wrap Machine provides businesses with a comprehensive overview of essential considerations like perfo...

Negotiation strategies for a Horizontal Ring Wrapper for Bulk Material Packaging aim to secure the best value by focusing on pricing, maintenance packages, and af...

Discover our high-quality Orbital Wrapper for Sale, designed to boost your packaging efficiency. Ideal for wrapping long and irregular-shaped products, this machi...

An orbital wrapper is a packaging machine used to securely wrap products by rotating them horizontally, applying stretch film or other materials. It is ideal for ...

A Horizontal Stretch Wrapper is a machine designed to wrap products using stretch film in a horizontal orientation. It is perfect for packaging long or uniquely s...

The Orbital Stretch Wrapper is a highly efficient packaging solution, ideal for securing and stabilizing products of varying shapes and sizes. It uses stretch fil...

The horizontal stretch wrapping machine is ideal for wrapping elongated items such as profiles, pipes, and boards. It securely wraps products using stretch film, ...

Why Customization Matters in Orbital Wrapping Machine: Our Approach In today's fast-paced industrial environment, achieving efficiency and reliability in packagin...

The Orbital Stretch Wrap Machine offers an efficient way to wrap elongated or uniquely shaped products. Utilizing horizontal film application, it ensures tight, u...

The Orbital Stretch Wrap Machine offers fast and reliable wrapping for products of various shapes and sizes. It enhances packaging efficiency by using stretch fil...

The orbital pallet wrapper is an advanced packaging machine designed for efficiently wrapping pallets with stretch film. It secures products tightly, ensuring sta...

The horizontal pallet wrapping machine automates the process of wrapping pallets with stretch film, providing consistent and secure packaging. It enhances product...

The Yellow Jacket Orbital Stretch Wrapper offers a reliable way to secure large or oddly shaped items with minimal effort. Its orbital wrapping mechanism ensures ...

The Orbital Pallet Wrapping Machine is designed to securely wrap pallets with efficiency and precision, improving packaging speed and stability. Ideal for busines...

The orbital wrapping machine wraps products in a consistent, circular motion, providing secure and protective packaging. It's perfect for items like pipes, panels...

The Orbital Shrink Wrap Machine is designed for efficient and secure packaging, wrapping products in a tight, protective film. Ideal for industries such as logist...

This used orbital stretch wrapper provides a cost-effective way to streamline your packaging process. Designed to wrap products quickly and securely, it helps red...

The Horizontal Pallet Wrapper is an efficient packaging solution that wraps pallets horizontally with stretch film, ensuring load stability and protection during ...

The Yellow Jacket Orbital Stretch Wrapper is a reliable packaging machine designed for securing irregularly shaped and oversized loads. Ideal for industries requi...

Lantech Orbital Stretch Wrapper is engineered for efficiency and precision in packaging. This advanced machine wraps products uniformly, providing optimal load st...

The Orbital Stretch Wrapper offers superior wrapping capabilities for elongated and bulky items. This automated machine rapidly encircles products with stretch fi...

The Used Orbital Stretch Wrapper provides cost-effective solutions for securing and protecting elongated products during shipping or storage. This pre-owned machi...

The Used Orbital Stretch Wrapper provides cost-effective solutions for securing and protecting elongated products during shipping or storage. This pre-owned machi...

The Used Orbital Wrapping Machine is an excellent investment for industries requiring effective and reliable packaging of large, elongated products. This pre-owne...

The Spiral Orbital Wrapper excels in securely wrapping a wide range of product shapes with its versatile and precise film application. This machine uses a spiral ...

The Orbital Ring Wrapper is specially designed to accommodate the wrapping needs of ring-shaped and cylindrical products. This machine efficiently applies stretch...

Horizontal orbital wrappers are advanced packaging machines designed for efficient and secure wrapping of products in various industries. They utilize a unique or...

An Orbital Wrapping Machine is a game-changer for factories that handle long, irregular, or delicate products. Whether you are wrapping pipes, rods, or other elongated items, this machine ensures secure and uniform packaging that protects your goods during storage and transit. Unlike traditional methods, an orbital stretch wrapper automates the wrapping process, reducing manual labor while increasing productivity.

