Click to Chat

I'm online now.

Fhopepack Innovation

At Fhope, we offer a range of automatic hose coil packaging solutions, including hose coiling machines for HDPE pipes and corrugated coil packaging machines from coiling to stacking. Our comprehensive packaging line is designed to streamline the packaging process and increase productivity, providing businesses with a cost-effective and efficient solution for their packaging needs. With advanced fe

Hose coil automatic packaging line, can including coiling machine, Auto conveyor line, Auto coil wrapping machine, coil strapping machine...

And coil stacking & pallet wrapping machine can be available for fully automatic packaging. Which can connect with packaging line for Inline packaging. All kind of plastic coil package solution, such as PVC/CPVC/PEX.... Machine size can be modified according requirements.

The Fhope automatic hose pipe coiling machine is a highly efficient and intelligent solution designed for coiling plastic pipes such as PVC, CPVC, PEX, and other flexible tubing. Ideal for high-volume production lines, it integrates automatic feeding, tension control, length measuring, layer winding, cutting, and coil forming into a streamlined process—ensuring consistent, neat, and professionally packed hose coils.

Online Pipe Feeding: Seamlessly connects with the extrusion line for continuous inline pipe coiling.

Tensioner & Counter: Ensures precise pipe length measurement and consistent tension during coiling.

Automatic Pipe Loading to Coiling Station: No manual operation is required—pipe is automatically guided to the coiling unit.

Pipe Head Clamping & Rotating for Coiling: The pipe head is automatically clamped, and the rotating system forms tight, even coils.

Automatic Layering: Intelligent control enables organized, multi-layer coiling for better packing presentation.

Automatic Length Detection & Cutting: Once the pipe reaches the pre-set length, the system cuts it cleanly and accurately.

180° Horizontal Turning System: After coiling, the finished coil is rotated for strapping, improving line efficiency.

Optional Automatic Strapping: Integrates with a strapping system to apply 4 or 6 straps per coil, ensuring a secured and stable product.

Labor Saving & Productivity Boost: Replaces manual labor, reduces errors, and significantly improves operational efficiency.

