Streamlining Operations: Integrating Automated Packaging for Galvanized Steel Wire Coils

Handling and packaging galvanized steel wire coils presents unique challenges for manufacturers and fabricators. The inherent weight, bulk, and susceptibility of the galvanized coating to damage demand robust, efficient, and safe handling solutions. Traditional manual methods often fall short, leading to inefficiencies, potential product damage, and increased risk of worker injury. Implementing an automated galvanized steel wire packaging line addresses these issues head-on, offering a significant upgrade in operational efficiency and product integrity.

Research published in journals like Wire Journal International and echoed in industry best practices highlights the critical need for consistent packaging to protect the zinc coating, which is essential for the wire's corrosion resistance. Inconsistent manual wrapping can lead to exposed areas or insufficient tension, compromising protection during storage and transit. Automated systems, as demonstrated in various patent filings for coil handling apparatus (e.g., referencing concepts for automated coil transfer and wrapping mechanisms), ensure repeatable, optimized packaging cycles.

Core Benefits of Automated Galvanized Wire Packaging

Transitioning to an automated packaging line delivers tangible advantages across the production workflow:

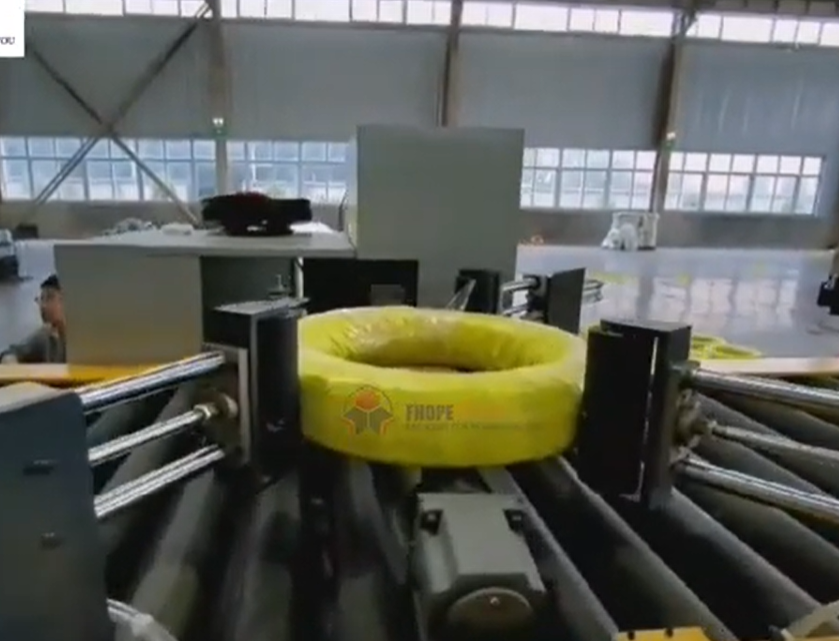

- Enhanced Product Protection: Automated stretch wrapping applies film with consistent tension and overlap, creating a secure, weather-resistant barrier. This minimizes the risk of mechanical damage and environmental corrosion to the galvanized surface, ensuring the wire reaches the end-user in optimal condition. Advanced systems can incorporate Vapor Corrosion Inhibitor (VCI) films for added protection, a technique supported by studies on corrosion prevention in metal packaging.

- Increased Throughput and Efficiency: Automation drastically reduces the time required for packaging each coil compared to manual methods. Typical systems can process coils significantly faster, integrating weighing, wrapping, and labeling into a seamless flow. This boosts overall plant output and reduces bottlenecks, a key metric discussed frequently in publications like The Fabricator focusing on lean manufacturing.

- Improved Worker Safety: Manual handling of heavy steel coils (often exceeding 1000 kg) poses significant ergonomic risks. Automation eliminates the need for manual lifting, pushing, and wrapping, drastically reducing the potential for strains, sprains, and other musculoskeletal injuries, aligning with OSHA guidelines for safe material handling.

- Optimized Material Usage: Modern stretch wrapping technology often incorporates powered pre-stretch capabilities (stretching the film before application), which can significantly reduce film consumption per coil compared to manual or less sophisticated wrapping methods, leading to direct cost savings. Efficiencies can range from 150% to over 300% pre-stretch, maximizing film yield.

- Process Consistency and Quality Control: Automation removes the variability inherent in manual processes. Every coil is packaged to the same specification, ensuring consistent presentation and protection. Integrated weighing systems provide accurate data for shipping and inventory management, while automated labeling ensures clear identification and traceability.

Anatomy of an Automated Packaging Line: Key Stages

A typical automated galvanized steel wire packaging line integrates several key functions:

- Coil Loading & Positioning: Coils are typically loaded onto the line's infeed conveyor or designated station via forklift, C-hook, or an upstream automated transfer system. Sensors (often photoelectric or laser-based) detect the coil's presence and ensure it is correctly positioned and centered before proceeding to the wrapping station. Accurate centering is crucial for stable and effective wrapping.

- Wrapping Station: This is the core of the line. Common configurations include:

- Turntable Systems: The coil rotates on a platform while a stationary mast dispenses stretch film.

- Rotary Arm Systems: The coil remains stationary while an arm rotates around it, applying the film. This is often preferred for very heavy or unstable loads.

The film delivery system features adjustable tension control and pre-stretch rollers to optimize film usage and load containment.

- Weighing: An integrated weigh-scale module, often situated within the conveyor system immediately after wrapping, captures the precise weight of the packaged coil for documentation and logistics.

- Labeling (Optional): Automated print-and-apply labelers can affix identification tags with barcodes, weight information, production data, and customer details directly onto the wrapped coil.

- Stacking & Offloading: Depending on the level of automation, the line may conclude with the coil simply exiting onto an accumulation conveyor for pickup, or it may incorporate an automated lifting and stacking mechanism to prepare coils for warehousing or direct shipment.

Implementing the Right Solution

Selecting and implementing an automated galvanized steel wire packaging line requires careful consideration of specific operational needs:

- Coil Specifications: Maximum/minimum coil diameter, width, and weight.

- Throughput Requirements: Coils per hour needed to match production output.

- Packaging Requirements: Type of film (standard LLDPE, VCI, UV-resistant), number of wraps, desired wrap pattern.

- Integration Needs: Compatibility with existing plant control systems (PLCs), MES (Manufacturing Execution Systems), or ERP (Enterprise Resource Planning) software for data exchange.

Investing in an automated Galvanized Steel Wire Packaging line represents a strategic move towards modernizing operations. It directly addresses key challenges in handling these specialized products, enhancing efficiency, safety, and product quality – critical factors for success in today's competitive steel industry.

For more details on tailoring a system to your specific requirements, please contact info@fhopepack.com