Its versatility makes it an ideal solution for industries requiring tailored packaging solutions for pipes or other custom applications. With a customizable orbital wrapping machine, you can adapt the equipment to fit your product dimensions, ensuring precise and reliable wrapping every time. For businesses looking to streamline operations and enhance product safety, an orbital wrapper delivers unmatched efficiency and protection.

Feel free contact us at any time.

Choosing the right orbital packaging equipment is essential to ensure it meets your operational goals and product requirements. Here are the critical factors to consider:

Whether you need an orbital wrapper for long products or a customizable orbital wrapping machine for unique applications, selecting the right equipment ensures smoother workflows and superior packaging quality.

Feel free contact us at any time.

Choosing the right supplier for your orbital wrapping machine is just as important as selecting the machine itself. A reliable supplier provides top-quality equipment and ongoing support to meet your operational needs. Here's what to look for:

By selecting a trusted supplier offering high-quality, adjustable orbital stretch wrapping equipment, you can future-proof your operations while maximizing efficiency and ensuring consistent, professional packaging results.

Feel free contact us at any time.

When it comes to selecting a supplier for an orbital wrapping machine, the choice can greatly influence your operational efficiency and cost management. In recent years, Chinese manufacturers have increasingly become the go-to choice for companies worldwide. Known for competitive pricing, technological advancements, and customization options, China’s manufacturing industry offers high-quality machinery tailored to various industrial needs. But what makes Chinese manufacturers so advantageous for this type of specialized equipment? Let's explore why choosing a Chinese orbital wrapping machine manufacturer could be the best investment for your business.

China’s industrial manufacturing capabilities go beyond cost savings. Manufacturers provide advanced technology, streamlined production processes, and the capacity for rapid scaling and customization, making them uniquely positioned to meet the needs of global industries. These attributes have put China at the forefront of the orbital wrapping machine market, ensuring a balance of affordability and innovation that is hard to find elsewhere.

In addition to cost efficiency, Chinese manufacturers offer a level of customization and adaptability that aligns with industry-specific requirements. This flexibility is invaluable, as it ensures the machine’s seamless integration into existing workflows, allowing businesses to enhance their production efficiency with minimal adjustments.

[claim] Chinese orbital wrapping machine manufacturers stand out by offering affordable, high-quality, and customizable machinery. Combining advanced technology with competitive pricing and tailored manufacturing solutions, they provide exceptional value to companies looking to improve efficiency and reduce operational costs.

Choosing a Chinese manufacturer often means access to orbital wrapping machines at highly competitive prices, without a compromise on quality. This affordability stems from economies of scale, established supply chains, and efficient labor costs, allowing companies to acquire high-quality equipment without stretching their budgets. For businesses looking to optimize costs, Chinese manufacturers offer machines that meet global standards of quality at a fraction of the cost, providing a major advantage over other regions.

The affordability of Chinese-made machines extends beyond the initial purchase. Many manufacturers provide comprehensive after-sales support, parts replacement, and repair services, which reduces the need for costly third-party maintenance. This support network minimizes overhead expenses related to equipment upkeep and can substantially improve return on investment (ROI). By minimizing both purchase and maintenance costs, working with a Chinese manufacturer enables companies to maximize their equipment’s lifetime value.

For companies needing multiple units or frequent equipment updates, Chinese manufacturers often offer favorable terms like bulk purchase discounts and flexible payment options. These discounts benefit businesses that require large quantities of machines or plan to scale up in the near future. With these arrangements, companies can manage their cash flow effectively while ensuring their operations are well-equipped with necessary machinery. Bulk purchasing offers immediate savings, allowing businesses to affordably expand or replace equipment as needed.

Chinese manufacturers have made significant investments in advanced automation technologies, enabling orbital wrapping machines to operate with heightened precision and efficiency. Modern machines incorporate intelligent control systems, allowing for smooth, automated operations with minimal human intervention. This reduces labor costs, minimizes errors, and improves consistency. With automated features such as touch-screen controls, programmable settings, and real-time system monitoring, these machines offer an effortless operation that supports high productivity while maintaining excellent wrap quality.

Safety is paramount in industrial machinery, and Chinese manufacturers are diligent about including safety mechanisms in their orbital wrapping machines. From automatic shutdown systems to safety enclosures and emergency stop functions, these machines are designed to operate safely even in demanding environments. This focus on safety ensures the well-being of employees and helps prevent product damage during the wrapping process. These robust safety features not only create a safer workplace but also contribute to a reliable, accident-free production line.

