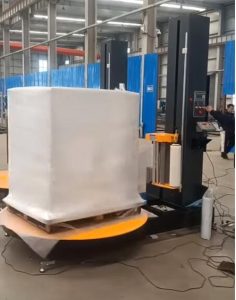

Optimizing Load Stability: A Closer Look at the Semi-Automatic Pallet Stretch Wrapper A100

Effective pallet wrapping is crucial for load stability, product protection during transit, and overall warehouse efficiency. While manual wrapping can be inconsistent and labor-intensive, fully automatic systems might be overkill for some operations. The semi-automatic pallet stretch wrapper, like the Fhope A100 model, offers a practical balance, enhancing consistency and throughput compared to hand wrapping.

Fhope Packing Machinery, based in China, specializes in stretch wrapping and pallet wrapping solutions. With significant experience, reflected in the production of over 1680 sets of pallet stretch wrappers, Fhope manufactures both semi-automatic and fully automatic systems catering to diverse packaging needs.

1. Understanding the A100 Semi-Automatic Stretch Wrapper

The A100 is designed for operations where an operator places the pallet load onto the turntable, attaches the film tail, and initiates the wrap cycle via a control panel. The machine then automatically wraps the load according to preset parameters before the operator cuts the film and removes the secured pallet.

Key Components and Function:

- Turntable: The rotating platform where the pallet is placed. Its controlled rotation ensures even film application around the load.

- Mast and Film Carriage: The mast supports the vertically moving film carriage. The carriage holds the stretch film roll and controls its tension and vertical movement to cover the entire height of the load.

- Control System: Allows the operator to set parameters such as turntable speed, carriage ascent/descent speed, number of top/bottom wraps, and film tension (depending on the specific carriage type).

- Film Delivery System: This can range from simple friction brake systems to powered pre-stretch units (check specific A100 configuration) that elongate the film before application, maximizing film yield and ensuring tighter load containment.

Typical Operating Sequence:

- The operator places the pallet load onto the turntable using a forklift or pallet jack.

- The film tail is threaded through the carriage and attached securely to the pallet base or load.

- The operator selects the desired wrap program or parameters on the control panel and presses the start button.

- The turntable begins rotating, and the film carriage moves vertically (typically up, then down) applying the stretch film.

- The machine completes the pre-set number of top and bottom wraps.

- Once the cycle is complete, the turntable stops in the home position.

- The operator cuts the film tail and wipes it against the load.

- The secured pallet is removed from the turntable.

2. Core Technical Specifications (Typical A100 Configuration)

While exact specifications can vary, typical parameters for a machine like the A100 include:

- Turntable Diameter: 1500mm (Standard), other sizes often available.

- Turntable Speed: 3-12 RPM (Adjustable).

- Mast Height (Max Wrapping Height): 2100mm or 2400mm (Standard), taller options possible.

- Maximum Load Weight: 1500kg - 2000kg.

- Maximum Load Dimensions (LxW): Dependent on turntable size (e.g., compatible with 1200mm x 1200mm pallets).

- Film Carriage: Mechanical Brake or Powered Pre-stretch (e.g., up to 250% pre-stretch ratio).

- Stretch Film Compatibility: Standard 500mm width LLDPE machine film rolls.

- Power Supply: Typically 220V/1Ph/50Hz or specified requirement.

- Control: PLC (Programmable Logic Controller) based.

pallet stretch wrapping machine with weighing scale 3. Practical Application and Operator Experience

Semi-automatic wrappers like the A100 provide significant advantages over manual wrapping:

- Consistency: Machine control ensures uniform film tension and overlap, crucial for consistent load integrity. Manual wrapping quality can vary greatly between operators and even from the top to the bottom of the same pallet.

- Film Efficiency: Powered pre-stretch systems (if equipped) can significantly reduce film consumption compared to manual or basic brake systems. Consistent application avoids excessive film use.

- Improved Throughput: While requiring an operator, the wrapping cycle itself is faster and less physically demanding than manual wrapping, allowing operators to handle more pallets per hour.

- Operator Safety: Reduces the physical strain and dizziness associated with manually walking around a pallet multiple times.

Tips for Optimal Use:

- Load Placement: Ensure the pallet is centered on the turntable to maintain balance during rotation.

- Film Threading: Follow the correct path outlined in the machine manual, especially for pre-stretch units, to ensure proper tension and elongation.

- Parameter Setting: Adjust turntable speed, carriage speed, and wrap counts based on the load characteristics (weight, stability, height) for optimal containment without damaging the product.

- Regular Checks: Periodically inspect rollers, belts, and safety sensors. Keep the area around the turntable clear.

4. Leveraging Experience for Reliable Solutions

Fhope's experience across numerous installations translates into understanding diverse application requirements. This informs design choices related to durability, ease of use, and maintenance accessibility. Customization capabilities are key; whether needing a larger turntable for oversized loads, a taller mast for high pallets, integrated weigh scales, or specific control features, experience allows for tailoring the base A100 design effectively.

As a dedicated supplier, Fhope focuses on providing stretch wrapping machinery that meets specific operational demands, drawing upon extensive knowledge in both semi-automatic and fully integrated automatic lines.

For more detailed information on stretch wrapping solutions:

https://www.fhopepack.com/Stretch_wrapping_machine.html

Contact for inquiries:

info@fhopepack.com