Slit Coil Packaging Line for Slitting Service Center with Automatic Labeling System Connected to ERP

Metal slitting service centers operate in a demanding environment where efficiency, accuracy, and product integrity are paramount. The handling and packaging of slit coils present unique challenges. Traditional manual methods are often labor-intensive, susceptible to inconsistencies, and pose risks of product damage and incorrect identification. As documented in industry analyses, such as those found in Modern Metals magazine, optimizing downstream operations like packaging is critical for maintaining competitiveness.

The Challenges in Slit Coil Handling and Identification

Manual packaging processes for slit coils are frequently bottlenecks. Key issues include:

- Operational Inefficiency: Manual wrapping, strapping, and labeling consume significant time and labor resources, slowing overall throughput.

- Inconsistent Package Quality: Variations in manual application of protective materials (like VCI paper or stretch film) can compromise coil protection during transit and storage.

- Labeling Errors: Manual data entry and label application are prone to human error, leading to misidentification, shipment delays, and potential inventory discrepancies. Research highlighted in logistics journals consistently points to automated identification as a key factor in reducing supply chain errors.

- Traceability Gaps: Ensuring accurate tracking of each slit coil from production through to the customer requires robust identification. Manual systems often lack the real-time data integration needed for complete traceability, a growing requirement for quality management systems (e.g., ISO 9001).

Implementing an Integrated Automated Solution

To overcome these hurdles, advanced slitting service centers are adopting automated packaging lines featuring integrated labeling systems directly linked to their Enterprise Resource Planning (ERP) platforms. This integrated approach addresses the core challenges systematically.

Automated Packaging Line: Features and Benefits

The foundation of the solution is a robust Slit Coil Packaging Line designed for the specific demands of metal coils. Key operational stages typically automated include:

- Coil Handling and Preparation: Automated conveyors, centering devices, and potential weighing stations ensure smooth and safe coil transport.

- Protective Wrapping: Application of VCI materials or stretch film using orbital wrappers ensures consistent, tight protection against environmental factors. Patent literature (e.g., patents related to automated wrapping mechanisms like US Patent X,XXX,XXX) often details innovations focused on film savings and wrap integrity.

- Strapping: Automated radial or through-eye strapping (using PET or steel strapping) secures the coil and any protective layers.

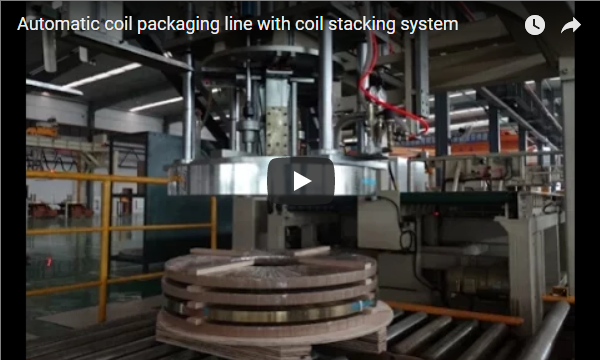

- Stacking and Palletizing: Automated systems can stack smaller coils or place larger coils onto pallets for efficient storage and shipment.

Automatic Labeling System: Ensuring Accuracy and Compliance

A critical subsystem is the automatic labeling unit. This typically involves:

- Print-and-Apply Technology: Industrial thermal transfer printers create durable labels resistant to oil, grease, and handling abrasion. These labels contain vital information mandated by customer or industry standards (e.g., GS1, AIAG for automotive).

- Data Integration: The labeling system receives coil-specific data directly from the ERP system. This eliminates manual keying and ensures label information (e.g., Coil ID, weight, grade, dimensions, customer PO) perfectly matches the production record.

- Precise Application: Automated applicators ensure labels are placed consistently and securely on the coil package.

ERP Connectivity: The Data Backbone

The seamless connection between the packaging line's control system (PLC) and the company's ERP system is fundamental. This integration, often achieved through standard protocols like OPC-UA or custom middleware, facilitates:

- Real-time Data Exchange: Production orders from the ERP trigger packaging and labeling instructions. Upon completion, the system updates the ERP with the status, weight, and unique ID of the packaged coil.

- Inventory Accuracy: Real-time updates ensure the ERP reflects the true status of finished goods, improving inventory management and order fulfillment accuracy.

- Enhanced Traceability: A complete digital thread is created for each coil, linking production data to the final packaged product, simplifying quality control and recall management if necessary. Studies published in journals like the International Journal of Production Research often emphasize the role of ERP integration in achieving end-to-end supply chain visibility.

Addressing Operational Deficiencies with Automation

The lack of an integrated, automated system directly leads to tangible operational problems:

- Reduced Throughput: Manual processes create bottlenecks, limiting the overall capacity of the slitting center.

- Increased Errors: Manual labeling and data handling inevitably lead to higher error rates, impacting customer satisfaction and potentially incurring costs for rework or returns.

- Traceability Challenges: Difficulty in tracking specific coils hinders quality assurance and complicates compliance requirements.

- Higher Labor Costs: Significant manual effort is required for packaging and labeling tasks.

- Potential Safety Risks: Manual handling of heavy coils can pose ergonomic risks to personnel.

Conclusion: Strategic Value of Integrated Packaging Automation

Investing in a slit coil packaging line with an integrated automatic labeling system connected to ERP is not merely an operational upgrade; it is a strategic imperative for modern slitting service centers. This technology directly addresses core industry challenges by:

- Boosting Efficiency: Dramatically reducing cycle times and labor requirements.

- Enhancing Accuracy: Minimizing errors in packaging and labeling, ensuring data integrity.

- Improving Product Protection: Providing consistent, high-quality packaging.

- Strengthening Traceability: Offering complete visibility throughout the coil's journey.

By leveraging automation and seamless data integration, as demonstrated in the video, slitting service centers can achieve significant improvements in operational performance, cost-effectiveness, and customer satisfaction, positioning themselves for sustained success in a competitive market. The proper implementation and ongoing maintenance of these systems, drawing on best practices outlined in resources like Packaging World, are key to realizing their full potential.