Click to Chat

I'm online now.

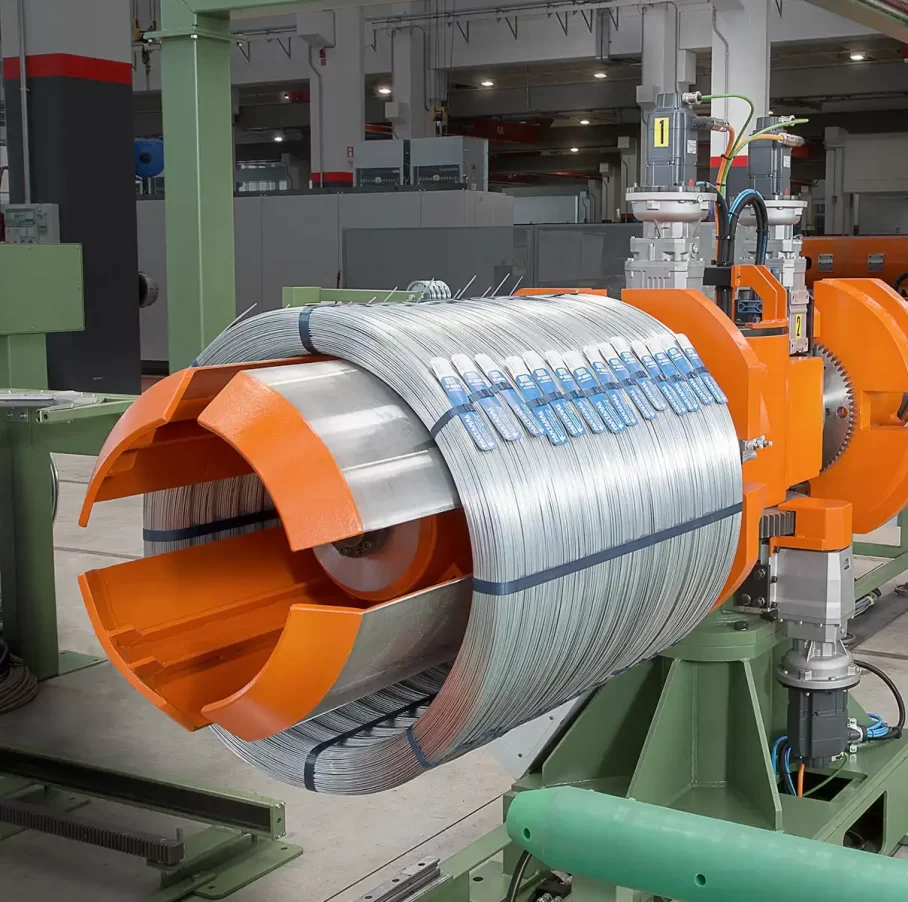

The wire coil packaging machine is a type of wrapping machine designed to cover packing material around a wire coil using an eye-through method. The machine is typically used in industries that manufacture wire coils for various applications. The process involves placing the wire coil on the machine's supportive roller and wrapping a protective layer of packing material around it by feeding the material through the coil's center. The wire coil wrapping machine can use various packaging materials, including paper, film, and knitted belt, which are customized based on the steel wire product's size and weight requirements. Automatic functions ensure even, tight application of the packing material at an efficient rate. By optimizing the wrapping material and process for each product, the machine delivers maximum protection for wire coils of all specifications. By considering your needs and drawing on our extensive industry experience, we offer tailored solutions for every customer.

The PLC and HMI in the wire coil packaging solution enable automatic operation while allowing users to control and modify packing machine parameters through the control system interface. Any errors are displayed on the interface, providing real-time feedback on the coil wrapping process.

With extensive experience and a proven track record, FHOPE designs and manufactures a wide range of steel wire coil compression, wrapping, and strapping machines. We offer customized solutions to meet unique customer requirements, including strapping with PET or steel belt, logo tapping, weighing, stacking, and more. FHOPE provides both semi-automatic and fully automatic options to maximize efficiency and cost-effectiveness, reducing power and material costs.