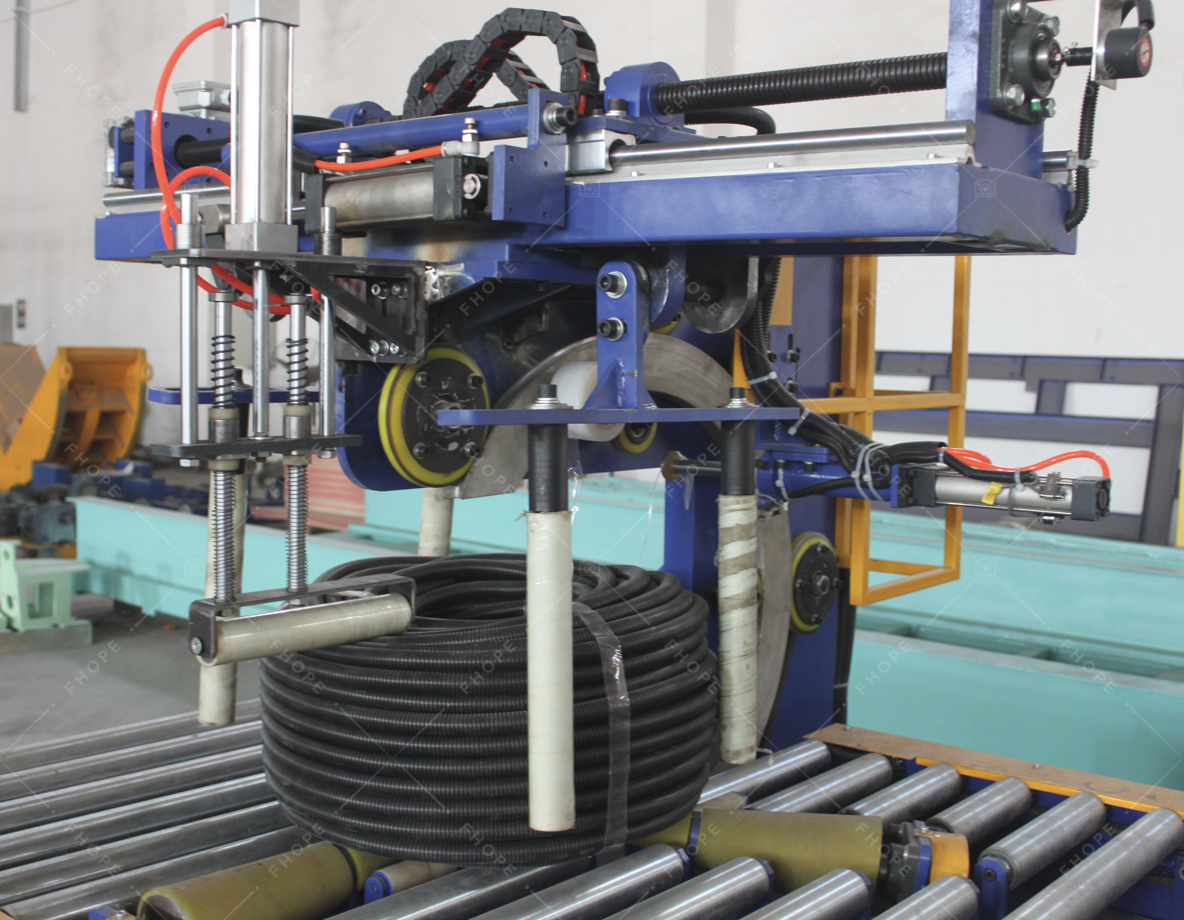

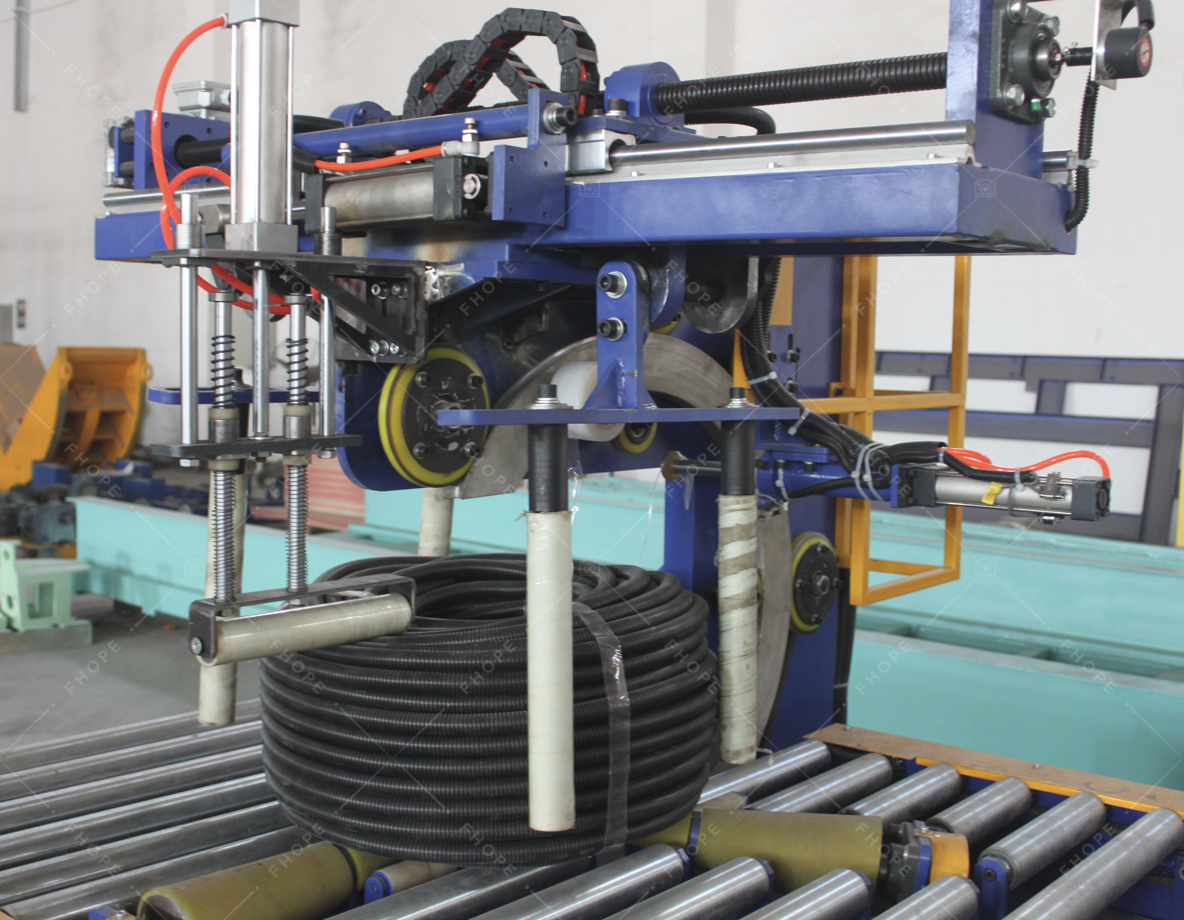

The automatic hose/pipe coil wrapping machine is specially designed for stretch film wrapping of coiled products such as plastic hose, PEX pipe, PVC tubing, and other coiled materials. It offers a reliable and consistent solution for protecting pipe coils from dust, moisture, scratches, and environmental damage during storage and transportation.

This machine can be connected with the coiling and strapping system to form a fully automated inline packaging line—significantly increasing efficiency while reducing manual handling.

Inline Integration: Can be seamlessly connected with the hose coiling and strapping machines to achieve a continuous automatic packaging process.

