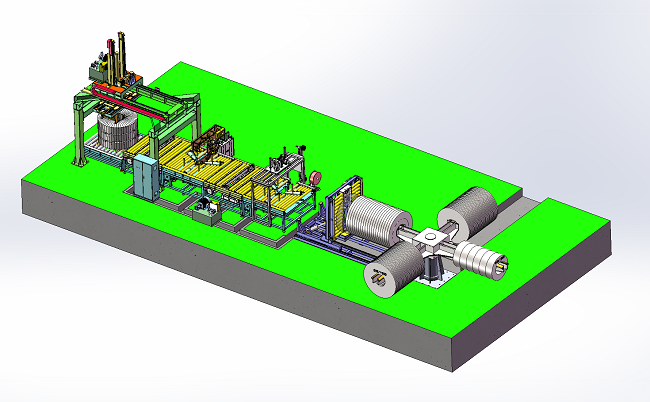

The video of the slit coil packing system in the customer factory that is for automatic coil pick up from turnstile and packing on the conveyor stream.

More slitting coil packing line: https://www.fhopepack.com/Automatic_Coil_packing_machinery.html

One of professional manufacturer for the steel slit coil packing line. The slit coil packing system work with online that connect to the coil car of the slitting machine. And it also works with offline for crane coil loading. Includes level one control system with IOT.

The solution: For max. coil weight 4000kg

Coil Strapping machine: BY PET

Coil stacking: Automatically

Coil pick up from turnstile:

• Coil clamps or vacuum arms positioned on a turnstile table pick up individual slit coils coming from the slitting line

• The grippers securely hold the coils during transport without distortion

Conveyor infeed:

• Conveyors transport the picked up coils to the packing line

• Buffer sections allow for fluctuations in coil output from the slitting line

Coil Strapping Machine:

• Applies steel or polyester straps around coil bundles to secure and contain them

• Consists of a strapping head with strap feeding mechanisms and tensioning rolls

• Features a sealing unit to seal the strap ends once tensioned

• Is controlled by a PLC to apply the correct tension for each coil size

Applying PET Straps:

• Suitable for strapping with polyester straps (PET) due to compatibility of sealing methods and tensioning forces

• PET straps are more economical and easier to handle compared to steel straps

• However they require proper tension and sealing to prevent loosening over time

Automatic Coil Stacking:

• Uses stacking frames, racks or shelves that the strapped coil bundles are placed onto

• Integrates stack position sensors that detect when a stack is full

• Incorporates grippers or manipulators that lower the coil bundle onto a stack

• Synchronizes the stack position with strapping operations via the PLC

Packing line:

• Coils are set down onto wrapping mandrels or coil frames

• Stretch film, cardboard sheets and end protectors are applied to the coils using wrapping machines

• Straps are applied around the outside diameter of the packed coils using automatic strapping machines

Conveyor outfeed:

• Fully packed coils are discharged onto outbound conveyors

• Conveyors transport the coils to storage or for further processing

Control system:

• A PLC controls all conveyors, wrapping and strapping machines in the line

• An HMI interface enables operators to monitor and adjust line settings

• Level 1 controls provide basic synchronization and fault detection

• IOT connectivity allows data collection and remote monitoring

Benefits of the automated packing line:

• Higher throughput compared to manual packing methods

• More consistent packing quality due to precision mechanics

• Less material waste from automatic wrapping and strapping

• Reduced labor costs by minimizing manual handling operations

• IOT connectivity enables condition monitoring and performance optimization