Mastering Load Containment: A Deep Dive into the Semi-Automatic Rotary Arm Stretch Wrapper

Ensuring the stability and security of palletized loads during transit and storage is a critical challenge across numerous industries. Damage during handling not only leads to product loss but can also create significant safety hazards. Semi-automatic rotary arm stretch wrappers offer a robust and efficient solution, particularly for loads that are unstable, heavy, or unusually shaped.

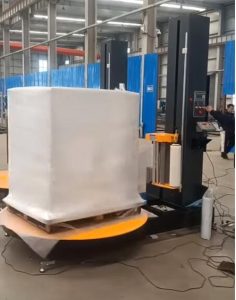

Watch the Fhope semi-automatic rotary arm wrapper in action:

Fhope Packaging Machinery stands as a world-renowned manufacturer specializing in advanced stretch packaging systems. Our expertise lies in developing robust mechanisms and applications utilizing stretch film technology, widely adopted, particularly within the corrugated industry, to protect and unitize loads effectively.

1. Understanding the Semi-Automatic Rotary Arm Advantage

Unlike traditional turntable stretch wrappers where the pallet rotates, a rotary arm wrapper keeps the load stationary on the floor or conveyor. An overhead arm equipped with the stretch film carriage revolves around the pallet. This fundamental difference makes it the ideal choice for:

- Unstable or Tall Loads: Eliminates the centrifugal force that can topple insecure loads on a turntable.

- Very Heavy Loads: The floor supports the load's weight, bypassing the weight limitations of a turntable.

- Washdown Environments: Keeping the load stationary can simplify wrapping in areas requiring frequent cleaning.

The "semi-automatic" aspect means an operator typically positions the pallet, attaches the film tail, initiates the wrap cycle via a control panel or remote, and then cuts the film upon completion.

2. Key Features and Technical Specifications (Typical)

While specific configurations vary, Fhope semi-automatic rotary arm wrappers generally incorporate features designed for performance and reliability:

- Wrapping Arm Speed: Variable, often up to 15 RPM, allowing adjustment based on load type and stability.

- Maximum Load Size (L x W x H): Generous capacities, often accommodating standard pallet dimensions and extended heights (e.g., up to 2400mm or higher).

- Maximum Load Weight: Virtually unlimited, as the load rests directly on the floor.

- Film Delivery System: Powered pre-stretch carriage (e.g., 200%-300% pre-stretch) significantly reduces film consumption and improves load containment force.

- Control System: PLC (Programmable Logic Controller) with user-friendly HMI (Human Machine Interface) for setting parameters like top/bottom wraps, arm speed, and film tension.

- Construction: Heavy-duty steel frame and robust components for industrial environments.

- Safety Features: May include safety fences, flashing lights during operation, and emergency stops. Options for light curtains are often available.

- Power Requirements: Typically operates on standard industrial power (e.g., 220V/380V, 3-Phase).

3. Operational Advantages: Insights from the Floor

Choosing a semi-automatic rotary arm wrapper translates to tangible benefits in daily operations:

- Superior Load Containment: Keeping the load static ensures even film application and tension, crucial for challenging loads.

- Enhanced Worker Safety: Reduces manual handling risks associated with hand wrapping and minimizes potential product falls compared to turntable systems with unstable loads.

- Optimized Film Usage: Powered pre-stretch significantly lowers consumable costs compared to hand wrapping or machines without pre-stretch.

- Increased Throughput: Faster and more consistent than manual wrapping, improving overall packaging line efficiency.

- Operational Flexibility: Easily handles a wide variety of pallet load shapes, sizes, and weights without complex adjustments.

4. Ideal Applications Across Industries

The unique capabilities of the semi-automatic rotary arm stretch wrapper make it suitable for diverse sectors:

- Logistics and Distribution Centers: Handling mixed pallet loads, heavy items, or tall stacks.

- Corrugated Products: Wrapping large or potentially unstable stacks of boxes or sheets.

- Building Materials: Securing bags of cement, tiles, bricks, or insulation materials.

- Food and Beverage: Wrapping pallets of cartons, cans, or bottles, especially tall or multi-layered loads.

- Manufacturing: Unitizing finished goods, raw materials, or components of varying stability.

5. Why Fhope? Commitment to Quality and Customization

Fhope offers a diverse portfolio of stretch films in various sizes and types, suitable for automatic, semi-automatic, and fully automatic stretch packaging systems. Our commitment extends beyond standard machinery:

- Tailored Solutions: We understand that standard equipment doesn't fit every need. Our experienced sales team, equipment service department, customer service team, and engineering department collaborate to design and build packaging systems tailored to specific customer requirements.

- Robust Protection: Our systems are engineered to provide high-quality protection, safeguarding loads from dust, moisture, and shifting during transit and storage.

- Quality Assurance: We prioritize reliability, efficiency, and cost-effectiveness, ensuring our stretch packaging systems deliver maximum protection and operational value.

pallet stretch wrapping machine with weighing scale 6. Making the Right Choice

A semi-automatic rotary arm wrapper is often the optimal solution when dealing frequently with heavy, tall, or unstable loads, or when operational flexibility is key. It provides a significant step up in efficiency and safety from manual wrapping without the full investment required for fully automated systems.

In summary, Fhope provides leading semi-automatic rotary arm stretch wrapping solutions designed for stability, efficiency, and reliability. We offer customized systems backed by dedicated technical teams to meet the unique demands of various industries, ensuring maximum load protection throughout the supply chain.

For more details on specific rotary arm models:

https://www.fhopepack.com/Rotary-arm-wrapping-machine/

Contact us for inquiries:

info@fhopepack.com