Automatic Coil Positioning: The wrapped coil is automatically centered and positioned for precise wrapping without human assistance.

Film Tension Control: Adjustable film tension ensures tight and uniform wrapping around the coil surface.

Variable Wrapping Speed: Speed can be customized to suit different coil sizes and film thickness requirements.

Intelligent PLC Control: Easy-to-use touch screen interface with preset programs for different coil sizes and wrapping patterns.

Enhanced Protection: Stretch wrapping offers superior protection from moisture, dirt, and surface damage.

Our technicians will design and produce your machine according to your list of requirements and provide any technical support and after-sales service required without having to pay for expensive travel expenses.

Fhope coil Packaging machinery is always striving to provide high quality equipment to serve the needs of customers around the world.

In today’s competitive manufacturing environment, automating downstream processes is no longer an option—it’s a necessity. For hose and pipe manufacturers, the packaging process is often a bottleneck. But with the latest generation of automatic hose coil packaging lines, the entire workflow—coiling, strapping, wrapping, stacking, and palletizing—can be managed by a single operator overseeing multiple machines.

This level of automation not only streamlines production but also reduces labor dependency, increases throughput, and ensures consistent packaging quality—key factors in modern lean manufacturing systems.

Hose coils—whether PVC, PEX, CPVC, or PE—require careful handling post-extrusion. Improper coiling or inconsistent strapping can lead to product deformation, logistics issues, or damaged inventory. Traditional manual packaging is time-consuming and inconsistent.

An inline hose coil packaging system solves these challenges by standardizing every step in the packaging process. Here's a look at what that system includes:

Function: Automatically receives extruded hose, measures length, coils into predefined dimensions, and prepares for downstream strapping.

Key Features:

Online feeding from the extrusion line

Programmable coil sizes and lengths

Automatic pipe cutting upon target length

Horizontal 180° rotation for strapping transfer

Function: Applies 4 or 6 tensioned straps around the coil to maintain shape and structure.

Benefits:

Eliminates manual banding

Uniform strap placement

Adjustable strap tension via HMI

Suitable for various coil diameters and widths

Function: Wraps each strapped coil with protective stretch film or paper to guard against dust, moisture, and scratches.

Features:

Tension-controlled film application

Automatic film clamping, cutting, and wiping

Pre-programmed wrapping patterns

CE-compliant design

Function: Stacks finished coils onto pallets, organizes by layer, and prepares for outbound shipping or storage.

Advantages:

Robotic arm or lift system for accurate placement

Pallet configuration options (1x1, 2x2, etc.)

Compatible with pallet stretch wrappers

Function: Once stacking is complete, a fully loaded pallet is stretch wrapped for stability during transportation.

Specs:

Adjustable film tension and wrap layers

Turntable or rotary arm design

PLC-controlled wrap cycle

| Section | Max Capacity | Control Method | Labor Required |

|---|---|---|---|

| Coiling & Cutting | Up to 6 coils/min | PLC + Servo Motor | 0 |

| Strapping Unit | 4–6 straps per coil | Auto + Adjustable | 0 |

| Wrapping Machine | 20–30 coils/hr | HMI + Sensors | 0 |

| Stacking & Palletizing | 8–10 coils/pallet | Servo + Pneumatic | 0 |

| Pallet Wrapping | Up to 40 pallets/day | PLC + Pre-stretch | 0 |

| Total Line Supervision | Entire system | Centralized HMI | 1 Operator |

Thanks to the integration of centralized control systems, the entire packaging line can be monitored and adjusted in real-time via a single HMI panel. This reduces the number of floor staff required while enhancing traceability and responsiveness. Error alerts, real-time data, maintenance prompts, and production tracking are all accessible from one interface.

“A single operator can now oversee an entire factory’s hose packaging process from end to end,” says a senior automation engineer at Fhope. “It’s about redefining efficiency—not just adding machines.”

Each packaging line is modular and scalable, designed around your production capacity and coil specifications. Whether you're processing 16mm flexible tubing or 75mm water hose, the system can be tailored to match your product dimensions and throughput goals.

Optional integrations include:

Label applicators

Barcode scanners

MES/ERP system links

Remote diagnostics and IoT monitoring

Reduced Labor Cost: From 5+ workers to just 1

Improved Consistency: Every coil, every pallet—uniform and professional

Minimized Downtime: Automated transitions between steps

Traceability: Batch tracking, reporting, and QA-friendly design

Space-Saving Layout: Compact and linear footprint for optimized factory layout

Automation isn’t just about speed—it’s about control, reliability, and long-term value. A fully automatic hose coil packaging line transforms what used to be a labor-intensive process into a smart, centralized operation that maximizes output while minimizing manual input.

For pipe and hose manufacturers focused on lean production, packaging automation is no longer just an upgrade—it’s a competitive advantage.

???? Interested in a custom solution? Contact Fhope to design an automatic hose packaging line tailored to your plant layout and production goals.

I'm online now.