Click to Chat

I'm online now.

Fhopepack Innovation

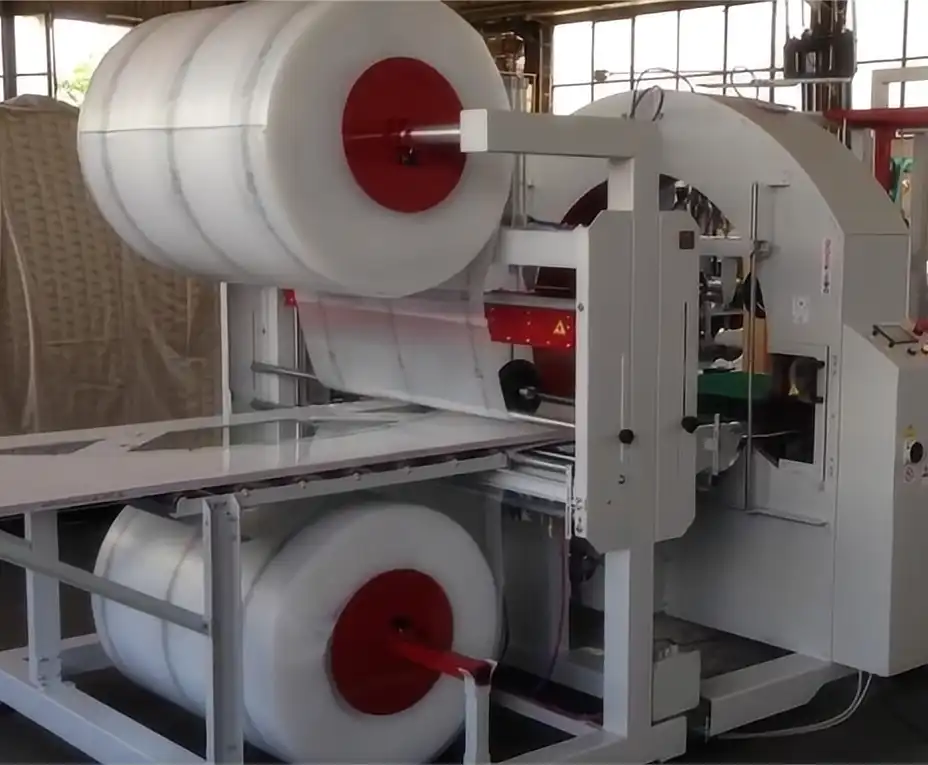

Our profile orbital wrapping machine offers high-speed wrapping, eliminating the need for manual packaging and increasing productivity. The most important feature of our machine is security, providing users with a safe and reliable wrapping solution. With its advanced features and efficient operation, our profile orbital wrapping machine is an ideal choice for businesses seeking to streamline thei

Description:

Features:

Note: Can be designed according to your specification.

Investing in a profile horizontal orbital wrapping machine can significantly improve packaging efficiency, product protection, and overall operational productivity. However, to fully realize these benefits, proper delivery, installation, and setup are crucial. Ensuring that the machine is delivered and installed correctly will minimize downtime, optimize performance, and help you achieve maximum efficiency from day one.

This article will guide you through the steps involved in the delivery and setup process, from pre-installation preparations to machine configuration and operator training.

Before your horizontal orbital wrapping machine arrives, it’s essential to prepare your facility to ensure smooth delivery and installation. Taking care of these steps in advance helps avoid delays and reduces the risk of complications during setup.

The first step in preparing for your wrapping machine's arrival is ensuring that you have enough space to accommodate it. Consider the machine's dimensions, including the wrapping ring, conveyor system, and any additional components. The machine should be positioned in a location that allows easy access for maintenance and operation, with sufficient clearance for products to move through the wrapping area.

It’s also important to ensure that the workspace is equipped with the necessary utilities, such as electrical connections and air supply (if required by the machine). These utilities should be installed before the machine arrives to avoid installation delays.

Once you’ve selected a location for the machine, ensure that there is a clear delivery path for moving it from the unloading area to its final position. This path should be free from obstacles, such as other equipment or inventory, to allow for smooth transportation of the machine within your facility. If necessary, make arrangements for specialized equipment, such as forklifts or cranes, to move the machine safely.

The delivery of a horizontal orbital wrapping machine is a complex process, often involving large and heavy equipment. Coordinating with the supplier ensures that the delivery process goes as smoothly as possible.

Work closely with your supplier to schedule a delivery date and time that aligns with your operational schedule. It’s important to have key personnel, such as your maintenance or engineering team, available during the delivery to supervise the unloading and positioning of the machine.

When the machine arrives, conduct a thorough inspection to ensure that it is in good condition and free from any damage that may have occurred during transit. Verify that all parts and components are present, and cross-check the shipment with the packing list provided by the supplier. Reporting any damage or missing parts immediately will help expedite the replacement process if necessary.