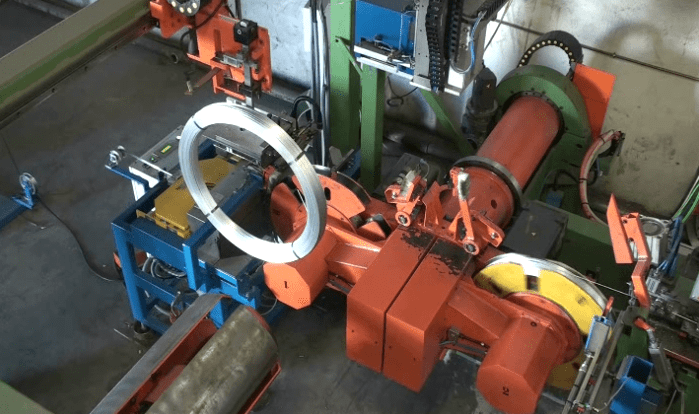

The horizontal PC wire coil packing machine is designed for steel wire coils with outer diameters of up to 2500 mm and weights of 1 to 3 tons. It is a ring-type c...

Both semi-automatic and full-automatic type can be provided. Specific design and plan will be made by our engineering team according to the data provided by the c...

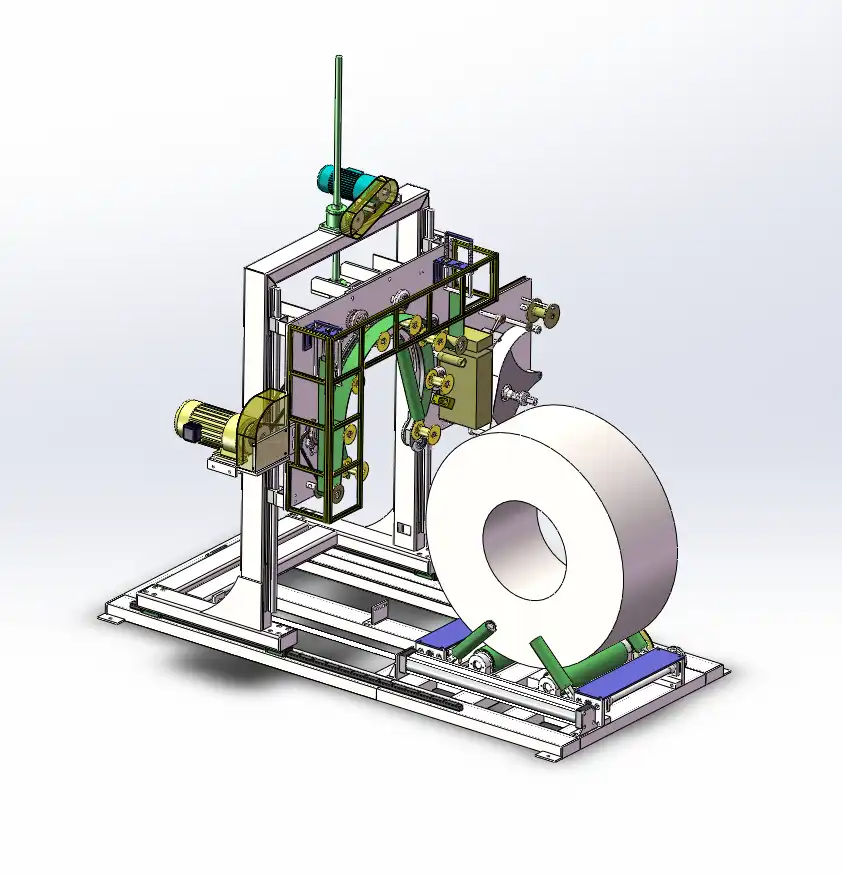

The FPW-800 is a highly efficient steel wire coil wrapping machine that comes with loading/unloading trolley equipment. It is specifically designed for packaging ...

The FPW-600 is a steel wire coil wrapping machine featuring a trolley for easy coil loading and unloading. Primarily used for packaging big prestressed concrete w...

FPW-500 series wire coil wrapping machine has trolley attached for loading and unloading. The electric components: Siemens PLC provides incomparable control of co...

The FPW series wire coil wrapping machine is specifically designed for packaging steel wire coils, copper coils, and other similar products. This highly efficient...

