Automatic coil packing solution – The way to improve your coil packing from manually to automatically

The steel coil is an heavy load that is not easy to handling by manually. For safety and more efficiency coil packing, many factory looking for a solution to resove the problems caused by coil status. FHOPE provides coil packing system that designs according your packing requirement . There are different types packing line to connect the sliting line with coil downender, crene, forkman...We provide hot mill coil packing system too for achieving the highest efficiency. No matter coil information scaning or strapping, packing, our system are able to reduce huge amount of labor cost by flexiable system for handing and stacking. And we provide the solution to help you has a fast return on investment.Benefits of automatic coil packing line

1. Efficiency handling, packaging, palletizin...that works for different coil specification.2. Trackable in all steps and connectable with ERP system from packing to stocking.

3. Better packaging in coil surface, strapping and palletizing.

4. Safety operation.

please contact us at any time.

Benefits of automatic coil packing line

1. Efficiency handling, packaging, palletizin...that works for different coil specification.2. Trackable in all steps and connectable with ERP system from packing to stocking.

3. Better packaging in coil surface, strapping and palletizing.

4. Safety operation.

please contact us at any time.

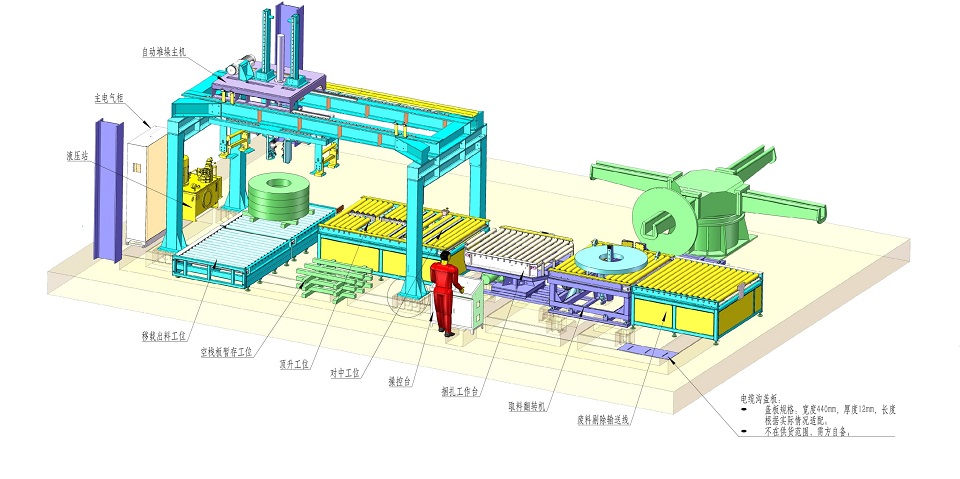

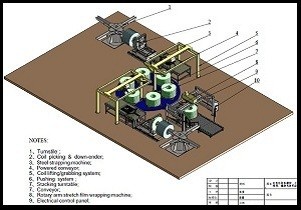

A. SLIT COIL HANDLING AND STACKING LINE

The solution is for making the coil handling and packing in a pipe line

The handling solution is mainly for picking up the coil from coil car, and moves the coil into stacking machine to replce the crane or forklifter. The key station is the coil stacking machine that is for stacking the coil one by one on pallet. That is more easy and safety that another handling ways.

