Click to Chat

I'm online now.

Fhopepack Innovation

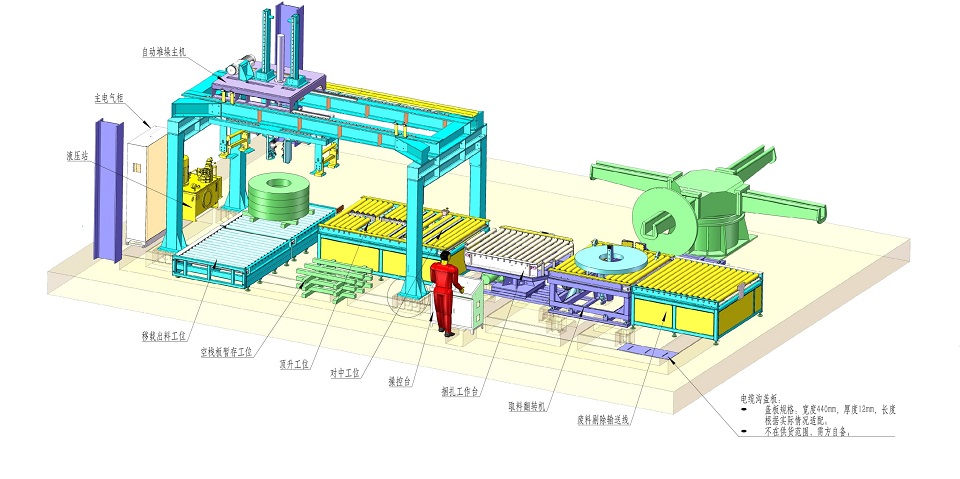

The automaitc slitting coil handling system include: Turnstile, coil down ennder, coil turntable for strapping and coil stacking machine. It is able pick up the coil and turning 90 degree for chaning ID to wall into ID to sky. So that it is easy stacking coiling on pallet by automatic stacker one by one.

It is automatic slit coil packaging system that includes turntile, coil down ender, coil weighing machine, coil strapping machine and stacking equipment to handling packed slit coil from centering conveyor to pallet one by one.

The system is able help to Minimized the manually operation in handling the heavy coil which is more safety and efficiency way to stacking the steel coil.

Coil move to the in-feeding station, automatic centering and raising the coil

Automatic coil pick up and lifting

Automatic palletizing the coil one by one on the pallet.

Pallet out-feeding.

A. Centering&Lifting table

1) Roller conveyor for moving the coil

2) Centering device for coil center with is able error correction for stacking

3) The coil will be raising for easy pick up by forks.

4) Automatic coil positioning.

B. Stacking machine

1) Strong and durable structure designing.

2) Manually feeding timber between the coil stacking.

3) Strong forks for picking up the coil

4) Mobile lifting coil picking, smoothandfast operation.

5) Mainly composed of a Gantry type mobile mechanism.

6) Gantry type shifting mechanism, ensure smooth movement of the steel coils.

7) Inside coil protector.

8) There is need timber block between thecoils.

9) Four supportive arms for protecting the coil in moving.

10) Accurate position for coil taking and stacking.

C. Conveyor station .

It is a conveyor for out feeding the palletized coils

² Max stacking height:1000mm (pallet height is included)

² Max stacking weight:6000kg

² Stacking platform:Conveyor

² Max stacking weight of single coil:3000kg

|

Item |

Data |

|

Min slit coil width that can be downended |

20-350mm |

|

Max horn extension |

app.1800mm |

|

Horn travel motor powered |

3.0Kw |

|

Linear motion slides/wheels/camrollers |

By Linear |

|

Lift powered |

Hydraulic |

|

Tilt powered |

Hydraulic |

|

Cycle time to downend coil |

60“ |

|

Conveyor length |

1600mm |

|

For covered rollers include |

roll diameter: 100mm, length:1600mm, covering material:PU,Roll centers:150mm |

|

Conveyor Motor |

2.2Kw |

|

Power supply |

380v 50Hz |

More coil packing lines: https://www.fhopepack.com/Automatic_Coil_packing_machinery.html

In steel processing, the slitting line is often a showcase of speed and precision. But once slit coils are produced, packaging them remains a labor-intensive, time-consuming task—unless it’s automated. The Automatic Slit Coil Packaging System closes that gap by transforming a manual bottleneck into a streamlined, intelligent, and operator-light process.

