Click to Chat

I'm online now.

Fhopepack Innovation

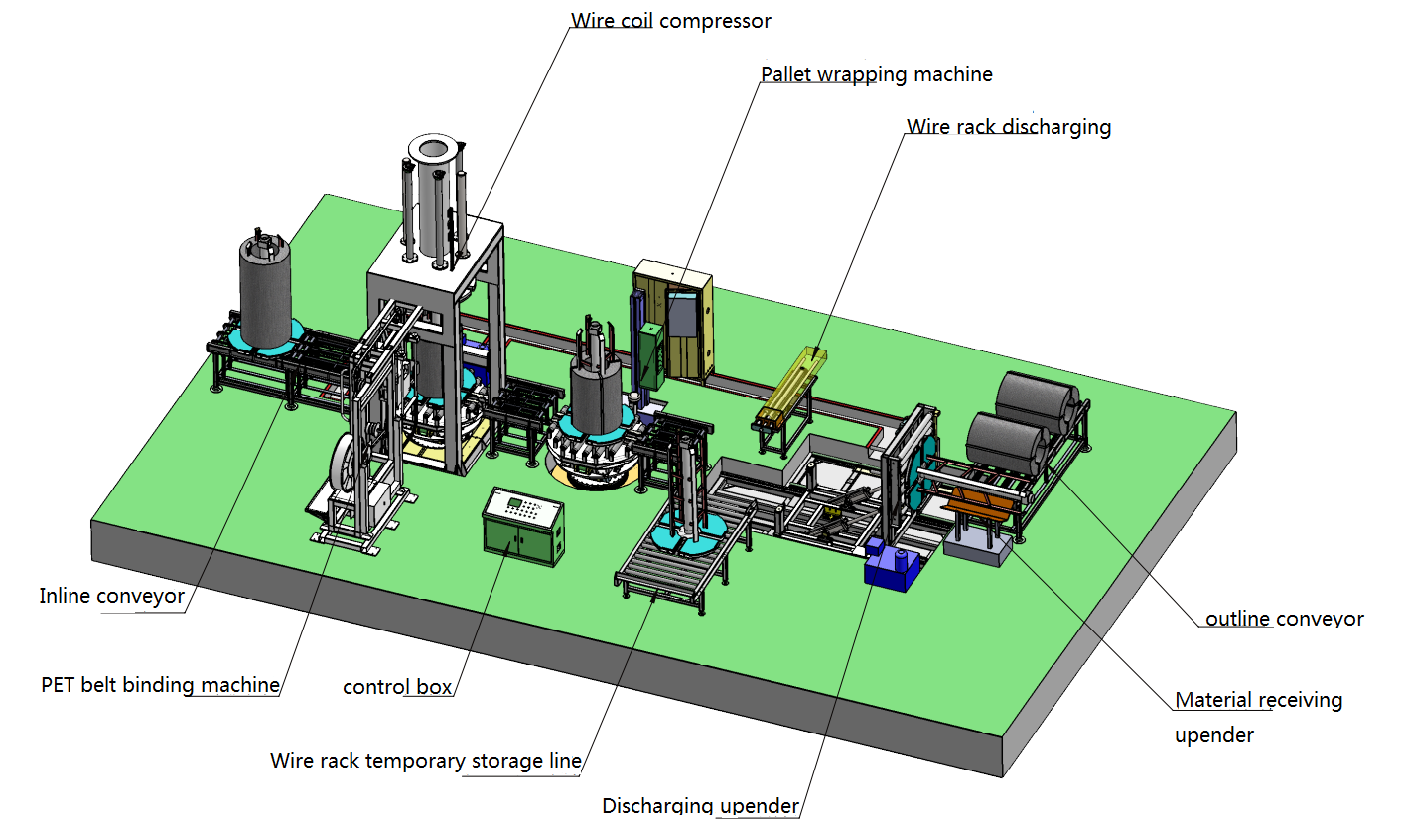

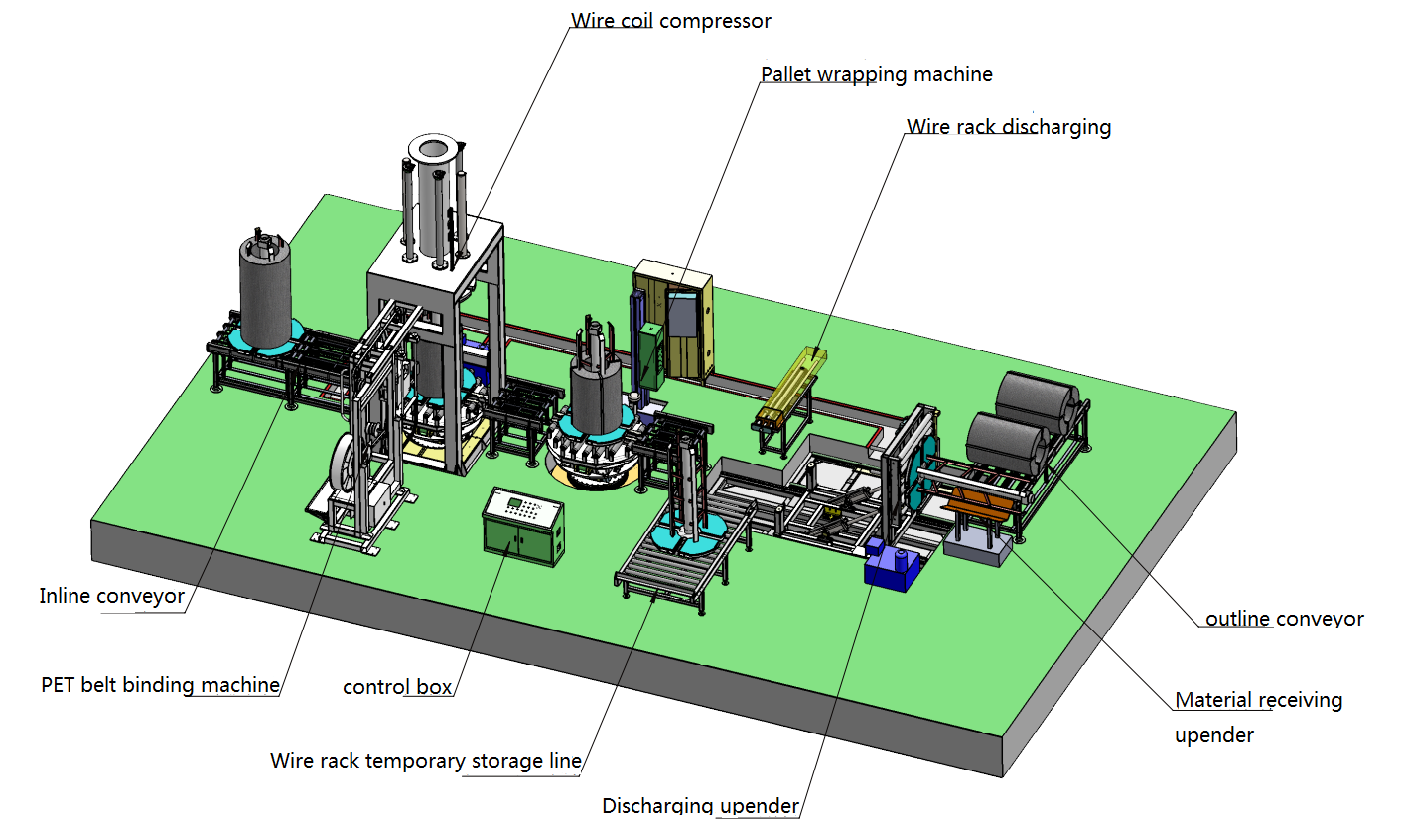

Both semi-automatic and full-automatic type can be provided. Specific design and plan will be made by our engineering team according to the data provided by the customers. From compacting to strapping to wrapping, our packing line will give a perfect package as you want.