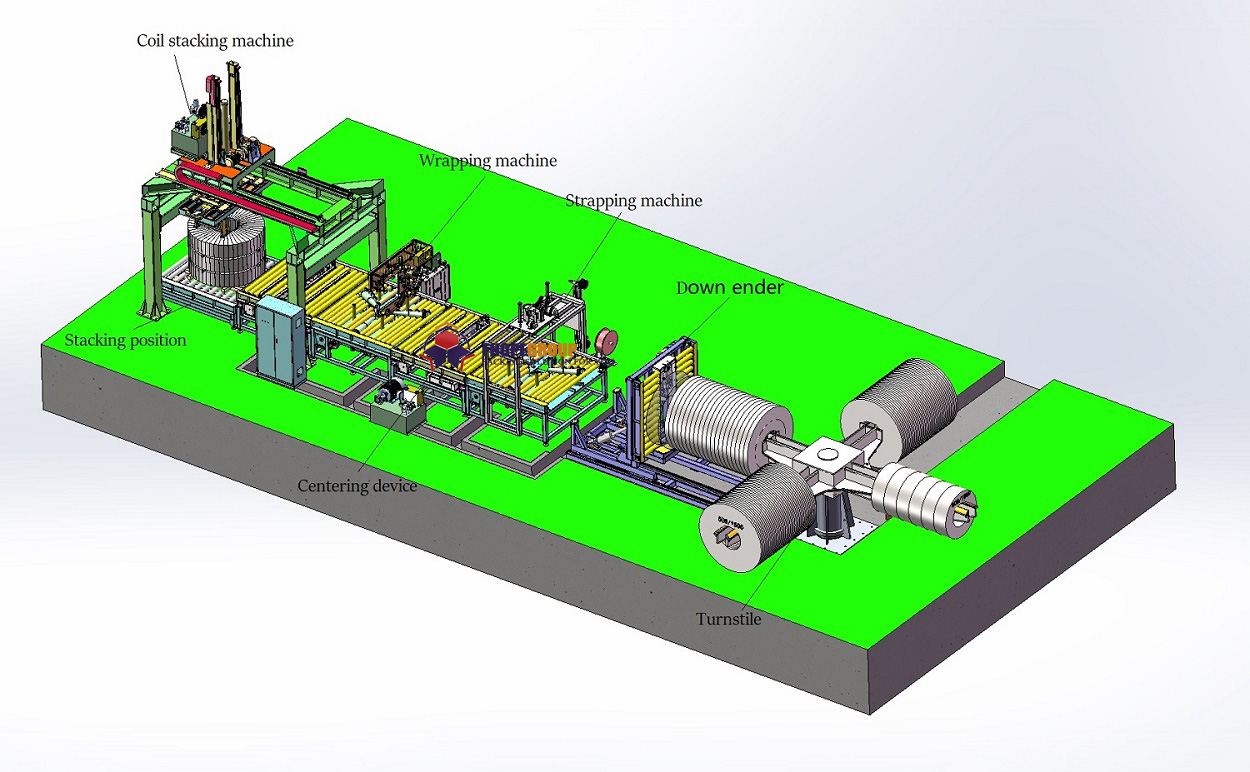

B. SLIT COIL WRAPPING AND STACKING LINE

The concept of packing line is an design for integral part of the coil packing machinery. The machine covers tight layers of packing materials over all surfaces of the coil. This tight layers of packing material avoids most of the air from the package. By reducing the amount of air in the package, covered protective packing material, the potential for moisture to form is reduced, thereby reducing the possibility of corrosion or water spots.

Automatic slitting coils packing solution with prefect ROI

FHOPE providing customized coil packing system that designs according different packaging goal and buddet level. The packing system just need 1-2 man for all operation steps. Accourding to the handling way the packing line can be diesigned with coil car feeding, crane loading, even forklifter in&out.

Handling speed: 70-120 sec per coil.

Max.coil Weight:6T

Strapping: By PET/STEEL

Packing material: Per requirement

Control level: Level 1-3

Iot: Yes

Compiticable with: MES, ERP

Space: per factory Layout

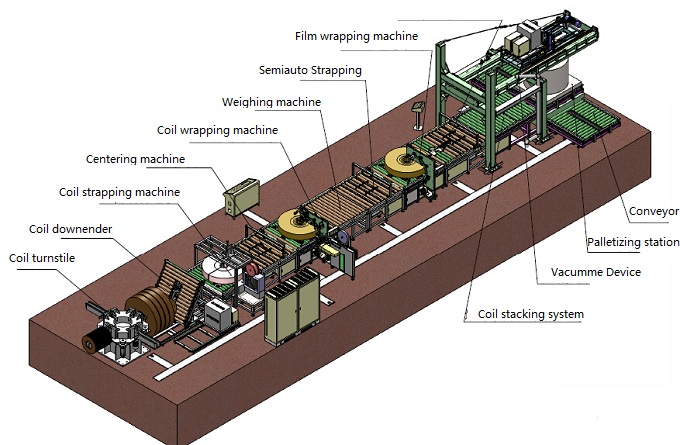

C. SLITTING COIL PACKING AND STACKING LINE

A second layer of packing material is then applied according requirement. The second layer of packing material holds the ancillary package in place and more protects the inner airtight layer of film. The outer layer shall be torn from handling damage. Besides the inner layer remains intact and thus the coil stays sealed and protected, because of the ancillary material is in between which is applied separately by the two layers,

Browse our entire range of solutions by selecting the areas that are right for you.