This system doesn’t just move steel—it redefines the efficiency, safety, and scalability of modern slitting operations. For manufacturers investing in smart factories, it's more than an upgrade—it's essential infrastructure.

In traditional lines, heavy slit coils require cranes, forklifts, and multiple operators for manual centering, strapping, and stacking. That process is slow, inconsistent, and unsafe.

The Automatic Slit Coil Packaging System integrates a full range of inline automation modules—from coil down-ending and weighing, to strapping, stacking, and pallet outfeed. With precision mechanics and centralized PLC control, the entire system can be operated and monitored by just one technician.

Slit coils arrive via conveyor

Centering table aligns coil with precision sensors (auto error correction)

Lift table raises coil for fork pickup

Gantry robot or forklift system retrieves coil

Coil is smoothly transferred to stacking station

Automatic application of steel or PET straps

Ensures coil integrity for transport and storage

Coils stacked one by one on timber-block-separated pallets

Gantry-type movement ensures smooth and accurate coil placement

Four supportive arms prevent coil damage during movement

Full pallet is automatically transferred to the dispatch zone

Ready for stretch wrapping or warehouse storage

| Feature | Description |

|---|---|

| Conveyor Type | Heavy-duty rollers with adjustable alignment |

| Centering Mechanism | Auto correction sensors with real-time feedback |

| Lifting Function | Hydraulic lift for accurate fork-level pickup |

| Coil Positioning | Auto-stop + safety interlock system |

| Feature | Description |

|---|---|

| Structure | Gantry-type with fork mechanism |

| Fork Strength | Engineered for heavy slit coil support |

| Coil Separator | Timber block (manual or semi-automatic) |

| Movement Precision | Servo-controlled horizontal & vertical travel |

| Safety | 4-arm coil protection + inside ring guide |

| Operator Input | Minimal—just timber placement if required |

| Operation | Throughput (Typical) | Automation Level | Operator Role |

|---|---|---|---|

| Coil Centering & Pickup | ≤ 20 coils/hour | Fully automatic | Monitor only |

| Coil Strapping | 1–2 straps/coil (optional) | Optional | Visual check |

| Coil Stacking on Pallet | 1–2 coils/min | Fully automatic | Insert timber blocks |

| Pallet Outfeed | Continuous | Fully automatic | None |

| Total Line Supervision | Entire packaging system | One operator | Central HMI control |

This packaging system is designed with Industry 4.0 readiness in mind. It supports:

Remote diagnostics & IoT integration

MES/ERP connectivity

Real-time production and downtime reporting

Predictive maintenance alerts

Error-proofing logic for coil type, size, and stacking format

All modules are interconnected through a central PLC + HMI system, allowing full control from a single panel—reducing training time, human error, and staffing needs.

“One operator can now manage an entire slit coil packaging section with greater precision than a crew of five,” notes a systems engineer at Fhope. “It’s not just automation—it’s operational freedom.”

| Key Benefit | Impact |

|---|---|

| Labor Reduction | From 3–5 operators to 1 |

| Safety Improvement | Less manual handling of heavy steel coils |

| Packaging Consistency | Every coil stacked and aligned identically |

| Time Savings | Up to 60% faster than manual processes |

| Floor Space Optimization | Linear, compact layout |

| ROI | < 18 months (typical) |

You’ve invested in high-speed slitting. Why stop short at packaging?

The Automatic Slit Coil Packaging System completes the vision of a smart, connected, and efficient steel processing line. With unmatched reliability and the ability to run with just one operator, it’s becoming a critical component for steel service centers and coil processing plants aiming to stay competitive in the age of intelligent manufacturing.

For tomorrow’s smart steel plant, automated slit coil handling is no longer optional—it’s operational strategy.

???? Contact Fhope today for system layout planning, ROI estimates, and turnkey integration support.

I'm online now.