The FPW-300 is a wire coil ring wrapper intended for medium-sized coils. It is capable of wrapping coils with various packaging materials, such as LLDPE stretch f...

All of the machines provided by Fhope conform to CE guidelines and are designed using the latest technology and design criteria for industrial use. Fhope offers a...

This steel wire packing machine can wrap coils with paper and plastic film simultaneously. Its wrapping station can move up and down for safe and easy loading/unl...

The automatic winding machine, also known as a winder, is a device designed for wrapping various materials such as string, twine, cord, thread, yarn, rope, wire, ...

The strapping machine dispenses, tightens and seals polypropylene while coil in strapping position. The machine strap and joins the ends automatically with adjus...

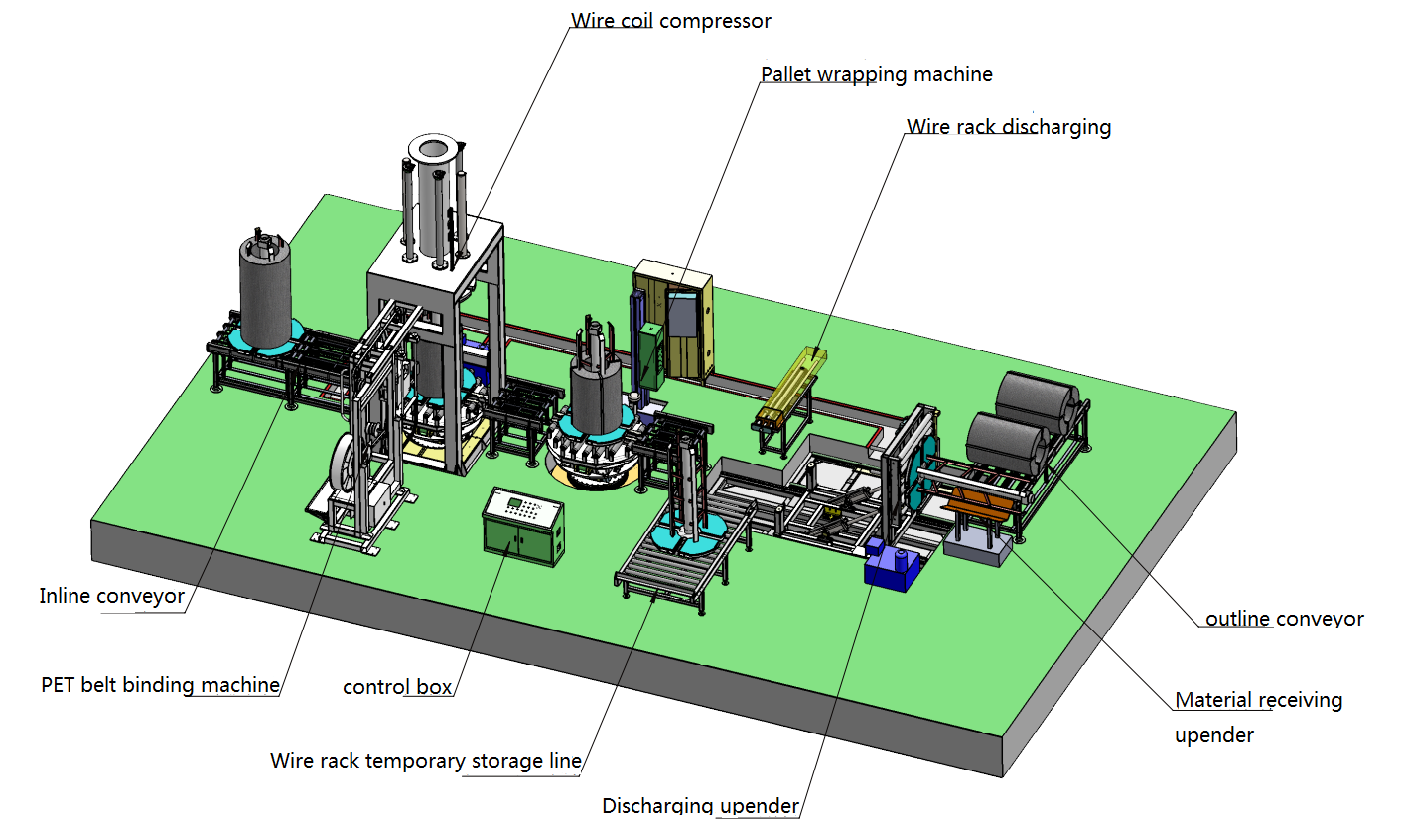

The automated steel wire coil packaging solutions designed for fullfill the automatic packing after the steel wire drawing. Driven by a commitment to innovation, ...