The typical requirement in the slitting coil packaging

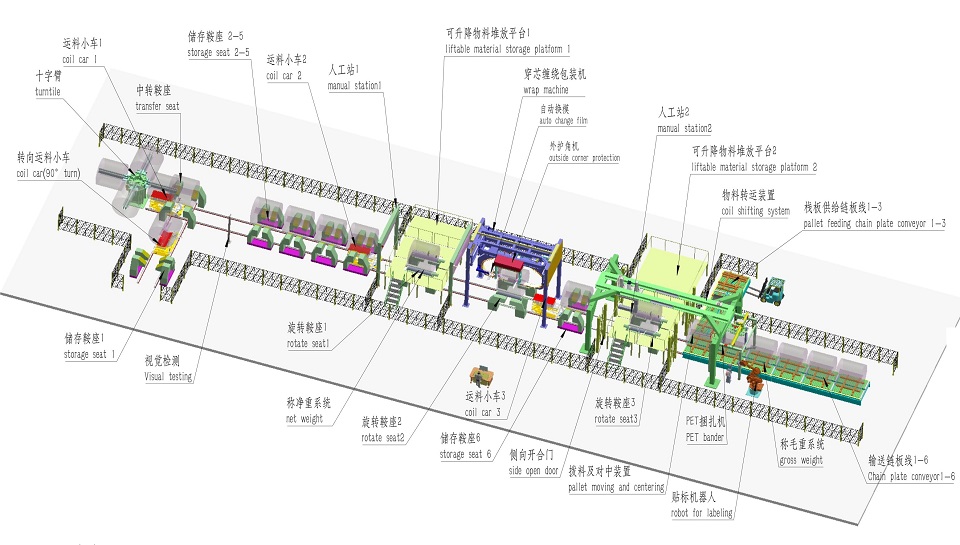

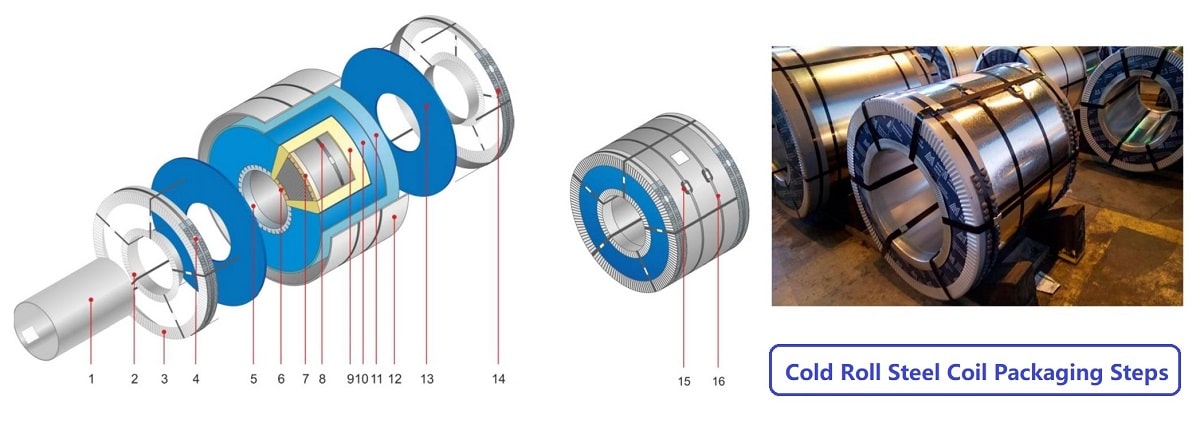

D. COLD ROLL COIL HANDLING AND PACKAGING LINE

The ancillary packing is can be applied too. This cold roll coil packaging may include protectors of outside diameter, protectors of inside diameter , protectors of side wall or belly wrap material. These materials can be integrated into the system to be applied automatically or applied manually . This ancillary packaging protects both the coil and the first layer of film The ancillary product can be made from plastics to maintain a completely recyclable package.

The typical packaging way of the cold roll steel coil packaging

2. ID steel edge protector

3. OD steel edge protector

4. OD edge protector strapping

5. ID cardboard protector

7. OD cardboard protector

8. Cold roll steel coil OD strapping

9. VCI paper covering

10. VCI film stretch wrapping

11. Cardboard OD covering

12. Steel sheet OD covering

13. Side cover

14. OD Edge protector

15. Cercumferece coil strapping

16. Radial coil strapping

There are solution to connect with your slitting line and warehouse for automatic handling, strapping, wrapping and stacking on pallets. Only one man is able operating the whole line in safety way.

.jpg)

Coil strapping machine Coil pallet stacker

The speed of ring and rollers are adjustable to accommodate materials varying in thickness. The conveyor belt or supportive roller can be raised or lowered and in some models, even tilted to the desired angle for packing. It can be equipped with an ink coding system , or an imprinter to record words, dates, and codes with each seal for each products. Speed of Automatic coil packing machinery are considerably faster much more than by manually , it is ideal equipment for projects which require minimal space and costs and higher production rates.

By machine - Automatic coil wrapping machinery or Coil Packing Machine

Find the right solution to fit your needs by selecting the type of machine you are interested in.

By industry--Find the right solution to your packaging needs by selecting your industry/market segment.

More coil packaging information

Related coil packing line video

Coil Packing Line

-

Automatic copper slitting coil strip packaging lineAutomatic copper slitting coil strip packaging line is specifically designed to package copper coils with care and precision. These coils are often bundled in large copper sheet coils and tightly coiled into smaller lengths once they are cut and slit. Our state-of-the-art technology streamlines the entire packaging process, ensur...

Product Inquiry

![]() Email: [email protected]

Email: [email protected]

![]() Whatsapp: 0086-13951501635

Whatsapp: 0086-13951501635