Streamline Your Operations: A Deep Dive into Automatic Steel Tube & Plastic Pipe Bagging Machines

Handling and packaging long, often heavy, steel tubes or plastic pipes presents unique challenges for manufacturers and distributors. Manual bagging is labor-intensive, prone to inconsistencies, and can expose products to damage during transit and storage. Fortunately, automated solutions like the Automatic Steel Tube and Plastic Pipe Bagging Machine offer a robust answer, significantly boosting efficiency, protection, and overall operational performance.

This article explores the technical capabilities, operational workflow, and tangible benefits of incorporating such machinery into your packaging line, drawing on practical insights relevant to professionals in the packaging world.

1. The Limitations of Manual Pipe Packaging

Before delving into automation, it's crucial to understand the drawbacks of traditional manual methods:

- High Labor Costs: Manual bagging requires significant personnel, especially for high-volume operations.

- Inconsistent Quality: Bag fit, sealing integrity, and overall package appearance can vary greatly between operators and shifts.

- Risk of Damage: Manual handling increases the likelihood of scratches, dents, or contamination of the pipes. Bagging might not be uniform, leaving sections exposed.

- Slow Throughput: Manual processes inevitably bottleneck production flow, limiting overall output capacity.

- Safety Concerns: Repetitive motions and handling heavy or awkward pipes can pose ergonomic risks to workers.

2. Introducing the Automated Solution: The Steel Tube & Plastic Pipe Bagger

The automatic bagging machine is engineered to receive individual pipes (or small pre-bundled groups), encase them securely in protective plastic film (typically polyethylene), and seal the bag – all with minimal human intervention.

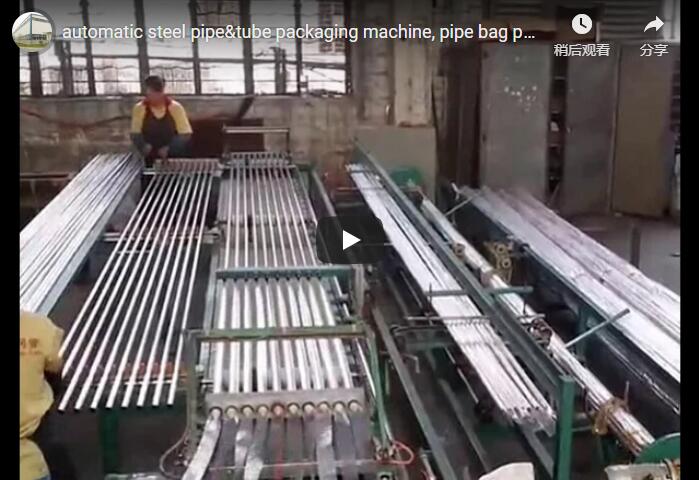

Watch the machine in action:

As demonstrated, the system uses a combination of conveyors, sensors, and sealing mechanisms to create a customized, protective sleeve around each pipe.

3. Key Features and Technical Specifications

Understanding the technical capabilities is vital for evaluating if a machine meets specific operational needs. Key parameters often include:

- Pipe Diameter Range: Specifies the minimum and maximum pipe diameters the machine can handle (e.g., 10mm - 150mm).

- Pipe Length Range: Defines the acceptable minimum and maximum pipe lengths (e.g., 1m - 6m or longer, depending on configuration).

- Packaging Material: Typically utilizes PE (Polyethylene) film rolls. Film thickness (gauge) and roll width capabilities are important specifications.

- Sealing Method: Commonly employs heat sealing bars (impulse or constant heat) to create secure end seals and potentially longitudinal seals for fully enclosed bags.

- Throughput Speed: Measured in pipes per minute (PPM) or meters per minute, depending on the operational mode (e.g., 5-15 pipes per minute).

- Control System: Often utilizes a PLC (Programmable Logic Controller) with an HMI (Human-Machine Interface) for easy operation, parameter adjustments, and diagnostics.

- Sensor Technology: Photoelectric sensors detect pipe presence, length, and position to trigger feeding, film dispensing, and sealing actions accurately.

- Power Requirements: Standard industrial power specifications (e.g., 380V/50Hz/3-Phase, subject to regional standards).

- Air Consumption: Pneumatic systems often require compressed air at a specific pressure and volume.

4. Operational Workflow: A Step-by-Step Look

While specific designs vary, a typical operational sequence involves:

- Infeed: Pipes are fed onto the machine's infeed conveyor, often automatically from an upstream process or manually placed.

- Detection & Positioning: Sensors detect the leading edge of the pipe, triggering the system. Guides ensure proper alignment.

- Film Dispensing: The machine draws the required length of plastic film from a roll.

- Bag Formation: The film is typically formed into a tube around the pipe.

- Sealing: Sealing bars create secure seals at the front and rear ends of the pipe, encapsulating it within the bag. For sleeve-style bagging, only end seals might be needed. For fully enclosed bags, a longitudinal seal is also made.

- Cutting: The film is cut to separate the bagged pipe from the film roll.

- Outfeed: The bagged pipe is discharged onto an outfeed conveyor or table, ready for bundling, palletizing, or storage.

5. Tangible Benefits: Driving Efficiency and Protection

Investing in an automatic pipe bagging machine delivers significant advantages:

- Enhanced Product Protection: Uniform, tight-fitting bags shield pipes from dust, moisture, scratches, and UV exposure (if using UV-inhibitor film), preserving product quality during handling and storage.

- Significant Labor Savings & ROI: Automation drastically reduces the need for manual labor in the bagging process, allowing personnel to be reallocated to higher-value tasks. This results in a measurable Return on Investment (ROI), often within a short timeframe.

- Increased Throughput and Efficiency: The machine operates consistently at speeds significantly faster than manual methods, eliminating bottlenecks and increasing overall production capacity.

- Improved Workplace Safety: Automating the handling and bagging process reduces ergonomic risks associated with manual labor.

- Consistent & Professional Packaging: Every pipe receives the same high-quality packaging, enhancing brand image and customer satisfaction upon receipt.

big bearing packing machine with vci film 6. Choosing the Right Pipe Bagging Solution

Selecting the appropriate machine requires careful consideration of:

- Production Volume: Match machine throughput to your output needs.

- Pipe Characteristics: Ensure the machine accommodates your specific range of pipe diameters, lengths, and weights.

- Material Type: Confirm compatibility with both steel and plastic pipes if handling both.

- Space Availability: Consider the machine's footprint and required clearances.

- Budget: Balance initial investment against long-term labor savings and efficiency gains.

- Integration Needs: Determine if the machine needs to interface with existing upstream (e.g., extrusion lines, cutting saws) or downstream equipment (e.g., bundling machines, labeling systems, palletizers).

7. Integration into the Packaging Line

For maximum efficiency, the automatic pipe bagging machine is often integrated into a larger automated packaging line. It can receive pipes directly from production or cutting stations and feed bagged products seamlessly into subsequent processes like automatic bundling, strapping, labeling, and palletizing, creating a fully streamlined end-of-line packaging solution.

Conclusion

The Automatic Steel Tube and Plastic Pipe Bagging Machine is more than just a piece of equipment; it's a strategic investment for companies seeking to optimize their pipe packaging operations. By automating a traditionally labor-intensive process, businesses can achieve substantial improvements in efficiency, product protection, safety, and consistency. Evaluating your specific needs against the technical capabilities and benefits outlined here will help determine how this technology can best serve your operational goals.

For further information or to discuss your specific pipe packaging challenges:

Explore Automated Pipe Packaging Solutions

Contact us: info@fhopepack.com