Click to Chat

I'm online now.

Fhopepack Innovation

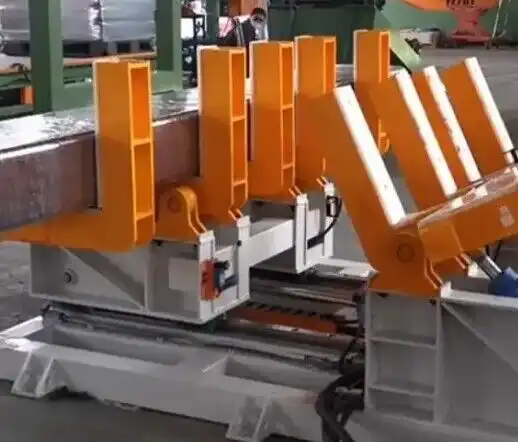

A Heavy Capacity Hydraulic Flipper was designed and manufactured to rotate Max 12 T steel sheet from the vertical position to the horizontal / horizontal to vertical position. To assure safety, even transition and smooth operation during the tilting , the flipper features durable acting hydraulic cylinder. B asic description : Equipment name : MOLD FLIPPER Quantity: 1set Product info: piece of s

A Heavy Capacity Hydraulic Steel Sheet Flipper was designed and manufactured to rotate Max 12 T steel sheet from the vertical position to the horizontal/horizontal to vertical position. To assure safety, even transition and smooth operation during the tilting, the flipper features durable acting hydraulic cylinder.

Basic description:

Equipment name:Steel Sheet Flipper

Quantity: 1set

Product info:

piece of steel thickness 50-300 mm size 1800x2500-2800 mm

Max Weight =12T

Power supply 380V 3P 50Hz

Basic parameters of the machine:

1) Two working tables for 90 degree turning the mold.

2) Heavy designed structure with long life.

3) Quality hydraulic system with cylinder synchronize device

4) Speed of turning is adjustable.

5) Mechanical and electric stop block for safety operation.

6) Control panel or Remote operation.

7) Automatic stop. And the machine can be stop any angle with pressure keeping.

8) Smooth, accurate, vibration-free motion.

9) Max.pressure 15Mpa. With Max.Allowance20Mpa

10)Actuation: double acting hydraulic cylinders..

11) Way of loading: via fork lift / crane/ hoist.

12) control: pedestal mounted hydraulic power unit up-down.

13) Automatic position lock up and position soft reset for accident power off.

14)Working table size; Working table size A: 500x1800 mm B: 500x1800 mm

15) Soft cover shield for operation protection.

Technical parameter:

|

Type |

Dimension(mm) |

Max Flipping load |

Motor Output |

Machine Weight |

Oil reservoir |

||

|

L |

W |

H |

|||||

|

FPFT-12 |

4600 |

2500 |

1400 |

12 |

8.0 |

4.5 |

60 |

Note: The machine size with drawing will be provide after designing:

Working cycle:

Load the product on → Table B flip 90 degrees counterclockwise upright ready to receive the product → Table A with product clockwise flip 85 degrees and move forward (photoelectric sensing stop) → Table A with product continue to flip to slightly more than 90 degrees → product from Table A lean to Table B → Table B clockwise flip 5 degrees with product→ Table A move back and flip back counterclockwise to the original horizontal position → Table B with product continue to flip clockwise back to the original horizontal position → Unload product from Table B→ One working cycle ends

I'm online now.