Click to Chat

I'm online now.

Fhopepack Innovation

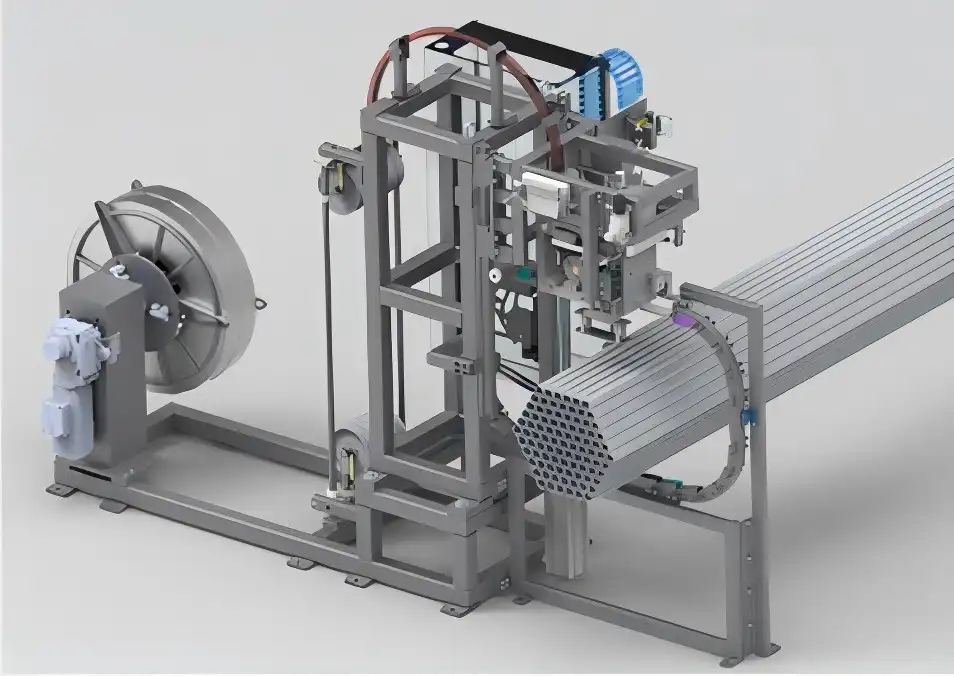

Full-automatic steel strapping machine is equipped with a reliable and well-tested strapping head that has been proven to be effective in the metallurgical industry. With its advanced features and efficient operation, this machine provides businesses with a reliable and cost-effective solution for their strapping needs. Trust us to provide you with high-quality and innovative packaging solutions f

This is the solution special designed for automatic steel pipe bundle strapping. The strapping machine equipped the strapping head that was well tested and proved by metallurgical industry. FHOPE technician team providing customized designing, manufacturing, installation, commissioning and local on-site service.

Description:

1.Strapping Head:

The strapping had is FH-32NH that is the strapping wrapping buckle.That provide the strong binding force for heavy steel coil and avoiding the connect broken. It own a high strapping successful rate. That using pneumatic motor perfect works in the high temperature working environment.Simple and reliable.

Powerful strapping head:

|

Drive |

Pneumatic |

|

Steel belt feeding speed |

App.1.5m/S |

|

Belt tightening speed |

App. 105mm/S |

|

Strapping head weight |

198Kg |

|

Buckle storage |

180 PCS |

|

Power supply |

380V, 50Hz |

|

Strapping belt reel |

drive by motor |

2.Steel Belt:

|

Strap Material Steel Belt |

GB/T25820-201 or YB/T025-2002 |

|

Strap Size Double Belt |

Width 31.75±0.127mm |

|

Thickness |

0.8mm |

|

Coil |

ID 406mm OD 800mm Width 190mm |

|

Tensile strength |

not less than 900 mpa |

|

Elongation |

not less than 10% |

|

Carbon cold rolled steel |

tensile strength ≥950 N/mm, elongation ≥12 |

|

Medium carbon cold rolled steel |

tensile strength ≥ 750 N/mm, elongation ≥ 18 |

3. Main Parts:

|

Strapping Head |

Swing type strapping head for different OD strapping |

|

Machine Frame |

Durable and strong structure. Strapping head fix at the side way of the machine frame. The arch of the strapping machine is able expand and shrink for strapping. That the coil position adjustment by the walking beam. |

|

Belt feeding system |

Steel belt reel storage and automatic feeding |

|

Orbital Arch |

Special designed orbital arch for steel belt getting through that is easy and reliable with less maintain requirement in long time running |

|

Control system |

PLC,touch screen, sensors with automation program that is able connect with the production line for automatic running and interlocking. |

|

Note |

The machine designed follows the machine in the video provided |

|

Bottom arch adjustment |

by pneumatic |

|

Mode |

Automatically and Manually |

|

Top arch opening and closing |

by pneumatic |

|

Reliable tested designing |

Strong structure works for high tension running |

|

Orbital arch system |

After belt in-feeding into arch, well guiding and passing the orbital |

|

Strapping belt |

Width:32mm,Thickness:0.8-1.1mm |

|

High Tension Force |

4000~20000N |

|

Strapping Breaking force |

75% of steel belt tensile strength |

The automatic strapping machine is automatically positioned at a fixed point and performs each strapping operation as the strapping object moves. It be composed of Siemens PLC and HMI for operation, strapping effect beautiful and firm, high speed and to improve packaging line high efficiency, and reduces waste and saves costs.

I'm online now.