The automatic wire coil compacting and strapping line is a solution for substantial production demand. Well packed product is able to against all the possible erosion. High water proof and dust proof quality keeps your product away from water spots and dust or other substance which may affect the quality of your commodity.

Technical specifications&performance:

We are responsible for the whole equipment design, the equipment integrity, and the completeness& accuracy of all the documents.

All of the design are based on Metric standard and comply with the existing ISO standards.All bearings are adopted according to International standards.

For more information on this see our related resource:

Efficiently handling wire coils for transport or storage is a constant challenge in the metalworking and manufacturing sectors. Issues such as coil deformation, suboptimal loading density, and labor-intensive processes can all impact a company’s bottom line. The wire coil compacting and strapping machine offers a robust solution: it compacts wire coils, applies PET or steel straps under precise tension, and seamlessly integrates with conveyors to reduce manual handling. This article explores how the machine’s technical architecture, combined with advanced automation and fluid power control, can optimize throughput, reduce damage, and improve workplace safety.

By addressing these functionalities, the wire coil compacting and strapping machine significantly cuts handling time, ensures a more consistent strapping profile, and offers improved overall reliability.

Precision Positioning (±0.5 mm)

A vision system or laser-guided sensors can be installed to identify the coil’s exact position on the conveyor. This tight tolerance prevents misalignment, which could otherwise cause coil offset or strapping errors.

Enhanced Conveyor Material

Many systems use polyurethane-coated belts with embedded steel wire reinforcement. This design provides robust gripping performance while resisting cuts from sharp wire ends or edges.

Case Study

At a major steel manufacturing plant, a fully integrated conveyor system equipped with a robotic arm increased single-shift throughput to 800 wire coils. Maintenance needs also dropped, thanks to reduced mechanical wear from manual lifting and fewer forklift collisions.

Variable Pressure Range (10–18 MPa)

An intelligent hydraulic press applies adjustable pressure based on coil diameter and wire grade. Typically, operators (or an automated PLC program) set the pressure parameters for different wire types—thicker gauge wire demands higher compaction forces than thinner strands.

Servo Motor Energy Savings

Compared to pneumatic systems, servo-driven hydraulic pumps can save up to 35% in energy consumption. The servo motors only power the pump when movement or pressure is required, significantly cutting idle-time power draw.

Overload Protection

Some manufacturers use patented overload protection systems (e.g., Patent No.US7362066B2), providing real-time monitoring of pressure spikes. If the compaction head senses a load increase beyond safe thresholds, the system halts immediately to avoid damaging the coil or the machinery.

PET vs. Steel Strap

Dynamic Tension Control (±2% Error Margin)

A closed-loop sensor system continuously measures strapping tension. Should the tension deviate from the setpoint, the machine auto-corrects within a ±2% margin. This level of precision ensures coils retain a tight, stable shape for transport and storage.

Rapid Coil Band Change

Many advanced machines integrate a quick-change magazine, letting operators load fresh coils of strap quickly. The system checks for correct strap size—commonly 13 mm or 19 mm—before automatically threading it into the tensioning head.

Compact Footprint

This solution can occupy up to 40% less floor space than older equipment—particularly beneficial for congested production floors. For example, a 2.1 m × 1.8 m footprint can handle comparable loads to bulkier legacy systems.

Digital Twin Pre-Commissioning

By simulating the machine’s workflow on an IoT-enabled digital platform, installation times drop by 60%. Errors in layout or line speed synchronizations can be caught early, reducing onsite rework.

Predictive Maintenance Alerts

Embedded sensors feed real-time data into a predictive maintenance module, issuing early warnings for wear on hydraulic seals, conveyor belts, or strapping heads. This approach reduces unplanned downtime to <2% per year.