After the machine has been delivered and positioned in its designated area, the next step is the installation and setup process. Proper installation is key to ensuring that the machine operates efficiently and without issues.

Some wrapping machines may arrive partially disassembled for easier transport. In this case, the machine components will need to be reassembled on-site. The supplier typically provides an installation guide or manual, which outlines the assembly process step by step. Depending on the complexity of the machine, the supplier may also send a team of technicians to assist with the installation.

Common assembly tasks include:

After the machine is assembled, the next step is to connect it to the necessary utilities. Most orbital wrapping machines require an electrical connection, while others may also need compressed air for certain functions, such as film cutting and sealing.

Ensure that the power supply meets the machine’s specifications, as outlined by the manufacturer. It’s recommended to have a qualified electrician handle the electrical connections to avoid any safety hazards or potential damage to the machine.

Once the machine is assembled and connected to power, it needs to be calibrated and configured to meet your specific packaging needs. Proper calibration is critical for achieving maximum efficiency and ensuring that the machine wraps products consistently and securely.

The first step in configuring the machine is adjusting the film tension and wrapping speed. These settings depend on the type and size of the products being wrapped. For example, delicate items may require lower tension to avoid damage, while sturdier products may need higher tension for a tight wrap.

Most high-end machines feature automatic tension control, which adjusts the film tension based on the product’s size and weight. This feature can help improve efficiency and reduce the need for manual adjustments during operation.

Next, configure the machine’s wrapping patterns according to your packaging requirements. Some products may only need partial wrapping, while others may require a full wrap with multiple layers of film. Many modern machines offer customizable wrapping programs that allow you to save specific settings for different product types, ensuring consistency and speed during operation.

Once the machine is installed and configured, it’s essential to train your operators on how to use it effectively. Proper training ensures that operators can run the machine safely and efficiently, maximizing productivity while minimizing the risk of accidents.

Most suppliers offer operator training as part of the installation package. This training typically covers the following topics:

Ensure that all operators receive comprehensive training before using the machine to avoid operational issues and safety hazards.

Safety is a top priority when working with large machinery like a horizontal orbital wrapping machine. Ensure that operators are familiar with the safety features of the machine, such as emergency stop buttons, sensors, and interlocks. Additionally, establish safety protocols for handling products and maintaining the machine to prevent accidents and injuries.

After the machine is up and running, regular maintenance is critical to keep it operating at peak efficiency. Neglecting maintenance can lead to breakdowns, reduced performance, and costly downtime.

Perform routine maintenance tasks, such as:

Many modern machines come with built-in diagnostic systems that alert operators when maintenance is needed. Use these systems to stay on top of repairs and prevent small issues from turning into major problems.

In addition to routine maintenance, schedule preventive maintenance at regular intervals. Preventive maintenance includes more in-depth inspections, such as checking the motor, bearings, and sensors for wear and tear. Most manufacturers recommend performing preventive maintenance every six months or as outlined in the machine’s manual.

To fully maximize the efficiency of your profile horizontal orbital wrapping machine, it’s essential to leverage the advanced features that many modern machines offer. These features not only streamline the wrapping process but also optimize material usage, reduce labor involvement, and improve overall packaging quality. By incorporating these technologies, businesses can significantly improve their packaging operations while lowering long-term costs and enhancing productivity.

One of the most effective features for improving efficiency is pre-stretch film technology. This innovation stretches the film to a predetermined length before it is applied to the product. Pre-stretching the film not only enhances its tensile strength, ensuring a more secure wrap, but it also reduces the amount of film required per unit. This leads to significant cost savings on materials, particularly for high-volume operations. Additionally, pre-stretch film offers greater consistency in the wrap, reducing the risk of product damage during handling and transport. Over time, these benefits translate into better product protection and lower packaging expenses, making pre-stretch film technology a must-have for businesses seeking to maximize efficiency.

Another key feature in modern orbital wrapping machines is the integration of smart sensors and automation technology. These sensors detect the dimensions and shape of the product as it enters the wrapping zone, allowing the machine to automatically adjust the film tension, wrapping speed, and pattern based on the specific requirements of each product. By fine-tuning these settings in real-time, the machine minimizes material waste and ensures consistent, high-quality wrapping without operator intervention. This level of automation not only improves packaging precision but also significantly reduces the need for manual adjustments, freeing up operators for other tasks. Moreover, automated systems help prevent over-wrapping or under-wrapping, which can lead to material waste or inadequate protection, further optimizing the packaging process for maximum efficiency

.

The successful delivery and setup of a profile horizontal orbital wrapping machine are crucial to achieving maximum efficiency in your packaging operations. By preparing your facility, coordinating with the supplier, and properly configuring and maintaining the machine, you can ensure that your investment delivers long-term value.

Proper operator training, safety protocols, and the use of advanced machine features like pre-stretch film technology and automation will further enhance your operational efficiency. With the right setup and ongoing maintenance, your wrapping machine will streamline packaging, reduce material costs, and improve overall productivity

I'm online now.