For Steel Wire Winding, Packing and stacking online. Different solution for special wire rewinding, JUST CONTACT US....

Designed for reliability and cost-effectiveness, this steel wire coil wrapping machine processes a broad spectrum of coil sizes and materials. Its operational core includes an advanced PLC control system and a user-friendly touchscreen, enabling rapid setup adjustments for different coil dimensions and wrap types. Shops processing small and lightweight wire coils will find this machine especially efficient, providing a practical tool to improve packaging consistency and speed.

Key Features:

Adjustable wrapping tension for optimal protection

Vertical steel wire coil packing, with manual coil loading and unloading

Foolproof operation that requires no complex installation

Engineered to package steel wire coils with enhanced precision and care, this system introduces a "coil ID to sky" packing orientation. This innovative approach directly addresses the challenge of gravity-induced deformation in softer wire types during the wrapping process, ensuring coil shape is maintained. For operational versatility, the wrapping station also features forward and backward adjustability to accommodate different setup requirements.

Key Features:

Horizontal Coil Loading: “ID to sky” setup protects coil shape from gravity-induced distortion.

360° Support Rollers: Enable stable rotation and uniform wrapping coverage.

Large Coil Compatibility: Designed to handle oversized wire coils with ease.

Customizable Design: Adaptable to your coil size, weight, and packaging specs.

Engineered for robust performance, this wire coil wrapping machine efficiently packages large, heavy coils ranging from 400mm to 1000mm in width. Its key feature is an integrated trolley system designed specifically to simplify the loading and unloading of substantial coil weights. This makes the machine exceptionally well-suited for workflows utilizing overhead cranes, improving both safety and material handling efficiency within the wrapping station.

Key Features:

It is an Online Coil Wrapping Machine and advanced packaging solution designed for seamless integration into production lines. With its built-in conveyor system, this machine effortlessly conveys wire coils to the wrapping station, automatically positions them for accurate wrapping, and ensures precise packing material counting and cutting. The streamlined packing process results in increased productivity and reduced labor costs.

Key Features:

It is Automatic rewinding packing systeme that is a revolutionary packaging solution that streamlines the entire process of rewinding wire from spools into smaller wire coils, followed by automatic strapping, wrapping, and stacking. That is an invaluable investment for optimize wire packaging processes while leveraging the benefits of advanced automation, data tracking, and ERP system integration.

Key Features:

The machine designed for efficiently winds and packs wire coils. It integrates automatic wire feeding, winding, cutting, and packaging into a single system, ensuring precise coil formation, high-speed operation, and optimized packing for various wire types and sizes..

It is an innovative packaging solution designed to optimize handling and packing of wire with spools. This advanced system incorporates automatic compacting and strapping, spool removal, and wire coil packing, significantly reducing manual labor and forklift handling requirements.

Key Features:

|

|

Choosing the appropriate wire coil wrapping equipment is a critical decision impacting handling efficiency, material usage, safety, and overall operational cost. Before investing, carefully evaluate the following key factors to ensure the selected system aligns with your specific production needs and workflow.

The way coils are transported to and from the wrapping station is a primary consideration that dictates machine compatibility.

The type and combination of packaging materials directly influence machine design and capabilities.

The degree of automation should match your throughput requirements, labor availability, and budget, while also considering future growth.

|

|

|

|

|

FPW-200-400 |

FPW-600/800 |

Our team will reply in 24 hours

![]() Email: info@fhopepack.com

Email: info@fhopepack.com

![]() Whatsapp: 0086-13951501635

Whatsapp: 0086-13951501635

I'm online now.