In line with the global trend toward Industry 4.0, many Chinese manufacturers incorporate IoT (Internet of Things) capabilities and smart technology into their orbital wrapping machines. These machines can connect seamlessly with centralized data systems, offering remote monitoring, data analytics, and predictive maintenance. This connectivity provides real-time insights, enabling businesses to monitor machine performance, identify inefficiencies, and proactively address potential issues before they escalate. For companies aiming to modernize their operations, Industry 4.0-ready machines from China offer a future-proof investment that keeps their production lines running smoothly and efficiently.

One of the significant advantages of working with Chinese manufacturers is their flexibility in customization. These manufacturers understand that every facility has unique needs, from layout constraints to specific packaging requirements. Chinese suppliers often offer tailored adjustments to orbital wrapping machines, such as changes in size, wrap speed, or even specialized materials for handling delicate items. This customization ensures that the machine integrates seamlessly into existing production lines, enhancing overall workflow without the need for major adjustments.

Beyond basic adjustments, Chinese manufacturers can incorporate features such as variable wrapping modes, tension control, and compatibility with different wrap films. These advanced options allow businesses to use the machines for various products, improving efficiency and versatility. For instance, some orbital wrapping machines come with adjustable settings that accommodate a wide range of items, from large pallets to smaller, more fragile products. By customizing the machine’s functionality, companies can achieve optimal wrapping results, ensuring that every package is secure, regardless of its shape or size.

Investing in a customized orbital wrapping machine may require a higher upfront cost, but it can provide substantial long-term benefits. Tailored equipment operates precisely according to your facility’s demands, which reduces downtime, improves throughput, and eliminates inefficiencies. Additionally, customization can future-proof the equipment, ensuring that as your production needs evolve, the machine can adapt, supporting scalability and flexibility over time. For businesses looking to optimize productivity and minimize long-term costs, a custom-built machine is a strategic investment that aligns with both current and future operational goals.

Chinese manufacturers have implemented stringent quality control measures to ensure that each orbital wrapping machine meets high performance and durability standards. From materials selection to final assembly, every component undergoes rigorous inspection. This quality focus allows Chinese manufacturers to produce machines that can withstand demanding industrial environments and perform reliably over the long term. Businesses benefit from machinery built to exacting standards, reducing the need for frequent repairs or replacements.

To meet global market demands, many Chinese manufacturers comply with international certifications such as CE, ISO, and UL standards. These certifications signify adherence to quality and safety benchmarks recognized worldwide. For companies looking to export or operate in regions with strict regulatory requirements, working with a certified Chinese manufacturer ensures that their equipment meets the necessary compliance standards, facilitating smoother transactions and instilling confidence in the machinery’s quality.

Chinese manufacturers also recognize the importance of after-sales support and typically offer robust service packages, including technical assistance, training, and extended warranties. This support is invaluable, as it ensures that companies can rely on the manufacturer for guidance, replacement parts, and repairs. With dedicated after-sales support, businesses can maintain their equipment with confidence, knowing that assistance is readily available should any issues arise. This commitment to customer service further reinforces the reliability and value of partnering with a Chinese manufacturer.

In choosing an orbital wrapping machine, selecting the right manufacturer is essential to maximizing value and meeting specific operational needs. Chinese manufacturers stand out in this field, offering not only cost efficiency but also advanced technology, customization capabilities, and reliable quality standards. Whether it’s the affordability and flexibility of bulk discounts, the cutting-edge automation features, or the tailored customization options, Chinese manufacturers deliver a holistic solution for businesses looking to improve efficiency and reduce costs.

[claim] Chinese manufacturers of orbital wrapping machines provide a unique blend of affordability, advanced technology, and tailored support, making them an ideal choice for companies worldwide. By combining quality and innovation with competitive pricing, they offer solutions that drive productivity and enhance operational efficiency for businesses of all sizes.

Our team will reply in 24 hours

![]() Email: info@fhopepack.com

Email: info@fhopepack.com

![]() Whatsapp: 0086-13951501635

Whatsapp: 0086-13951501635

I'm online now.