How Does a Vertical Steel Coil Packing Line Work for Slit Coil Handling?

Struggling with slow packaging speeds, high labor costs, or damaged slit coils during storage and transport? You're not alone. Many manufacturers face these issues with outdated or manual coil packing methods.

A vertical steel coil packing line automates the entire packaging process for slit coils, including lifting, wrapping, stacking, and palletizing. It improves speed, ensures consistent protection, and lowers operational costs.

This article will walk you through how this system works, why it’s ideal for slit coils, and what makes it a superior solution for steel processors like you.

Why is Vertical Packing Ideal for Slit Coils?

Traditional methods just don't cut it anymore. They're slow, risky, and inconsistent. If you handle slit coils, you need a system that's fast, secure, and built for precision.

Vertical packing works better for slit coils because it keeps them upright and stable. This reduces the risk of edge damage, makes stacking easier, and speeds up packaging.

What makes vertical orientation more reliable?

Slit coils are narrower and often have sharp edges. When stored horizontally, they can deform or get scratched. Vertical storage and packing solve this.

Key Differences Between Vertical and Horizontal Coil Packing

| Factor | Vertical Coil Packing Line | Horizontal Coil Packing Method |

|---|---|---|

| Coil Orientation | Stands coils upright | Lays coils flat |

| Edge Protection | Better edge support | Higher risk of edge damage |

| Space Efficiency | Easier to stack and align | Takes up more floor space |

| Automation Compatibility | Fully compatible with robotics | Limited automation options |

| Safety | Safer coil movement and storage | Manual handling increases risks |

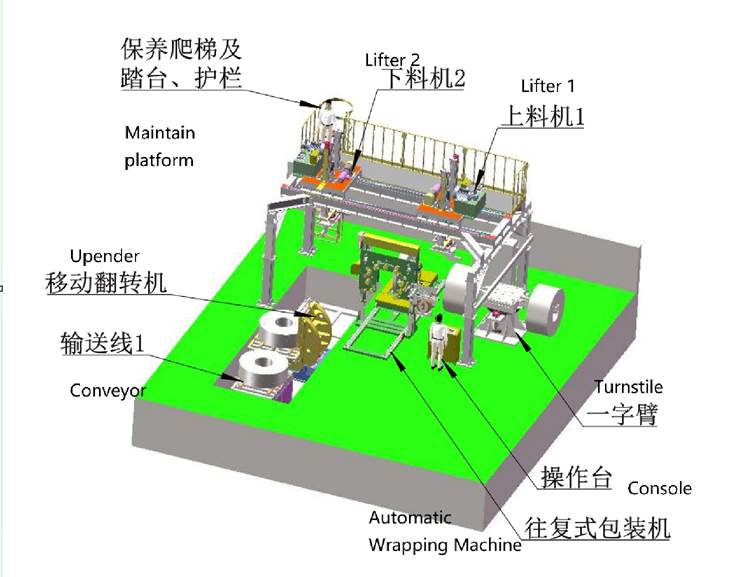

The vertical coil packing line we build at Fhopepack includes automatic upenders and dual-head coil lifters to ensure safe and accurate positioning. This minimizes operator intervention and coil damage. Once the coil is standing, wrapping starts immediately. Wrapping in vertical orientation reduces stress on the material and ensures uniform coverage.

The upender also assists in transferring wrapped coils to pallets. This process is controlled with a single console, minimizing the need for multiple operators.

If your factory handles slit coils every day, switching to vertical packing is not just a recommendation. It's a must.

How Does Automation Improve Coil Packaging Speed and Safety?

Manually moving, wrapping, and stacking coils is risky and slow. If your line is still mostly manual, you're likely losing time and money every day.

Automated coil packing lines handle everything from coil loading to final palletizing. They improve packaging speed, reduce errors, and enhance safety by eliminating manual steps.

How does full automation benefit daily operations?

Automation isn’t just about speed. It’s about consistency and safety. A well-designed vertical packing line removes guesswork and manual errors from the process.

Components of an Automated Vertical Coil Packing Line

| Process Step | Automated Equipment Involved | Functionality |

|---|---|---|

| Coil Lifting | Dual Head Crane Lifter | Picks and positions coils quickly |

| Coil Loading | Transfer Trolley | Transfers coils onto the wrapping station |

| Coil Wrapping | Vertical Wrapping Machine | Wraps coils with stretch film or paper |

| Coil Sorting | Automatic Picking Arm | Moves coils to stack or next station |

| Palletizing | Coil Upender + Lifter | Turns and places coils on pallets |

| Out-feeding | Conveyor System + Control Console | Sends packed coils out automatically |

From the first second in our demonstration video, you can see the flow: the crane lifter handles the coil, the trolley delivers it, and then the wrapping station does its job. The coil doesn’t stop. It’s picked, wrapped, turned, and palletized.

This non-stop movement is what enables our line to run 24 hours a day with minimal supervision. It’s especially effective for steel mills that operate on tight delivery schedules.

More importantly, this means fewer workers in dangerous positions. Manual lifting and moving of heavy steel coils is a major safety risk. Automation eliminates that.

What Makes Our Vertical Coil Packing Line Customizable?

No two factories are the same. Coil dimensions, wrapping needs, and space constraints vary. Off-the-shelf systems won’t give you the efficiency or safety you need.

Fhopepack’s vertical coil packing line is fully customizable. You can adjust coil sizes, wrapping materials, packing speeds, and layout to match your operation.

How can a custom design reduce downtime?

A one-size-fits-all packing machine might look cheaper upfront, but it becomes expensive when it causes frequent stops, jams, or rework. Our goal is to make the machine fit your process—not the other way around.

Customizable Features in Our Vertical Coil Packing Line

| Feature | Customization Options | Why It Matters |

|---|---|---|

| Coil Size Range | From 200mm to 1200mm OD | Match your specific slit coil specifications |

| Wrapping Materials | Paper, stretch film, laminated film | Choose based on corrosion, storage, or transport |

| Packing Speed | Adjustable via control panel | Optimize for production flow |

| Space Configuration | L-shaped, linear, U-shaped | Fit into existing factory layout |

| Integration Capability | Connect with MES/ERP systems | Synchronize with production data |

| Operator Interface | Touchscreen HMI with multilingual support | Easier for global teams to operate |

Our engineering team works with you from the start. We study your coil specs, factory floor plan, and production volume. Then we design the layout.

The coil upender, for example, can be placed either before or after wrapping, depending on your flow. Some clients require dual wrapping stations; others prefer one high-speed station. Everything is up to you.

When a machine fits your needs perfectly, breakdowns go down, productivity goes up.

Conclusion

If you handle slit coils and want a packaging system that’s faster, safer, and more reliable, our vertical steel coil packing line is your best solution. It's built to meet your needs, customizable from the ground up, and proven in 24/7 operations.

Whether you're managing a steel mill, a service center, or a distribution warehouse, don’t wait to optimize your packaging process. Let FHOPEPACK help you find the right solution today.

Contact us to get a tailored proposal and system layout: www.fhopepack.com