Advancing Steel Pipe Logistics: Automated Bundling for Galvanized Steel

The efficient handling and packaging of steel pipes, particularly galvanized varieties requiring careful surface treatment, present significant challenges in modern manufacturing and logistics operations. Manual bundling methods are often labor-intensive, inconsistent, and pose potential safety risks. Addressing these challenges, automated solutions like the steel pipe bundling machine developed by FHOPE represent a leap forward in operational efficiency and product integrity.

Engineering Principles in Automated Pipe Bundling

Automated pipe bundling systems leverage core engineering principles from material handling, robotics, and control systems to streamline the packaging process. The fundamental goal is to receive individual pipes, count them accurately, arrange them into a stable geometric configuration (often hexagonal for optimal density and stability, referencing principles similar to those discussed in material packing efficiency studies), and securely fasten the bundle for transport and storage.

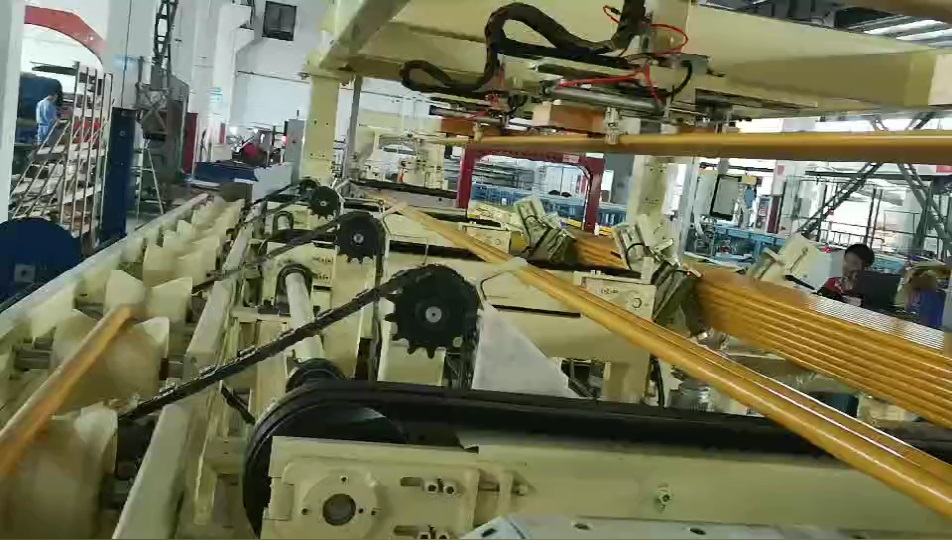

Operational Workflow and Key Mechanisms

The typical operational sequence of such a machine involves several distinct stages:

- Infeed Conveying: Pipes are transferred from upstream processes (e.g., production lines, galvanizing tanks) onto the bundling machine's infeed conveyor system. Sensors often detect pipe presence and initiate the cycle.

- Pipe Counting and Layer Formation: Advanced sensor arrays or mechanical counting mechanisms ensure the precise number of pipes per layer is accumulated. Mechanisms may include indexing fingers or gates. Research into optical counting systems (similar to those described in automated inventory patents) highlights the accuracy achievable.

- Bundle Shaping/Formation: Pipes are arranged into the desired bundle shape. For hexagonal bundles, specialized jigs or pusher arms gently maneuver pipes into nested layers. The design must account for varying pipe diameters while maintaining bundle integrity, a challenge addressed in mechanical design literature focusing on adjustable fixtures.

- Strapping/Banding: Once formed, the bundle is secured using steel or PET strapping. Automated strapping heads, guided by PLC logic, tension, seal, and cut the strap. Multiple straps are typically applied along the bundle length for stability during handling. The kinematics of strapping head movement are critical for cycle time optimization.

- Bundle Discharge: The completed bundle is transferred onto an exit conveyor or storage rack, ready for subsequent logistical operations like crane lifting or forklift transport.

Handling Galvanized Steel: A Critical Consideration

Galvanized steel pipes require special handling to preserve the protective zinc coating, crucial for corrosion resistance (as standardized by ASTM A123/A123M for hot-dip galvanizing). Automated bundling machines designed for these products incorporate features to minimize surface damage:

- Non-Marring Contact Surfaces: Rollers, guides, and clamping mechanisms often utilize materials like high-density polyethylene (HDPE) or nylon to prevent scratching or abrasion of the zinc layer.

- Controlled Forces: Actuation systems (pneumatic, hydraulic, or electric) are carefully calibrated to apply sufficient force for secure bundling without deforming the pipes or compromising the coating. Force feedback sensors may be employed, echoing advancements seen in robotic assembly (documented in robotics journals).

- Smooth Transitions: Conveyor transfers and positioning movements are designed to be smooth, avoiding impacts that could damage the pipe ends or surface.

Technical Specifications and Performance Metrics

While specific parameters vary by model and application, typical specifications for automated steel pipe bundling machines include:

- Pipe Diameter Range: Handling capabilities often span from small conduits (e.g., 1/2 inch) to larger pipes (e.g., 6 inches or more).

- Pipe Length Range: Accommodates standard pipe lengths, often with adjustments for variations (e.g., 6 meters to 12 meters).

- Bundle Configuration: Typically hexagonal, but square or rectangular configurations may be possible.

- Maximum Bundle Weight: Capacity can range from hundreds to thousands of kilograms, depending on machine design and structural integrity.

- Cycle Time: A key performance indicator, representing the time to form and strap one complete bundle. Optimized systems aim for high throughput to match production line speeds.

- Control System: Commonly utilizes Programmable Logic Controllers (PLCs) with Human-Machine Interfaces (HMIs) for operation, diagnostics, and parameter adjustments (e.g., bundle size recipes).

Benefits Beyond Efficiency

The implementation of automated steel pipe bundling systems offers multifaceted advantages:

- Enhanced Productivity: Significant reduction in manual labor and faster cycle times compared to manual methods.

- Improved Safety: Reduces manual handling of heavy pipes, minimizing risks of strains, crush injuries, and repetitive motion disorders.

- Consistent Bundle Quality: Ensures uniform bundle shape, size, and strap tension, improving stability during transport and storage.

- Reduced Product Damage: Careful handling minimizes scratches and dents, particularly important for coated products like galvanized steel.

- Labor Optimization: Frees up personnel for higher-value tasks within the facility.

- System Integration: Designed for integration into larger automated production and warehouse management systems (WMS), supporting Industry 4.0 initiatives.

FHOPE's development in steel pipe bundling technology, particularly for galvanized steel, provides a robust solution that addresses critical industry needs for efficiency, safety, and product quality preservation, aligning with the demands of modern infrastructure and manufacturing sectors.

https://www.fhopepack.com/Automatic-pipe-bundle-packing-line.html