Broad Material Compatibility

Different wire diameters—anywhere from Φ5 mm to Φ30 mm—can be compacted and secured within the same machine. Operators simply select the appropriate settings through the HMI panel.

Energy Efficiency

Certified under ISO 50001, the machine’s integrated servo-hydraulic system cuts energy usage by an average of 23% compared to legacy pneumatic-only systems.

Custom Software Interface

For modern manufacturing lines that rely on ERP or MES platforms, the machine offers an open API or custom driver. Production data on coil throughput, strapping tension, and downtime logs can integrate directly with higher-level software.

Wire Manufacturing Plants

By boosting coil density and cutting manual labor, these facilities can reduce shipping volume per coil. In many cases, 45% more coils fit into a standard container once each coil has been compacted and reliably strapped.

Port Logistics Hubs

PET straps are especially popular in ports that handle intermodal shipping. They eliminate the need for fumigation (often required for wooden pallets or other organic materials), aligning well with EU 2016/2031 regulations.

Scrap Metal Recycling

In recycling operations where heavy or irregularly shaped metal scrap is bound in wire coils, steel straps provide exceptional holding strength. This avoids hazards from loose or bulging bundles.

Automotive and Aerospace Suppliers

Precision is paramount in industries using specialized wire materials. The machine’s dynamic tension control helps maintain uniform coil geometry, reducing rework or wire tangles that can derail automated assembly lines.

Companies have reported:

| Parameter | Specification |

|---|---|

| Compacting Force | 80–350 kN (programmable) |

| Cycle Time | ≤22 seconds/coil (includes strapping) |

| Power Supply | 380 V / 50 Hz ±10% |

| Noise Level | <75 dB(A) @ 1 m distance |

| Protection Rating | IP54 standard (custom IP65) |

| Supported Strap Width | 13 mm or 19 mm (PET/Steel) |

| Conveyor Load Capacity | Up to 2,000 kg/m |

These parameters provide a baseline understanding. Actual configurations may vary based on site conditions, coil dimensions, or advanced options (e.g., specialized sensors, custom hydraulic modules).

Is the machine compatible with non-cylindrical or oddly shaped coils?

Yes. Certain models incorporate side-pressure mechanisms, enabling them to compact and strap rectangular or elliptical wire bundles.

How does PET strap fare in humid or outdoor conditions?

PET straps can be manufactured with UV-resistant additives (meeting ASTM D5278 standards), maintaining tensile properties even in harsher climates.

What is the recommended hydraulic maintenance schedule?

Most suppliers advise using VG46 anti-wear hydraulic oil and replacing it every 2,000 operating hours. Filters should also be inspected for particulates quarterly.

Do I need proprietary strapping consumables?

In general, these machines accept standard market straps in either PET or steel, provided the width (13 mm or 19 mm) and coil diameter are within recommended limits.

How is remote troubleshooting handled?

Many systems feature an industrial-grade TeamViewer or similar remote service interface. Technicians can access the HMI, read error logs, and guide local staff through corrective measures without the need for onsite travel.

A wire coil compacting and strapping machine is more than just a piece of equipment; it is a strategic investment that bolsters product integrity, improves worker safety, and heightens logistical efficiency. By integrating seamless conveyor systems, smart hydraulic presses, and dual-mode strapping options, you can expect streamlined operations with minimal downtime. The potential for 90%+ efficiency gains is within reach, especially when aligned with predictive maintenance tools and robust Industry 4.0 data integration.

To learn more about the specifications, or to discuss how this technology can be customized for your facility’s unique needs, consider:

With advancements like digital twin modeling and predictive maintenance, a wire coil compacting and strapping machine stands as a catalyst for modern manufacturing excellence. Whether you operate in steelmaking, automotive component production, or large-scale logistics, the right compacting-strapping solution can reshape your operational efficiency—turning once-daunting coil handling processes into a smoothly orchestrated part of your manufacturing line.

I'm online now.