Dydraulic Box and Barrel Dumper

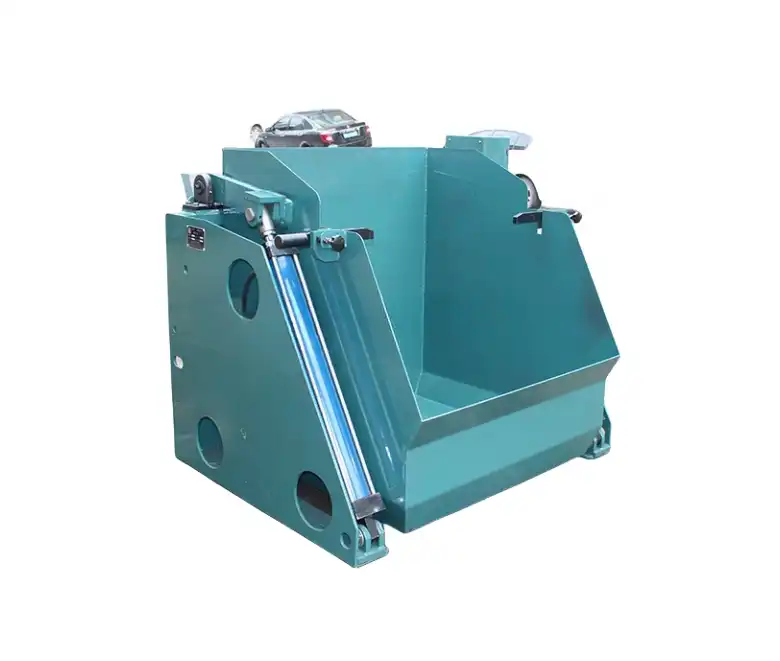

hydraulic box dumper is an industrious piece of equipment designed to enhance efficiency and safety in material handling. It operates by using a hydraulic mechanism to lift and tilt containers, typically boxes or bins, to dump their contents into a designated area or receptacle. This process minimizes the need for manual labor, reducing the risk of injury and improving workflow.

The robust design typically features a heavy-duty steel construction, ensuring durability and reliability in demanding industrial environments. With various models available, these dumpers can accommodate different weight capacities and box sizes, making them a versatile solution for a wide range of applications in warehouses, manufacturing plants, and beyond.

1. Dydraulic Box and Barrel Dumper

Dydraulic Box and Barrel Dumper make it easy to dump product from shipping containers into target containers or vats so that the product can be used for reprocessing or production. Portable drum dumpers help employees spread parts onto production lines or meter liquids to specific products. Our Dydraulic Box and Barrel Dumper offer the following product features.

Functionality:

- 135-degree dumping angle for complete emptying of product from shipping containers

-

Can be designed as stationary or portable depending on customer requirements

- Tipping heights of 36", 48", and 60" and capacities of 2,500 or 4,000 lbs.

Operation:

- Push button pendant with magnetic back

-

Limit switches for up and down positive stops

- Optional speed control XMD screw valve with Bluetooth connectivity

Safety settings:

- Adjustable fixing bar for securing the container

-

Line-mounted CB valve for securing the basket

- Heavy duty bracket stop with rubber bumper

Hydraulic Dumper

-

Hydraulic Tote DumperHydraulic Tote Dumper The hydraulic dumping machine is kind of suitcase, box type device, robust in such all-welded steel construction and uses materials to bear heavy and harsh industrial environments and afford long-lasting usability the pallet truck is easily accessible to facilitate the efficient loading and unloading of cont...

-

Hydraulic Box DumperHydraulic Box Dumper Designed for rotated height of 2743/3250/3760mm and load capacity of 2t, 4t, 6t, t he hydraulic box dumper is constructed with all welded steel, ensuring a sturdy and durable machine frame . It contains reformatory safety features and offers easy approachability for pallet truck discharged and un discharged ....

-

Hydraulic box & container dumperHydraulic box container dumper The hydraulic box dumper is typically used in industrial settings where there is a need to unload or empty the contents of containers quickly and safely. It is a machine commonly used in lots of industrial settings, for example warehouses, manufacturing facilities, and distribution centers. It allow...

Frequently asked questions

A hydraulic box dumper is a piece of industrial equipment used to lift and tilt containers, like boxes or bins, to dump their contents efficiently and safely.

It operates using a hydraulic mechanism that lifts and tilts the container to a designated angle, allowing the contents to be emptied out.

They are commonly used in warehouses, manufacturing plants, recycling operations, and anywhere bulk material handling is required.

Capacities vary, but models can typically handle between 2,000 to 6,000 pounds.

Yes, many models offer various dump heights, commonly ranging from 36" to 72".

Yes, hydraulic box dumpers come in various sizes to accommodate different container dimensions and volumes.

Most dumpers have an adjustable restraining bar or hold-down mechanism to secure various container sizes.

Safety features may include lockable on/off controls, protective mesh side screens, and dual flow control valves for smooth operation.

Many manufacturers offer custom chute sizes to fit specific needs.

They typically require an electrical power source for the hydraulic system, often 460V AC, 3 Phase, 60 Hz, but other options may be available.

Yes, they can handle a variety of containers, including gaylord boxes, totes, and crates, with adjustable features to accommodate different sizes.

Cycle times vary, but many can complete a dump cycle within one minute, enhancing workflow efficiency.

They are typically made of heavy-duty, welded steel for durability and long-term use.

Yes, the dumping angle can usually be controlled up to a certain degree, often around 135 degrees, for precise material handling.

Some manufacturers may offer mobile or portable versions, but typically these are stationary units due to their size and power requirements.

Consider the weight and size of the materials you'll be handling, the desired dump height, space constraints, and any specific features you need, like custom chute sizes or adjustable restraining bars.

Regular maintenance typically includes checking hydraulic fluid levels, inspecting for leaks or wear, ensuring safety features are functioning, and occasionally checking and tightening bolts and connections.

Product Inquiry

![]() Email: [email protected]

Email: [email protected]

![]() Whatsapp: 0086-13951501635

Whatsapp: 0086-13951501635